Return to Chapter 45 Chemical Hygiene and Safety Plan.

DRAFT

Contents

Approved by Evelyn Davies

Revised 5/2025

Work Process A. General Requirements

Work Process B. Chemical and Equipment Procurement

Work Process C. Transporting Hazardous Materials

Work Process D. Berkeley Lab Chemical Inventory

Work Process E. Chemical Hazard Evaluation: Identification, Classification, and Categorization

Work Process F. Use and Application of Chemical Hazard Assessments

Work Process G. General Controls for Hazardous Chemicals

Work Process H. Selection and Use of Engineering Controls

Work Process I. Personal Protective Equipment

Work Process J. Work Practice Controls

Work Process K. Chemical Storage

Work Process L. Specific Controls and Procedures — Acids and Bases

Work Process M. Specific Controls and Procedures — Particularly Hazardous Substances: Carcinogens, Reproductive Toxins, and Acute Toxins

Work Process N. Specific Controls and Procedures — Flammables and Combustible Liquids

Work Process O. Specific Controls and Procedures — Laser Dyes and Solvents

Work Process P. Specific Controls and Procedures — Peroxide-Forming Compounds

Work Process P.1 Specific Controls and Procedures — Additional Time-Sensitive Chemicals

Work Process Q. Specific Controls and Procedures — Water-Reactive Chemicals

Work Process R. Specific Controls and Procedures — Pyrophoric Materials

Work Process R.1 Specific Controls and Procedures — Chemical Synthesis

Work Process S. Specific Controls and Procedures — Engineered Nanomaterials

Work Process T. Specific Controls and Procedures — Chemicals with Explosive Properties

Work Process U. Decommissioning or Transferring Equipment, Buildings, Laboratories, and Shop Spaces

Work Process V. Emergency Procedures and Equipment

Work Process W. Training

Work Process X. Safety Data Sheets

Work Process Y. Container Labeling

Work Process Z. Hazard Communication Requirements for Chemicals Produced in LBNL Laboratories

Work Process AA. Posting Area Entrances

Work Process BB. Designated Areas

Work Process CC. Exposure Assessments, Monitoring, and Medical Consultation

Work Process A. General Requirements

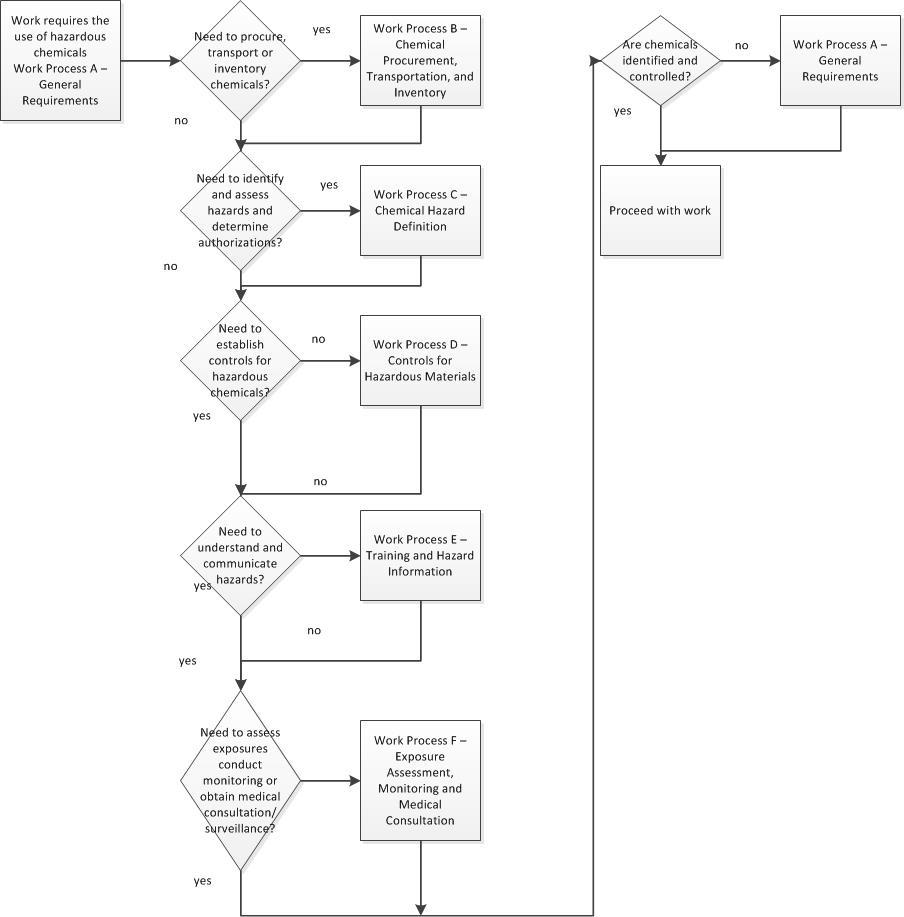

- Chemical Safety Work Process Flowchart

- Employee Rights. All personnel have the right to:

