Contents

Approved by John Heim

Revised 12/21

4.1 Policy

4.2 Scope

4.3 Applicability

4.4 Exceptions

4.5 Roles and Responsibilities

4.6 Definitions

4.7 Required Work Processes

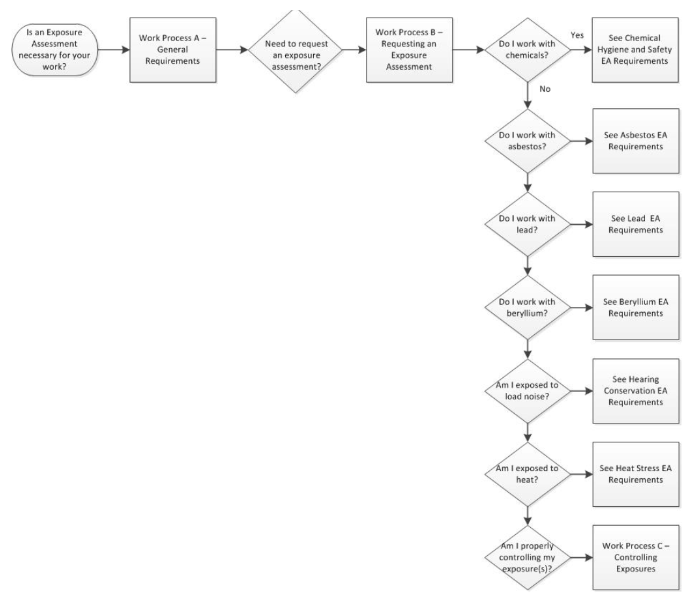

- Work Process A. General Requirements

- Work Process B. Exposure and Hazard Assessment Records

- Work Process C. Controlling Exposures

4.8 Source Requirements

4.9 Reference Documents

Note:

🚩🚩 Denotes a new section

🚩 Denotes the beginning of changed text within a section

🛑 Denotes the end of changed text within a section

_____________________

4.1 Policy

This policy describes Berkeley Lab’s approach to evaluating chemical and physical workplace health hazards at the Laboratory and or during Laboratory-sponsored work at other locations.

Berkeley Lab’s Exposure Assessment policy requires that Laboratory personnel exposure to chemical and physical workplace hazards not exceed established occupational exposure limits. The Exposure Assessment policy further requires that exposures be minimized through hazard elimination, engineering controls, personal protective equipment (PPE), and administrative controls.

Occupational exposures addressed by this policy include, but are not limited to, chemicals and physical agents (e.g., noise, hot and cold extremes, non-ionizing radiation). Assessments for confined spaces, lasers, ergonomics, biological agents, and radiological exposures are handled by their respective programs.

4.2 Scope

Berkeley Lab is committed to maintaining a safe and healthful workplace. Part of that commitment involves limiting exposures to materials or agents that could be associated with health hazards. The Health and Safety Department is responsible for evaluating exposures to non-radiological agents, and the Radiation Protection Group evaluates exposures to radiation-related hazards. The process involves recognizing or identifying potential exposures, assessing worker and workplace exposure, and comparing the exposure with established exposure limits or other applicable criteria. The findings may be used to establish or validate appropriate controls for the operations evaluated in this process.

In addition to chemicals such as beryllium, asbestos, and lead, which are addressed by separate Berkeley Lab programs and policies, overexposure to many other substances could be harmful. Physical agents such as noise, non-ionizing radiation (e.g., radio-frequency or microwave radiation), and thermal (heat or cold) stress can induce injury if a worker is overexposed.

Threshold Limit Values® (2016), as set forth by the American Conference of Governmental Industrial Hygienists (ACGIH), are used at Berkeley Lab. Exposure Limits as described in Title 8 California Code of Regulations, Section 5155 Airborne Contaminants, and related sections, are also used at Berkeley Lab.

4.3 Applicability

This policy applies to Berkeley Lab line managers, supervisors, Activity/Project Leads, employees, and affiliates who might be exposed to chemical or physical hazards, or who are responsible for managing exposures for workers, during work performed at Berkeley Lab or during Laboratory-sponsored work.

