Contents

Approved by Michael Kincaid

Revised 5/21

27.1 Policy

27.2 Scope

27.3 Applicability

27.4 Roles and Responsibilities

27.5 Definitions

27.6 Required Work Processes

- Work Process A. General Requirements for Crane Operation

- Work Process B. Procurement and Maintenance of Cranes and Hoisting and Rigging Equipment

- Work Process C. Authorization and Qualification to Use Cranes

- Work Process D. Restricted Operations

- Work Process E. Mobile Cranes

- Work Process F. Crane Inspections

- Work Process G. Rigging and Other Below-the-Hook Devices and Fixtures

27.7 Standards

27.8 Related ESH Manual Chapters

27.9 References

Note:

🚩🚩 Denotes a new section

🚩 Denotes the beginning of changed text within a section

🛑 Denotes the end of changed text within a section

_________________

27.1 Policy

Persons involved in crane or hoist operations at Lawrence Berkeley National Laboratory (Berkeley Lab) must:

- Be aware of the hazards related to the equipment and the load

- Know the methods for controlling those hazards

- Follow the proper operating procedures applicable to the type of lift and equipment

The designated operator must be qualified and authorized to use specific equipment.

Crane, hoist, and rigging equipment must be procured through the Facilities Division or from a Berkeley Lab approved vendor, as well as properly inspected, tested, and maintained.

27.2 Scope

Berkeley Lab’s Crane Safety Program is implemented through planning, authorization, qualification, and the appropriate use of properly inspected and rated hoisting equipment and rigging. Lifting and moving loads with forklifts is covered in ESH Manual, Chapter 28, Forklifts and Other Powered Industrial Trucks. Construction operations involving cranes are covered in Chapter 10, Construction Safety.

27.3 Applicability

This policy establishes requirements for Berkeley Lab’s Crane, Hoisting, and Rigging Safety Program and applies to work with any crane or hoist operated at Laboratory-owned or -leased property, as well as Laboratory-managed field research. This program applies to the following Berkeley Lab personnel:

- Employees

- Affiliates

- Construction contractors

- Non-construction contractors and vendors

27.4 Roles and Responsibilities

|

Role |

Responsibility |

|

Supervisors and Work Leads |

|

|

Crane Manager A Berkeley Lab employee must be identified as the Crane Manager for each Berkeley Lab-owned crane or hoist, unless it is locked out. |

|

|

Employees (Operators, Riggers, and Helpers) |

|

|

Mechanical Engineering Designee |

|

|

Responsible Designer |

|

|

Customer Management |

|

|

Facilities Division Structural Engineering Group Designee |

|

|

Facilities Division Rigging Supervisor |

|

|

Facilities Division Crane Maintenance Vendor |

|

|

Facilities Division Maintenance Manager |

|

|

EHS Division Crane Safety SME |

|

|

|

The individual appointed by a Divisions line management and documented as such to be the Management Representative who, regardless of other duties, shall have established authority over and responsibility for classifying the following:

Note: Defer to DOE STD-1090-2020 for guidance on lifts. |

|

|

Individual who shall have the knowledge and experience of the specific type of equipment and assigned lifting operations. This person shall be present at the lift site during the entire lifting operation. If one person is making the lift, that person assumes all responsibilities of the lift director.

|

|

Procurement |

|

27.5 Definitions

|

Term |

Definition |

|

Crane |

A machine used for lifting and lowering a load vertically and moving it horizontally, and that has a hoisting mechanism |

|

Engineering Note |

A detailed description of a (fixture) design, or a detailed description of a high-consequence/high-value lift/move, including protection of the load, rigging, and method(s) of transport |

|

Ordinary Lifts |

Any non-critical/high consequence/high value or pre-engineered lift.

|

|

Pre-Engineered/Production lifts |

A repetitive lift that is performed by production line personnel in the assembly or disassembly of components or systems where detailed lift planning, equipment selection, and lift-specific training may substitute for the qualifications. Any engineered lifts shall be developed & approved via step by step procedures containing the following information:

Procedure Verification:

|

|

|

When standard operating, maintenance, inspection, or test procedures cannot be followed as a result of radiation or radioactive contamination, toxic/hazardous chemicals or gases, or temperature extremes or other hazards:

|

|

Procedure Training |

Specialized training shall be conducted for personnel involved in performance pre-engineered production lifts, with training oversight by responsible operating and oversight organizations. It shall cover at minimum:

|

|

Critical Lift/High-Consequence/High-Value Lift/Move |

|

|

Hoist |

A device that applies a force for lifting and lowering |

|

Lifting Device |

A device, other than a sling, used below the hoisting hook for attaching loads to a hoist. There are four types of lifting devices:

|

|

Lifting Fixture |

A fixture used below the hoisting hook designed and engineered for lifting a specific item |

|

Mobile Crane |

A crane system fixed to a vehicle, typically a truck |

|

Overhead Crane |

A crane system fixed to a structure, including but not limited to bridge cranes, monorail cranes, gantry cranes, and jib cranes |