- Be notified of measured or suspected exposures to harmful substances at or above occupational exposure limits

- Request medical consultations and access their workplace medical and exposure records, and for their physician or collective bargaining agent to receive information regarding hazardous chemicals to which the employee may be exposed

- Refuse to work in unsafe conditions or to perform work that could create a hazard to themselves or other workers

- Protection against discharge or other discrimination due to exercising the rights afforded pursuant to the provisions of the Hazardous Substances Information and Training Act

- File confidential health and safety complaints with the UC Whistle blower Hotline at (800) 403-4744

Work Process B. Chemical and Equipment Procurement

- General Information. LBNL expects individuals to understand the risks of hazardous chemicals they purchase or allow onsite and to minimize the risks of those chemicals through elimination, substitution, reduction, use of engineering/administrative controls, and use of personal protective equipment where necessary. Pre-Procurement Assessment Requirements for Hazardous Chemicals in Section 2 must be met for all chemicals to be allowed onsite. All hazardous materials require screening and approval prior to arrival on-site. Screening and approval requirements for hazardous chemicals are determined by the acquisition route outlined in Section 3.

In addition, some chemicals and equipment have inherent safety hazards that require special safety controls and authorizations. It is important that these controls are in place before the material is procured and used on site. Materials of concern are listed in the Restricted Items List that is maintained by the Procurement Department in consultation with EHS (Section 4). None of the items on this list may be purchased using credit cards such as Division PCards or corporate credit cards. Section 4 also includes the list of chemical hazard categories that are considered “high hazard chemicals” per Work Planning and Control (high risk, Risk Level 3), and require an approved Work Activity prior to acquisition.

- Pre-procurement Assessment Requirements for Hazardous Chemicals

- LBNL expects individuals making the decision to allow a hazardous chemical onsite to do the following:

- Plan the work that requires the hazardous chemical (or notify the Activity Lead responsible for planning the work of hazardous chemicals that will be used)

- Have a plan for the disposal of hazardous waste

- Prepare for the safe use and storage of the hazardous chemical

- Ensure facilities are adequate, necessary safety controls are implemented, and individuals using chemicals are qualified

- Know if hazardous chemicals are on the restricted items list and obtain institutional approval for the use of those chemicals including chemicals brought onsite by other institutions (Section 3)

- Borrow what you need when possible

- Use less hazardous chemicals when possible

- Purchase only what is needed for the short term or project; plan for minimum waste and leftover unused hazardous chemicals

- Start using last of existing stock before buying new supplies (do not stockpile)

- The SDS should be reviewed prior to using hazardous chemicals. Refer to Work Process E for assessing chemical hazards. An EHS Health and Safety Representative may also be consulted for guidance.

- Some equipment contains chemicals that can pose a hazard when mishandled, such as elemental mercury in porosimetry (instruments for characterizing a material’s porosity by applying various levels of pressure to a sample immersed in mercury). When normal operation or reasonably foreseeable mishandling of chemical-containing equipment may result in a loss of control (such as a spill) that could pose an exposure hazard, cause extensive area contamination, or result in environmental damage, the Activity Lead must assess the hazards and implement controls. An EHS Division subject matter expert may be consulted. Moreover the Work Planning and Control (WPC) Activity for the work using the equipment shall address its off-normal consequences/hazards and the associated controls.

- LBNL expects individuals making the decision to allow a hazardous chemical onsite to do the following:

- Screening and Approval Requirements (Chemical Acquisition Resources)

- The acquisition of hazardous chemicals (including all compressed and liquefied gas cylinders) is subject to a hazard-based screening and approval process prior to arrival on site. Chemicals that meet the screening criteria and require further approval from EHS and/or Security and Emergency Services (including the Fire Protection Group) will be routed to the appropriate parties for approval based on the hazard, quantity, and location.

- For chemicals ordered through LBNL’s Financial Management System (FMS), including eBuy and ePro, the hazardous chemical procurement decision maker (e.g., Requestor) must indicate whether each requisition line item being ordered is a hazardous chemical or compressed or liquified gas by answering YES then entering the required information. Answering YES will automatically create an inventory record in CMS and information will be sent for screening and approval in CMS prior to the order proceeding.