4.4 Exceptions

None

4.5 Roles and Responsibilities

| Role | Responsibility |

Activity Leads and Project Leads |

|

Exposure Assessment Subject Matter Expert | Develop and administer the exposure assessment program and this policy, along with its implementing documents |

| EHS Technical Program Subject Matter Experts |

|

Health and Safety Representatives |

|

Line Managers | Ensure that persons within their areas of responsibility comply with this policy and its implementing documents, and notify the appropriate EHS Division Subject Matter Experts or Health and Safety Representatives of process changes that may affect employee exposures |

Potentially Exposed Workers | Request an Exposure Assessment when a concern is present regarding potential exposure; perform work in accordance with the controls and procedures defined in work planning documents (e.g,, WPC Activities), and follow guidance and work practices provided in workplace training (such as On The Job training) to evaluate and control exposures |

Supervisors | Request an exposure assessment when a concern is present regarding potential exposure; and ensure that persons within their areas of responsibility comply with this policy and its implementing documents, and have completed the required training prior to beginning work. |

4.6 Definitions

| Term | Definition |

| Baseline Exposure Assessment | A Baseline Exposure Assessment is a process to screen activities to help determine associated risks and hazards. These assessments are generally qualitative, although some quantitative data (collection or review) may be involved. |

| Chemical Agents | Includes all chemicals used at the Laboratory (or in Laboratory-sponsored work). This includes pure chemicals, mixtures (such as paint or cleaning agents), and materials such as asbestos, silica, and engineered nanomaterials. |

| Engineered Nanomaterials | Discrete materials having structures with at least one dimension between 1 and 100 nanometers, and intentionally created, as opposed to those that are naturally or incidentally formed. Engineered nanomaterials do not include larger materials that may have nanoscale features (e.g., etched silicon wafers), biomolecules (e.g., proteins, nucleic acids, and carbohydrates), or materials with Occupational Exposure Limits (OELs) that address nano-size particles for that substance. |

| Exposure | Inhalation, ingestion, absorption, injection, or contact with a chemical, biological, or physical agent |

| Exposure Assessment | The process of defining exposure profiles and judging the acceptability of workplace exposures to environmental agents. These assessments may be quantitative, semi-quantitative, or qualitative. These assessments are generally conducted by an EHS professional, which may include industrial hygienists or safety engineers. These assessments may be conducted for representative employees and are not required to be conducted for each individual. In all cases, employees have full access to exposure-monitoring information, including situations where an individual’s exposure is not monitored. |

| Industrial Hygiene | The art and science of anticipation, recognition, evaluation, and control of occupational health hazards (including exposures to chemicals, noise, and non-ionizing radiation). |

| Occupational Exposure Limit (OEL) | The maximum concentration of an air contaminant to which working people can be exposed for a specified time interval, usually the maximum average exposure allowed throughout an entire 8-hour shift. OELs are typically PELs or TLVs, which are also defined in this section. In the absence of formally recognized or regulatory-defined OELs, a chemical manufacturer may establish an exposure limit that is appropriate to use. Alternatively, the occupational health staff will have to determine or develop an appropriate protective level. This process often involves industrial hygiene, occupational medicine, and toxicology staff members. The National Institute for Occupational Safety and Health also publishes Recommended Exposure Limits (RELs), which may be evaluated for use. |

| Permissible Exposure Limit (PEL) | The Cal/OSHA permissible exposure limits are exposure levels for employee exposure in the workplace. Permissible exposure limits for airborne concentrations of hazardous materials are addressed in Title 8 California Code of Regulations, Section 5155, et.al. |

| Physical Agents | Agents such as noise, hot and cold extremes, and non-ionizing radiation (e.g., radio frequency, electromagnetic, microwave, and magnetic fields). Laser exposure is addressed by the Laser Safety Program (refer to PUB-3000, Chapter 16). |

| Professional Judgment | The application and appropriate use of knowledge gained from formal education, experience, observation, experimentation, inference, peer review, and analogy. It allows an experienced industrial hygienist with incomplete or a minimum amount of data to estimate worker exposure in nearly any scenario (adapted from DOE Guide G 440.1 and AIHA A Strategy for Assessing and Managing Occupational Exposures, Fourth Edition (2015)), although such judgments and their basis should be documented. |