|

Rigging |

|

27.6 Required Work Processes

Work Process A. General Requirements for Crane Operation

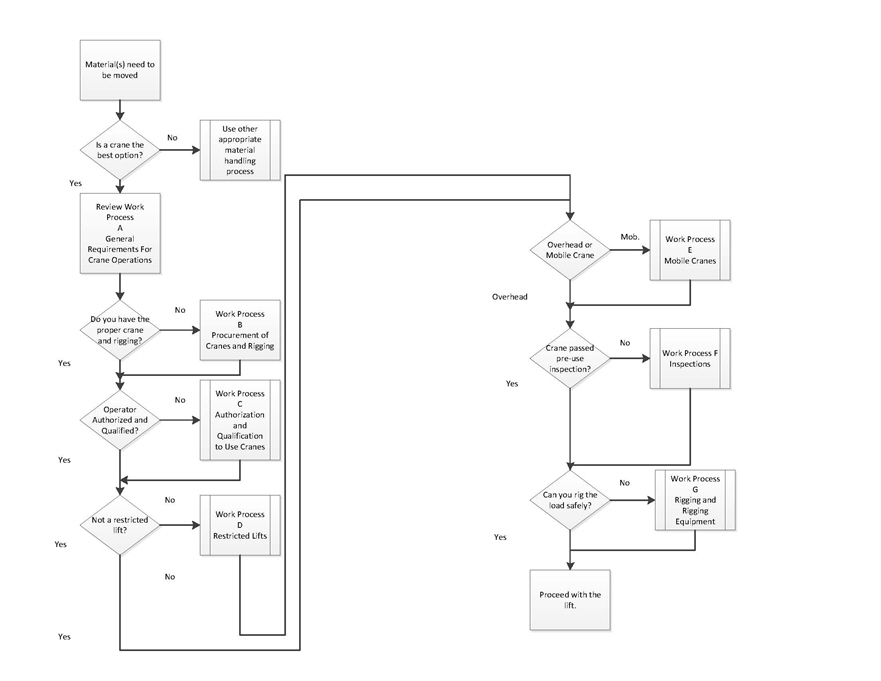

The work flowchart below provides a step-by-step overview of crane and hoist operations requirements (go here to download a PDF of the flowchart):

The following rules apply to all use of crane and hoist operations at Berkeley Lab.

- Whoever needs to move a load must:

- First determine the value of the load and consequences of a failed move

- Determine if the load needs to be moved by a crane

- Determine who can operate the crane

- Loads meeting the definition of Critical/High-Consequence/High-Value Lifts/Moves or other restricted operations (see Work Process D) require more detailed planning and may require the lift to be performed by the Facilities Division Riggers.

- Operators must be authorized by Line Management to use cranes.

- Operators must be authorized by the Crane Manager to use a specific crane.

- Operators must be qualified and authorized on the type of crane they intend to use.

- Operators must plan each lift, taking into account the path of travel to avoid contact with personnel and objects.

- Loads meeting the definition of Critical/High-Consequence/High-Value Lifts/Moves or other restricted operations (see Work Process B) require more detailed planning and may require the lift to be performed by the Facilities Division Riggers.

- Operators must inspect the crane and associated rigging prior to using the crane.

- Cranes and rigging found to be deficient must be taken out of service, and cannot be used unless repaired and recertified by the Facilities Division Crane Maintenance Vendor.

- Cranes and rigging must be rated to lift the intended load; no load (including rigging, devices, and lifting fixtures) may exceed the limits of the crane and rigging. If an employee is unsure of the weight of a load, or if the load weight exceeds 75% of the crane’s configured/set-up capacity (whether on tires or outriggers), contact the Facilities Division Rigging Supervisor for assistance. Crane testing by the Facilities Division Crane Service contractor is the only exception to this rule..

- Operators are responsible for ensuring that the load is properly rigged to avoid shifting during the lift. Test lifts of less than one foot from the ground to check for load shifting are permitted.

- For mobile telescopic and lattice boom cranes lifting operations must cease when the local weather forecast calls for thunder/lightning storms to be in the area.

- Refer to the manufacturer’s specifications for safe operations in windy conditions. If no specifications can be found and no licensed professional structural engineer is available to determine the safe working wind speed(s), then operations should cease if sustained gusts and/or winds of 25mph or greater occur. The nearest qualified weather reporting service should be referred to for wind speeds if the crane is not equipped with an anemometer. Contract the Facilities structural engineer if further assistance is needed.

- All personnel who are operating a crane or hoist, are participating in the lift, or are located within 15 feet of the vertical plane of the load — where the undercarriage of the bridge is more than 12 feet from the ground — must wear hard hats. Post or barricade the area as needed.

- Sturdy work gloves must be worn when handling wire rope or loads with rough or sharp edges or splinters.

Lift Planning and Procedures

Lift Planning and Procedures

- Lift planning should comply with ASME P30.1, “Planning for Load Handling Activities,” and shall comply with 48 CFR 970.5223-1, “Integration of Environment, Safety, and Health into Work Planning and Execution,” aka Integrated Safety Management System (ISMS). The following additions and exceptions to the above cited standard should also be implemented.

- A written lift plan beyond normal site work planning and control documents is not required for ordinary lifts. However, the Lift Director may determine that a written plan is prudent.

- The lift director shall ensure that in addition to the P30.1 “Standard Lift Plan” considerations, the following pre-lift planning issues are addressed, as applicable, prior to the lift:

- Identify the item(s) to be moved, its intrinsic characteristics (load integrity, loose materials, liquids) weight, dimensions, center of gravity and ability to support imposed lifting forces (both load and lift points), and whether it contains any hazardous or toxic materials.