- For hazardous chemicals (including compressed or liquified gas cylinders) that require CMS tracking to be acquired outside of FMS, including, but not limited to, primary manufacturer containers from collaborators or those acquired through a non-LBNL purchasing system and transported to LBNL, the Requestor must ensure these chemicals are added directly in CMS and approved prior to arrival on site (i.e. prior to ordering). Chemicals must be added in CMS with “ordered” status and will be routed for the same screening and approval process as for chemicals ordered in FMS.

- If a chemical to be acquired does not require CMS tracking (e.g. research samples), the Requestor is responsible for assuring the scope of work, including hazards, controls, and material quantities are covered by an authorized Work Activity.

- In any case, the Requestor is accountable for obtaining necessary approvals prior to arrival onsite, including approvals for materials falling under the Physical Security Program’s hazardous materials management policy and the Procurement Restricted Items List (see Section 4 below). Approval is facilitated by EHS and will be contingent upon verification that a Work Planning and Control Activity authorizing the scope of work is current and adequate facilities and controls are in place.

- The acquisition of hazardous chemicals (including all compressed and liquefied gas cylinders) is subject to a hazard-based screening and approval process prior to arrival on site. Chemicals that meet the screening criteria and require further approval from EHS and/or Security and Emergency Services (including the Fire Protection Group) will be routed to the appropriate parties for approval based on the hazard, quantity, and location.

- Restricted Items List and High Risk Chemical Hazard Categories

- The Restricted Items List includes chemicals and equipment, such as:

- Biological agent

- Biosafety cabinets

- Chemicals and gases (CHEMR):

- lethal/incapacitating toxicants and relevant precursors

- hazardous and reactive gases

- explosive and potentially explosive materials

- alkali metals

- select water-reactive chemicals

- pyrophoric liquids and solids (GHS)

- beryllium and beryllium-containing compound

- unstable and reactive materials

- Cal/OSHA regulated carcinogens

- peroxide-forming chemicals: Group A (may form explosive peroxides without concentration – test every 3 months)

- refrigerants and ozone-depleting substances (sulfur hexafluorixde – SF6)

- Chemical storage cabinets

- Fire extinguishers

- Fume hoods

- Gas storage cabinets

- Hazardous and toxic gases

- Laminar airflow hoods

- Laser equipment (excluding laser pointers)

- Radioactive isotopes

- Refrigerators and freezers for flammable liquid storage

- Respiratory protection equipment

- X-ray equipment

- Refer to the Restricted Items List for the Point of Contact (POC) for specific materials and equipment.

- High Risk Chemical Hazard Categories per Work Planning and Control (i.e. high hazard chemicals, Risk Level 3) have the highest degree of hazard, in which a loss of control could result in immediate injury or death, and therefore require a higher level of control and authorization. Risk Level 3 Chemical Hazards include:

- Corrosive, pyrophoric and toxic gases (See also Chapter 13)

- Explosives (primary and secondary)

- High acute toxicity chemicals (GHS Acute Toxicity Category 1 and NFPA Health Hazard Rating 4)

- Hydrofluoric acid and hydrofluoric acid-generating/releasing materials (such as hydrogen fluoride pyridine and buffered oxide etchant)

- Pyrophoric liquids and solids

- Tetramethylammonium hydroxide (TMAH) and solutions, etchants, and developers containing greater than 1% TMAH

- Water reactives (GHS substances or mixtures which, in contact with water, emit flammable gases, category 1, including alkali metals)

- See Work Process F. for examples of specific materials of concern.

- Refer to Work Planning and Control Activity Manager for applicable controls and additional information.

- Both CHEMR and high hazard chemicals (on a hazard-screening basis) require approval to verify that pre-acquisition requirements in Section 2 were met. As such, the Requestor should include the applicable WPC Activity ID during acquisition (Section 3) as required information to avoid delays.

- The Restricted Items List includes chemicals and equipment, such as:

Work Process C. Transporting Hazardous Materials

- Transporters

- Hazardous materials will be transported by Transportation Services or a Department of Transportation (DOT) authorized carrier (except as outlined below). Transporting hazardous materials via public transportation (such as the shuttle bus) or in private or government vehicles is not permitted. This is to minimize risk to Laboratory employees and the public. This also ensures that the federal and state laws regarding packaging, manifesting, and placarding hazardous materials are met. There are exceptions for transporting research samples, hazardous materials, and field sampling materials, described later.