| Qualitative Exposure Assessment | The estimation of exposure determinants based on integration of available information and professional judgment (adapted from DOE Guide G 440.1-3, Occupational Exposure Assessment). |

| Quantitative Exposure Assessment | The determination of exposure based on collection and quantitative analysis of data sufficient to adequately characterize exposures (adapted from DOE Guide G 440.1-3 and AIHA A Strategy for Assessing and Managing Occupational Exposures, Fourth Edition (2015)). |

| Similar Exposure Group (SEG) | A Similar Exposure Group (SEG) is a group of workers having the same general exposure profile for an agent based on the similarity of tasks being performed, and the similarity of the way in which they perform the tasks. The workers use the same general work practices and engineering controls when performing the tasks. |

| Task | For purposes of workplace evaluations and setting priorities, a job (or portion of a job) involving a discrete agent or set of agents to which workers may be exposed. The terms “activity” (not to be confused with WPC Activity) and “operation” are sometimes used in a similar manner. |

| Threshold Limit Values® (TLVs) | Airborne concentrations of materials to which typical workers may be repeatedly exposed without adverse health effects. TLVs are not intended to represent fine lines between safe and dangerous exposures. These values are developed and published by the American Conference of Governmental Industrial Hygienists (ACGIH). There are different values established for eight-hour time-weighted averages, ceilings, and Short-Term Exposure Limits (STELs). Other TLVs are available for non-chemical exposures, such as noise and non-ionizing radiation. |

| Work Planning and Control (WPC) | Work Planning and Control (WPC) is a program to implement integrated safety management (ISM). The main goals of WP&C are the following: All hazards are analyzed and controlled All workers demonstrate that they are qualified to perform activities All work is authorized |

| WPC Activity | A work planning and work authorization document used at LBNL to define work scopes, the hazards and associated controls, and to authorize workers to conduct the work. |

| WPC Activity Lead | Person responsible for directing, training, and overseeing the work and activities of one or more workers. Activity Leads provide instruction on working safely and the precautions necessary to use equipment and facilities safely and effectively. |

4.7 Required Work Processes

Work Process A. General Requirements

Every Berkeley Lab worker has a right to a safe workplace. In addition to physical hazards, this includes protection from overexposure to chemicals and biological agents. Laboratory requirements for safe exposure to chemicals are set forth in 10 CFR 851, DOE’s Worker Safety and Health Program rule. This regulation establishes safe work practices, necessary training, and allowable limits to help assure worker protection. One part of the requirements (10 CFR 851.21) specifies the need to identify and assess workplace hazards, including the potential for employee exposure. These assessments can be conducted using multiple methods, including representative air monitoring, estimation, or other modeling.

Exposure assessments shall be conducted in response to customer requests, as a followup to observations or concerns identified during development or reviews of WPC Activities or other planning efforts, in relation to technical program requirements or targeted evaluations, or in response to other concerns by customers or by EHS personnel.

Re-surveys (exposure assessments which evaluate a previously-assessed task or exposure event) shall be conducted when necessary to validate findings of prior surveys, or to determine if any changes in operations or site conditions have resulted in changes in exposures. Technical program requirements may define re-surveying requirements.

Assessments of tasks are often performed through a qualitative hazard assessment process. The tasks may include those which are regularly occurring and well understood. A hazard assessment of these types of tasks and operations is conducted to provide sufficient evaluation of the hazard itself and the workers’ potential for exposure. Hazard assessments are also used to support requirements of specific technical programs such as the Respiratory Protection Program.

Exposure and hazard assessments may be qualitative or quantitative:

- Baseline Exposure Assessments (BEAs) are performed to characterize the exposure potential for an operation or task, and to determine whether more in-depth assessment is appropriate. BEAs are usually qualitative. BEAs are typically conducted for well-understood tasks (such as the handling of chemicals of moderate or low toxicity inside fume hoods and with appropriate work practices), but are also performed during the work planning phase of new operations. Qualitative baseline exposure assessments are often performed to determine whether a more in-depth quantitative exposure assessment is warranted.

- Exposure Assessments may be qualitative or quantitative, and often focus on the potential exposure to one or a few chemical/biological agents. These assessments are usually conducted by Berkeley Lab industrial hygienists from the EHS Division and may be initiated via one or a combination of WPC Activities, employee requests, walkthroughs, or other means.