- Validate the loads path and clearances.

- Identify lifting equipment and rigging to be used by type and rated capacity.

- Prepare rigging sketches as necessary

- Evaluate the work area for conditions impacting crane setup operations (weather soil bearing capacity, overhead or sub surface utilities (may be covered in Activity Hazard Analysis).

- Identify any special or site-specific operating procedures and special instruction.

- Some ordinary lifts have additional risks that warrant special consideration. Such lifts shall have documented plans but do not require the technical rigor of a critical lift and do not have to be performed in a step-by-step sequence. If sequential actions are required because of the complexity of the lift or operation then they must be noted in the lift plan. A written lift plan shall be created for lifts where any of the following conditions are present:

- Load transfer; such as transferring a load in mid-air from one lifting device to another

- Any load that its center of gravity might be relocated due to lifting operation; such as a tank filled with liquid

- Use of multiple lifting devices; such as the use of more than one piece lifting equipment in sharing the load (Ref. 29 CFR 1926.1432) ”Use of complicated custom designed rigging equipment or hardware”

- Working in or within the reach of the crane (the area 360 degrees around the crane equipment, up to the crane equipment’s maximum erected/fully extended boom length).

- The specified clearance of power lines per 29 CFR 1926.1407-1411 or ASME B30.5(2018).

- The limited approach boundary of exposed energized electrical equipment as defined per NFPA 70E.

- Multiple load line operation such as those referred to in 29 CFR 1926.1432

- Lifting Personnel.

Suspended Loads

These rules apply to operators of suspended loads:

- Test brakes under load

by slightly raising then lowering

the load a few inches and apply the brakes.

- Ensure loads are never lowered below the point where less than two full wraps of rope remain on the hoisting drum.

- Do not allow hoisting chains or ropes to kink or twist, or to wrap around the load.

- Attach the load to the load block hook ONLY by means of slings or other approved devices; NEVER wrap the hoist rope around the load.

- Ensure loads are well secured and properly balanced in the sling or lifting device before it is lifted more than a few inches.

- Avoid suddenly accelerating or decelerating the moving load.

- Do not allow the load to contact obstructions.

- Do not allow loads moved with any material-handling equipment to pass over any personnel.

- Select the load path to eliminate the possibility of injury to employees should the material-handling equipment fail.

- Do not permit work on suspended loads. Rest the load on adequate cribbing if it needs to be worked on.

- Never leave a suspended load unattended nor leave the controls while the load is suspended. Lower the load to the floor or the working surface or onto cribbing, and secure the material-handling equipment before leaving the load unattended.

Component Failure or Unintended Movement

If any component fails during a lift, or if there is any uncontrolled or unintended motion of the load during the lift, the lift must be terminated immediately in the safest manner possible. Immediately notify the Crane Manager of the component failure. Contact EHS and the Facilities Division Rigging Supervisor.

Lifting may only resume after the failure or unintended motion has been investigated, and appropriate corrective steps have been implemented.

Securing Cranes

Any electric-powered crane, when not attended by a qualified operator during an entire shift and off-hours, must be secured by locked controls or equivalent means to prevent access to the crane, such as locking the doors or locking up radio controls. Only the Crane Manager or another qualified and authorized user of the secured crane may have control of the locking mechanism.

Work Process B. Procurement and Maintenance of Cranes and Hoisting and Rigging Equipment

Approval from the Facilities Division Structural Engineer must be obtained before purchasing hoists or cranes that will be attached to any LBNL building or structure. Free-standing lifting equipment or cranes as well as rigging such as shackles, clevises, wire rope or fabric slings, or spreader bars (strongbacks) must be purchased from an LBNL-approved hoisting and rigging vendor. Use of the pre-approved vendors ensures that the required standards and certification requirements are met. The Facilities Rigging Superintendent or the EHS Crane Safety SME can provide assistance in selecting cranes and rigging equipment to meet specific needs or circumstance.

If used equipment is procured, it must be inspected and certified to meet all applicable standards in force at the time of the acquisition prior to use at LBNL.

For Berkeley Lab—designed and/or fabricated lifting devices, see Work Process G.

When equipment is received, the recipient must contact the Facilities Division Crane Maintenance Vendor (cranesafety@lbl.gov) to have the equipment inventoried for routine inspection and maintenance. Do not discard any certification papers received with the equipment. All hoisting and rigging equipment (except when impractical, e.g., shackles, swivel lifting rings, etc.) used at the Laboratory must have a Laboratory proof-load tag attached with a current inspection sticker. The user, supervisor, and operator are directly responsible for verifying the presence of current, proper tagging of hoisting and rigging equipment prior to use.

Work Process C. Authorization and Qualification to Use Cranes

All crane use must be authorized by an employee’s supervisor, through the Work Planning & Control (WPC) process, and by the Crane Manager for the particular crane(s) to be operated. The Crane Manager is a qualified crane operator who has been designated as the individual responsible for the safe operation of a specific crane. Before operating a crane in an area for the first time or in a new application, employees must discuss the proposed crane use with the Crane Manager and obtain approval. The Crane Manager will determine whether the operator is familiar with the controls for that particular crane and knows how to properly rig loads, and will verify that crane use will not conflict with other operations in the area.

Cranes may also be operated by qualified Crane Service personnel who have been authorized through the WPC process or an SWJHA (for the on-site Facilities Division Crane Maintenance Vendor), and have been subcontracted to install, maintain, or repair cranes.

Qualifications, Training, Certification, and Approval Requirements for Overhead Crane and Hoist Operators

The operation of overhead cranes and hoists is restricted to trained personnel who have completed Berkeley Lab—required training, and who have been certified in accordance with the requirements of this chapter. This includes the operation of cranes without a load for any reason. Requirements for operating mobile cranes can be found in Work Process F.

To become certified for operating cranes up to a two-ton capacity, the following requirements must be met:

- All prospective operators of cranes and hoists up to a two-ton capacity must meet the health requirements that would entitle them to operate a motor vehicle in the state of California. Individuals who do not hold a valid driver’s license must be examined and approved by Health Services at Berkeley Lab.

- The prospective operator must complete EHS0210, Crane/Hoist Operator — 2 Tons or Less. This course includes hands-on instruction. A record of training will be made with the EHS training department after the successful completion of the course.

Note that crane and hoist operators authorized for less than two-ton cranes may NOT operate cranes or hoists with a capacity of greater than two tons to lift loads of less than two tons or without any load.

To operate overhead cranes or hoists with a capacity of greater than two tons, the following is required:

- All prospective crane operators must complete an application and must pass a medical examination and/or review of medical information on file at Health Services prior to training. The application must identify a qualified crane operator who will provide hands-on instruction and close supervision during an initial training period. The supervisor and the operator who will provide the instruction must sign the application and agree to the initial training. If the prospective operator has prior experience operating cranes, he or she may be examined and authorized without an initial training period.

- The prospective operator must complete EHS0206 (Crane/Hoist Operator — Greater than 2 Tons). Upon completion of this classroom training, the individual may only operate cranes and hoists they have been authorized to use per the crane manager under the direct supervision of the operator identified on the application, until such time the prospective operator is identified as qualified for the practical examination.

- When the prospective operator is ready, they may contact an overhead-crane practical-examination instructor to be examined on the operation of the specific crane to be operated most frequently. A list of qualified overhead-crane practical-examination instructors is maintained by the EHS Division Training Group.

Crane operators must renew their training every three years, and must be medically recertified every three years.

Work Process D. Restricted Operations

Critical/High-Consequence/High-Value Lifts and Moves

A management representative shall classify the lift as critical prior to planning the lift when the following applies:

- Cause damage in excess of $500,000

- This requirement does not apply to routine movements of shielding blocks performed by members of the professional rigging crew.

- Cause significant work delay or programmatic impact

The cost to replace or repair the load item, or the delay in operations of having the load item damaged would have a negative impact on facility, organizational, or DOE budgets to the extent that it would affect program commitments.

The load item is unique, if damaged, would be irreplaceable or not repairable and is vital to a system, facility or project operation.

- Cause undetectable damage resulting in future operational or safety problems

The load item if damaged or upset would result in a release into the environment of radioactive or hazardous material.

- Present a potentially unacceptable risk of personnel injury or property damage

- Any lift that exceeds 75% of the configured crane configuration/setup (for mobile, telescopic, and lattice boom cranes.

- In addition, any lift/move that requires the simultaneous use of both the main and auxiliary hoists of a given crane or the simultaneous use of two cranes must be considered a critical/high-consequence/high-value lift/move.

Critical/High-Consequence/High-Value Lift/Move Requirements

A detailed, step-by-step procedure in the form of an Engineering Note must be prepared for each critical/high-consequence/high-value lift/move. This requirement covers lifts and moves performed with forklifts or cranes. An Engineering Note template may be obtained from the Engineering Division through submitting a work request at https://workrequest.lbl.gov/jsp/workreq_add.jsp. While high-consequence/high-value lift procedures are customarily prepared for one-time use, general critical/high-consequence/high-value lift procedures may be employed to accomplish routine, recurrent high-consequence/high-value lift operations. For example, a general critical/high-consequence/high-value lift procedure may be applied to lift shielding blocks or a frequently lifted items. Examples can be found through the search page of the Berkeley Lab Engineering Note Repository at http://engineering.lbl.gov/employee-resources/. (Select “Document Control Center” – logging in using your LDAP as necessary – then enter the keywords “high value” in the Category 4 Title 3 field).

The customer, i.e., the Laboratory manager who requires the item to be moved, is responsible for preparing the critical/high-consequence/high-value lift/move Safety Engineering Note. The customer can discharge this responsibility by indicating on the Facilities or Engineering Division Work Request that the scope of work should include preparation of the Engineering Safety Note and management of the move. It is the responsibility of the customer to notify all personnel whose review is required early in the process. See Critical/High-Consequence/High-Value Move Lift/Move Approval below.

Reviewers have special expertise and are available to provide guidance during the design of the lifting procedure. Please allow sufficient time for the review-and-approval process. There is no charge for the review-and-approval process.