- Hazard Assessments may also be qualitative or quantitative. A preliminary evaluation (or screening) of an activity may be conducted to determine if a more comprehensive exposure assessment is required. Hazard assessments can be performed by work leads, supervisors, workers, or an EHS professional.

Similar Exposure Groups (SEGs) are used when possible to characterize exposures to groups of workers by identifying similar tasks and processes performed by the workers, and which involve the same set of agents. Findings of exposure assessments are reviewed to ensure that the assigned controls for operations are effective in maintaining exposures below applicable limits, as noted in Work Process C. Statistical analysis of the data, including the findings associated with SEGs, may be performed.

The Exposure Assessment Program is periodically evaluated for assurance purposes to assess the effectiveness of the program.

Work Process B. Exposure and Hazard Assessment Records

Exposure and hazard assessment records – whether qualitative or quantitative – are generally considered employee exposure records and therefore shall be retained for at least 75 years after termination of employment. Exposure and hazard assessment records produced by EHS Division are maintained in electronic form in the Comprehensive Health Environmental and Safety System (CHESS) application and/or in hard copy form.

Berkeley Lab workers have a right to records related to their exposure or medical status. This includes exposure and hazard assessments, results of medical surveillance, and other exposure-related information, such as safety data sheets.

Work Process C. Controlling Exposures

Line managers and workers must implement effective controls to control exposures to hazardous chemicals and physical agents to acceptable levels. Workers shall not be exposed to chemicals or physical agents at levels exceeding applicable Occupational Exposure Limits, such as Threshold Limit Values® (TLVs).

Controls to manage such exposures are typically assigned or described in WPC Activities for the work being performed. Exposure or hazard assessments may be requested, for example, by line managers and Activity Leads. The WP&C process accommodates direct requests for exposure or hazard assessments.

Prior to handling chemicals or other materials that might produce harmful exposures, or performing work involving potentially excessive exposures to noise, vibration, heat, or other physical agents, workers must complete applicable training that covers the hazards and the appropriate methods for controlling the hazards. Berkeley Lab training courses that address these hazards include EHS0345 Chemical Hygiene for Facilities, EHS0348 Chemical Hygiene and Safety, EHS0344 Safe Handling of Engineered Nanoscale Particulate Matter, EHS0356 Nano Safety for Crafts and Technical Work; and EHS0330, Lead Worker Training. In many instances, effective on-the-job training (OJT) will address the proper use of controls for the specific tasks. The application of hazard controls is also addressed in training courses, such as those for use in respiratory protection.

Hazard controls may include one or a combination of the following:

- Hazard Elimination, such as:

- Eliminating the agent

- Substituting the agent for one of less or no hazard

- Engineering Controls, such as:

- Shielding

- Ventilation

- Administrative Controls, such as warning signs and postings

- PPE, such as:

- Respiratory protection

- Protective gloves

4.8 Source Requirements

- 10 CF-R 851.21(a)(5) (2019), Worker Health and Safety Program; Hazard Identification and Assessment; Evaluate Operations, Procedures, and Facilities to Identify Workplace Hazards

- 29 CFR 1910.1020, Access to Employee Exposure and Medical Records

- 10 CFR 850 (1999), Chronic Beryllium Disease Prevention Program

4.9 Reference Documents

|

Document Number |

Title |

Type |

|---|---|---|

|

07.07.013.000 |

Exposure Assessment |

Program |

|

07.07.019.001 |

Lead Hazards and Controls |

Program |

|

07.07.002.001 |

Asbestos |

Program |

|

07.07.003.001 |

Beryllium |

Program |

|

07.07.016.001 |

Heat Stress |

Program |

|

07.07.023.001 |

Non-Ionizing Radiation |

Program |

Other References

- DOE Standard 6005, Industrial Hygiene Practices (guidance only)

- AIHA, A Strategy for Assessing and Managing Occupational Exposures, Fourth Edition, 2015 (guidance only)

- DOE Guide 440.1-8, Implementation Guide for Use with DOE Guide G 440.1: Occupational Exposure Assessment

- American Conference of Governmental Industrial Hygienists Threshold Limit Values ®(2016)

- Title 8 California Code of Regulations, Section 5155 Airborne Contaminants

_____________________