The procedure must contain the following:

- Identification of the item to be moved

- Identification of the Laboratory manager or engineer who is responsible for planning the lift

- Identification of the rigging supervisor or designated qualified rigger (other than the equipment operator) who will be the Person In Charge (PIC) of all aspects of the lift while the load is suspended

- Special precautions

- Weight of the item

- Total hook load (all component parts of the item plus tackle and load-measuring devices)

- Determination of the center of gravity

- A list of each piece of equipment and each accessory (e.g., slings, spreader bars, yokes) to be used in the lift

- Each accessory must be identified by type and rated capacity

- If a portable item to be used has no manufacturer’s serial number, a Berkeley Lab identification number must be assigned and affixed to the item

- Surveillance procedures, checkpoints, and estimated instrument readings (if used) must be listed to enable confirmation that the lift is proceeding as planned

- Calculation of stresses to be generated in the item during lifting and determination of the adequacy and proper labeling of the attachment points of the item to be lifted.

- A rigging sketch or sketches that include the following:

- Lifting points

- Load vectors at all stages of the lift/move

- Sling angles at all stages of the lift/move

- Accessories used

- Method(s) of attachment

- Method of rotating about either horizontal axis, if applicable

- Other factors affecting the capacity of the equipment or accessories

- Identification of the capacity (or limit) of equipment and load

- Identification of the expected load in each item of equipment and each accessory

- A load-path sketch of the load path with the expected height of the load at each point in the lift

- Where appropriate, floor loading diagrams are to be included to provide for setting the load down at any point in the path if that should be necessary.

- A travel sketch, either as a part of the load-path sketch or a separate sketch, indicating the planned travel path, and lifting and travel speeds

- Where clearances are an issue, a detailed drawing with verified dimensions that demonstrates the lift can be accomplished as planned

- An assessment of wind loading and weather concerns for all outdoor work

- Obtain assistance from the Facilities Division Structural Engineering Group for wind loading concerns.

- A checklist detailing each step of the procedure, with each step initialed by the Laboratory manager or engineer responsible for the planning of the lift

- A sign-off sheet where all personnel involved in the lift verify that they are familiar with the contents of the procedure

- Load tests and practice lifts, if required

- Verification that all primary and secondary hoisting equipment is within the current inspection and test time requirements as specified in this chapter (for example, yearly periodic inspections and certification)

Critical/High-Consequence/High-Value Lift/Move Approval

The procedure must be reviewed by:

- Customer management

- The Engineering Division Mechanical Engineering Department Designee

- The assigned Facilities Division Structural Engineer

- The Facilities Division Rigging Supervisor

- The EHS Division Designee

The procedure must be approved by the appropriate engineer:

- For lifts/moves using overhead building cranes, the Engineering Division Mechanical Engineering Department Designee is the approver.

- For lifts/moves using mobile cranes, forklifts, or jack and roll devices, the assigned Facilities Division Structural Engineer is the approver.

All reviewers and approvers should be consulted early in the process to ensure their concerns are addressed, avoiding the need for later revisions to the procedure.

Unanticipated conditions may require on-the-spot changes of the lift procedure. Approvers of the lift procedure should be present during the lift or at least immediately available to approve changes. Changes must be recorded on the procedure and initialed by all available approvers before they are implemented.

Personnel Participating in Critical/High-Consequence/High-Value Lifts/Moves

Each person involved in a critical/high-consequence/high-value lift/move must be familiar with the procedure before beginning work. A pre-lift meeting with all participating personnel must be held before the lift. All participating personnel must initial the procedure sign-off sheet to verify that they are familiar with the procedure.

Cab-Operated Cranes

Operation of cranes from a cab is restricted to professional riggers. The following rules apply to cab-operated cranes:

- Do not store personal belongings (including necessary clothing) in a manner that interferes with operations.

- Store other necessary equipment (tools, oil cans, waste, extra fuses, etc.) in the toolbox. Do not store equipment loosely in or about the cab.

Heavy Lifts

Heavy lifts should be made by the professional rigging crew that performs such work routinely. Where there is a need for other personnel to lift loads over 10,000 lb., the proposed lift must be reviewed with and approved informally by the supervisor of the professional rigging crew or his or her designee.

Tilting Loads

Using a crane to tilt a load (standing up a load that is lying down or vice versa) carries a significant risk of shock-loading the crane or losing control of the load. When such operations involve loads that exceed 50% of the rated capacity of the crane, they must be reviewed by and may be performed only with the informal approval of the supervisor of the professional rigging crew or his or her designee. If two hooks are required to tilt the load, follow the critical/high-consequence/high-value lift procedures listed above.

Work Process E. Mobile Cranes

The operation of mobile cranes is restricted to those who have been certified as competent and qualified mobile crane operators by an independent certification agency. The Facilities Division Riggers have authorized and qualified mobile crane operators.

Mobile crane operations for construction have additional requirements, which are found in Chapter 10 Construction Safety. For the purpose of the Berkeley Lab Cranes, Hoisting, and Rigging Program, small truck-mounted jib cranes with capacities of less than 2 tons are not considered mobile cranes. Mobile crane operations are conducted in accordance with all applicable Occupational Safety and Health Administration (OSHA) (and Cal/OSHA for construction) requirements.

Any mobile crane, when not attended by a qualified operator during an entire shift or during off-hours, must be secured by locked controls or equivalent means to prevent access to the crane, such as locking the doors or locking up radio controls. Only the Crane Manager or another qualified and authorized user of the secured crane may have control of the locking mechanism.

Work Process F. Crane Inspections

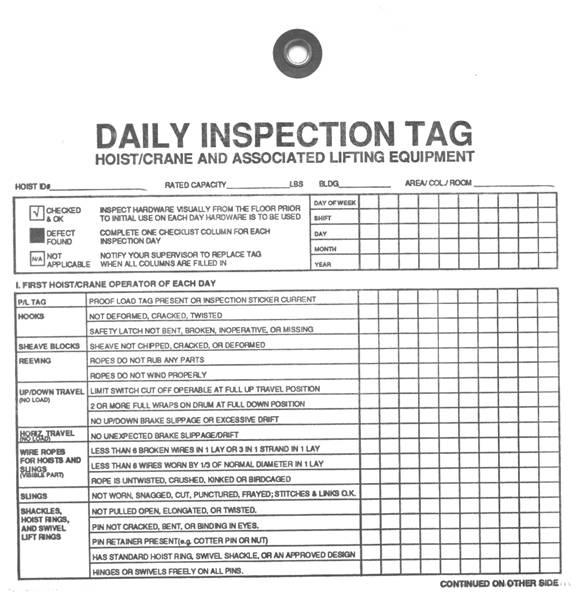

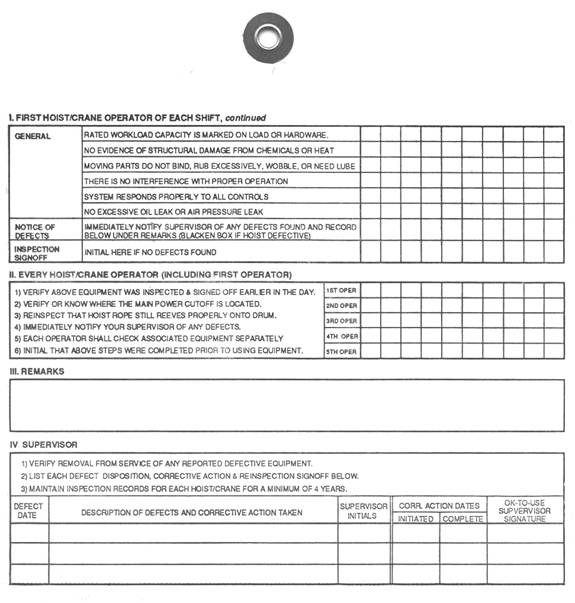

Each crane or hoist must be inspected by a qualified crane operator before use, during any given work shift. The inspection can be documented either on a tag attached to the crane controls or in a log that is kept with the key to the crane controls. If the crane is not used during any shift, it does not need to be inspected. Cranes used infrequently (idle for one to six months) may be inspected by a qualified operator as a before-use inspection. However, if a crane has been idle for more than six months, the Facilities Division Crane and Hoist Services Contractor must perform a periodic inspection before it may be used. Where applicable, crane inspection logs will be reviewed by the Crane and Hoist Services Contractor. Typical crane inspection checklists are shown in Appendix A of this ES&H Manual chapter.

All other required equipment inspections (including periodic crane and hoist inspections) and tests are performed by the Facilities Division Crane and Hoist Services Contractor. Equipment and the frequency of equipment inspections and tests are listed in a Facilities Division database as required by applicable regulations and/or standards. Facilities Division Crane and Hoist Services Contractor work orders are automatically generated monthly and are based on information in the database.

Work Process G. Rigging and Other Below-the-Hook Devices and Fixtures

The crane operator is responsible for verifying that the load is properly rigged. The crane operator must also take the following precautions when performing work:

- Thoroughly inspect rigging before use (document the inspection on the Daily Crane Inspection Tag).

- Remove defective rigging from service. DO NOT USE and DO NOT REPAIR defective rigging.

- All other required rigging inspections and tests are performed by the Facilities Division Crane and Hoist Services Contractor. The frequency of these various inspections and tests are detailed in Facilities Division work orders.

- Only use slings in accordance with the manufacturer’s recommendations and ASME 30.9 Slings & ASME B30.26 Rigging Hardware.

- All manufactured lifting/hoisting points on equipment received by LBNL should at minimum be visually inspected prior to hoisting to confirm they are free from damage which could have occurred during shipping.

- Additional sling protectors (a.k.a. softeners) must be used in all situations where slings may, can, or do come into contact with non-rounded or sharp edges.

- All rigging and sling protection must be engineered and qualified equipment, used in accordance with manufacturer guidelines and in accordance with DOE EHSS OE 3:2018-03 Engineered Sling Protection, and DOE RPP-RPT-42583, Rev 0 guidance.

- Use engineered attachment points and standard hardware (swivel lift rings, shackles, and nylon slings) wherever possible.

- Verify that all slings and hardware are rated for more than the expected load and are appropriate for the intended type of load and configuration.

- Verify that all slings and special lifting hardware have current Berkeley Lab inspection tags.

- Never shorten slings with knots, bolts, or other makeshift devices.

- Never load rigging in excess of its rated capacities.

- Verify loads are balanced to prevent slippage (e.g., when using a basket hitch).

- Remove slings from a load when the load is not resting on the sling.

- Contact the EHS Crane and Hoist Subject Matter Expert (cranesafety@lbl.gov) or the Facilities Division Crane Maintenance Vendor (ext. 7667) before rigging is used in any manner or environment (e.g., used in close proximity with corrosives or degrading chemicals, operated in temperature extremes of –20°F or +180°F, etc.) that may compromise its construction or strength.

- For rigging references, refer to “Rigging Handbook: The Complete Illustrated Field Reference,” by Jerry Klinke 5th Edition, June 2019, or an equivalent rigging manual.

- For rigging assistance contact the crane manager, or facilities rigging supervisor.

Inspection and Testing of Lifting Devices

Each division is responsible for the safety and pre-use inspection of its lifting devices (such as screw pin shackles, hoist rings, commercial equipment, etc.) and for its lifting fixtures (such as spreader bars, special slings, equipment designed at Berkeley Lab, etc.). Berkeley Lab proof-load tags and inspection stickers must be current, where applicable. Special-purpose lifting fixtures must be marked with a Laboratory equipment number and labeled to identify applicable Engineering Safety Notes for fixture design and/or critical/high-consequence/high-value lifts/moves.

All lifting fixtures designed at the Laboratory must be proof-tested to twice their maximum rated loads before being placed in service. A Non-Destructive Examination (NDE) is required after the proof test. The exact type of NDE must be specified in the Engineering Safety Note for the lifting fixture. The rated capacity must be marked on the lifting fixture so that it is clearly visible to the equipment operator.

Order commercially available lifting fixtures through the pre-approved hoist and rigging vendor or the Facilities Division Maintenance Manager or Designee to assure they are ordered with a certificate of proof load testing. For commercial lifting fixtures without certified load ratings, an Engineering Safety Note must be written to determine the safe load capacity and furnish guidance for load testing.

Where the lifting fixture cannot be proof-tested because it is an integral part or component of the experimental device, equivalent alternative safety precautions acceptable to the Mechanical Engineering designee must be described in the Engineering Safety Note, which delineates the lift procedure.

All lifting device pins of 5 cm (2 in.) in diameter or larger must have a magnetic-particle inspection before they are placed in service. These pins are always part of a lifting device or fixture. Make arrangements with the Facilities Division Crane Maintenance Vendor or the Work Request Center, ext. 6274, to have lifting fixtures inspected.

Active lifting devices and fixtures must be examined by an NDE at least once every four years (or upon request), using magnetic-particle detection or other appropriate methods. Make arrangements to have lifting fixtures inspected with the Facilities Division Crane Maintenance Vendor or contact the Work Request Center, ext. 6274. Records must be maintained by the Facilities Division and NDE organizations. Inactive lifting devices and fixtures must be clearly marked “STOP: DO NOT USE,” and must be load tested and certified prior to renewed use.

The Responsible User must ensure that:

- Proof-testing is performed by the Facilities Division on all lifting fixtures designed at the Laboratory, before they are placed in service

- Adequate test records are kept

- Lifting devices and fixtures are used and maintained correctly

The Responsible Designer must obtain design approval by means of an Engineering Safety Note, as described below. For equipment designed at the Laboratory, the Responsible Designer must provide the user with the information required to operate the lifting device or fixture safely. The Facilities Division will provide a test report to the user upon request.

Design of Lifting Fixtures

A qualified engineer must be designated to be responsible for the design, fabrication, and testing of lifting fixtures not purchased commercially. The actual physical testing usually will be performed by the Facilities Division in accordance with the written test procedure specified by the Project Engineer.

All lifting fixtures not procured through the Facilities Division, a Berkeley Lab approved vendor, or provided by the equipment (to be hoisted) manufacturer with proper engineering documentation must be covered by an Engineering Safety Note. The Engineering Safety Note must include the calculation of lifting fixture stresses and deflections, and must be reviewed by:

- The Responsible Designer

- Customer Management

- The Engineering Division Mechanical Engineering Department designee

- The Facilities Division Plant Operations Department Rigging Supervisor

- The EHS Division designee

The Engineering Safety Note must be approved by:

- The Engineering Division Mechanical Engineering Department designee.

The design stress for lifting fixtures or lifting attachment points must not exceed one-fifth the ultimate strength of the material at its operating temperature. If welded fabrication is used, the design stress must take into consideration any weakening effects of welding, such as those that occur in aluminum alloys.

If practical, avoid welding in the fabrication of lifting fixtures. If welding must be used, design and fabrication in conformance with the latest standards of the American Welding Society (AWS) are required. Careful, thoughtful design and follow-up are required.

Follow these rules for all lifting fixtures:

- All welds in lifting fixtures must be certified welds, performed by certified welders, and inspected and certified by certified weld inspectors.

- If at all possible, do not allow welds to be subjected to tearing loads. Stresses in welds must be substantially uniform.

- Where possible, design lifting fixtures so that the main loads are carried only by structural members, plates, or shear pins rather than by welds. Examine this possibility carefully.

- Proof-test lifting fixtures to twice the maximum rated load. Follow by a nondestructive examination. X-ray primary load-carrying welds and welds in tension, or perform other suitable subsurface crack-detection examinations.

- The screw-thread engagement required for conservative development of the full strength of a screw fastener depends upon the screw-fastener material and the material of the threaded member.

- If the fastener is made of the same material as the female threaded member — e.g., a low-carbon steel bolt and a hole threaded into low-carbon steel — an engagement of at least 1½ diameters is required.

- A hardened steel screw (Allen screw) in mild steel requires at least 2 diameters of engagement.

- A low-carbon screw fastener, threaded into a tapped hole in aluminum alloy, copper, or cast iron must have a threaded engagement of 1½ diameters.

- Other material combinations must be approved by the Mechanical Engineering Department designee.

- Safety hoist rings may be used to make lifts up to their rated load when screwed 2 hoist-ring bolt diameters into materials such as aluminum alloy, copper, or cast iron.

- When special high-strength bolts are required, test any bolt used as part of Laboratory-designed lifting fixtures or pickup devices to two times its rated load. A crack-detection inspection must be performed after the load test to ensure integrity. Try to maintain a supply of tested bolts in the event that one is lost, or better yet, to have the bolt on a permanent lanyard. Once a lifting device or fixture has been delivered to the user, the user is responsible for ensuring that the proper bolt is inserted to the proper depth and correctly torqued.

- When the lifting fixture also serves as a shipping container or frame holding the experimental device during transport, specify tie-down requirements and other special shipping requirements to ensure the integrity of the experimental device, e.g., anticipate flexing of the truck bed, acceleration due to bumps and potholes, and/or vibration.

- Label lifting attachment points adequately to ensure proper and safe use of the fixture.

Any deviation from these rules requires equivalent alternative safety measures that have been explicitly approved by the Mechanical Engineering Department designee.

Single-Bolt Pickup Devices

When equipment is designed to be crane-lifted at a single point with a single-bolt pickup device, the vertical lifting load through the screw thread of the bolt must be in line with the axis of the bolt so the load will remain level when it is lifted. With this bolt alignment, the lift will be through the center of gravity and will be safer, since the load will not tilt or kick out when it is lifted. A single-bolt pickup device must be used, such as a safety hoist ring or an equivalent in-house device that is carefully designed and maintained. The threaded engagement must comply with the requirements in the Design of Lifting Fixtures section, above.

When a load is to be crane-lifted by slings from a crane hook through two, three, or four pickup points located at the corners of the load, and without the use of a spreader bar, the forces at the lift points are non-vertical. Again, a single-bolt pickup device, such as a safety hoist ring or an equivalent in-house device that is carefully designed and maintained must be used at each pickup point.

Eyebolts without shoulders are not allowed for use in lifting any load. Eyebolts with shoulders are permitted for lifting loads when the following conditions are met:

- These devices shall be rated for the load and approved for the application, e.g., a carbon steel eyebolt rated at 1,500 lb. Threaded into a carbon steel block.

- The load is in line with the axis of the eyebolt, and side loads are minimal (a spreader bar may be required).

- The thread engagement is at least 2 bolt diameters. The eyebolts are torqued to a manufacturer’s recommendations, if given, or another reasonable torque substantially greater than finger tight. Angled sling usage is allowable if a manufacturer’s recommendations for load reduction are given.

The use of unrated eyebolts or eyebolts in applications not specifically approved by the manufacturer must be specifically approved by an Engineering Safety Note.

27.7 Standards

California Code of Regulations, Title 8, Subchapter 4, Construction Safety Orders (as it pertains to cranes used in construction work):

- 4884 Scope

- 4885 Definitions

- 4886-4913 Cranes (Except Boom Type-Mobile Cranes)

- 4920-4944 Boom –Type Mobile Cranes

- 4945-4956 Hydraulic Cranes and Excavators

- 4960-4964 Derricks

- 4965-4969 Tower Cranes

- 4970-4987 Hoists, Auxiliary Hoisting Equipment and Hoisting Operations

- 4990-5009 Operating Rules

- 5020-5028 Testing

- 5031-5035 Inspection and Maintenance

- 5040-5049 Slings

27.8 Related ES&H Manual Chapters

- Chapter 24 EHS Training Program

- Chapter 10 Construction Safety

27.9 References

- ASME HST-1M, Performance Standard for Electric Chain Hoists

- ASME HST-2M, Performance Standard for Hand Chain Manually Operated Chain Hoists

- ASME HST-3M, Performance Standard for Manual Lever Operated Chain Hoists

- ASME HST-4M, Performance Standard for Electric Overhead Wire Rope Hoists

- ASME HST-5M, Performance Standard for Air Chain Hoists

- ASME HST-6M, Performance Standard for Air Wire Rope Hoists

- Crane Manufacturers Association of America, Inc. (CMAA) Specification No. 61, Electric Overhead Traveling (EOT) Cranes

- ASME B30.26-2015, Rigging Hardware

- ASME B30.9-2014 Slings

- CMAA Specification No. 70, Specifications for Top Riding Bridge and Gantry Type Multiple Girder Electric Overhead Traveling Cranes

- CMAA Specification No. 74, Specification for Top Running and Under Running Single Girder Electric Traveling Cranes Utilizing Under Running Trolley Hoists

- DOE-STD-1090-2020, Hoisting & Rigging

- DOE EHSS OE 3:2018-03 Engineered Sling Protection

- DOE RPP-RPT-42583, Rev.0 Synthetic Sling Failure – Evaluations and Recommendations.

Appendix A. Typical Pre-use Inspection Tab

______________________________