- The following parties are permitted to transport hazardous materials between non-adjacent Berkeley Lab buildings and from off-site locations (e.g., UC Berkeley campus):

- Transportation Services (ext. 5404) will transport hazardous materials, provided they are unopened and still in their original DOT shipping containers. They will also transport gas cylinders. In addition, Berkeley Lab Transportation Services will package and label hazardous materials in accordance with DOT Title 49 regulations for shipment by commercial carriers.

- SDSs and hazard warning container labels are required for off-site shipments of chemicals that are produced in LBNL laboratories. Refer to Work Process Z for hazard communication requirements for chemicals produced in laboratories.

- The EHS Waste Management Group (ext. 5877) will transport hazardous materials that have previously been opened. This is normally needed for laboratory moves.

- Facilities craft personnel will transport paints, solvents, cleaners, and other materials necessary to perform their work.

- Transporting Small Quantities of Hazardous Materials by Laboratory Employees, Subcontractors, and Affiliates

- Laboratory employees, subcontractors, and affiliates may move small quantities of hazardous materials for short distances within a building or between adjacent buildings, provided it can be done safely and without spilling the materials. Individuals must use a means of containing leaks and spills such as handcarts and drip trays, or bottle carriers. Employees must also complete Chemical Hygiene and Safety Training (EHS0348; or 345 for Facilities personnel). Use standard cylinder dollies to transport compressed gas cylinders. While dollies are preferred, cylinders weighing 11 kg (25 lbs) or less may be hand-carried.

- Never move a cylinder with a regulator connected to it. Cylinder valve-protection caps and valve-opening caps must be in place when moving cylinders. Lecture bottles and other cylinders not normally equipped with valve-protection caps should be transported in either the original DOT specification package or an equivalent container.

NOTE: Contact an EHS Radiological Control Technician for guidance on transporting radiological isotopes.

- Transporting Research Samples, Hazardous Materials, and Field Sampling Materials by Berkeley Lab Staff

- Policy and Procedures

- The policy for transporting research samples, hazardous materials, and field sampling materials by Berkeley Lab staff is established in the ES&H Manual Chapter 54 Transporting and Shipping Hazardous Materials program. The process described below is the procedure for implementing this policy.

- Berkeley Lab staff (i.e., anyone with a Berkeley Lab badge) may transport research samples and small quantities of hazardous materials by hand or in a passenger vehicle under the conditions defined by procedures described below. “Small quantities” is defined in Section 4, Scope and Application below. A research sample is a material used or developed in a laboratory for research purposes, for further use, study, analysis, or characterization.

- Shipping samples and hazardous materials by common carrier (FedEx, UPS, USPS) to off-site locations must be done by Facilities Material Services. This is addressed in Pub 3000 Chapter 54 Transporting and Shipping Hazardous Materials Work Process E, Shipping.

- Questions regarding this policy may be addressed to the EHS Deputy Division Director.

- Policy and Procedures

- Scope and Application

- This policy applies to Berkeley Lab staff who:

- Transport research samples (including engineered nanomaterials) and hazardous chemicals between:

- Buildings at the main Berkeley Lab site

- The main Berkeley Lab site and other Laboratory sites (e.g., Donner, Potter, JBEI, JGI)

- Any Berkeley Lab site and other collaborating research organization (e.g., UC Berkeley and Stanford)

- Transporting small quantities of hazardous materials to and from field locations not readily served by common carriers such as FedEx and UPS.

- Transport research samples (including engineered nanomaterials) and hazardous chemicals between:

- This policy applies to research samples and hazardous materials in the following DOT hazard categories. These materials must be contained in proper packaging (see below) and shall not exceed 0.5 kg (1 lb) or 0.5 L (1 pint) gross packaging size. To determine hazard class, consult a Safety Data Sheet (SDS) or contact the EHS Transportation Subject Matter Expert.

- Class 3 (flammable liquid)

- Class 8 (corrosive material)

- Class 9 (other regulated material)

- Division 4.1 (flammable solid)

- Division 5.1 (oxidizer)

- Division 5.2 (organic peroxide)

- Division 6.1 (toxic or poisonous)

- ORM-D (other regulated material, consumer commodity)

- Contact the EHS Deputy Division Director for exemptions to the above hazard class/quantity limitations, or for transporting materials in the following DOT hazard categories:

- Division 2.1 (flammable gas)

- Division 2.2 (nonflammable gas)

- This policy applies to Berkeley Lab staff who:

- Prohibitions. This policy does not apply to biological materials and materials that are radioactive, self-reactive, pyrophoric, explosive, water-reactive, acutely toxic by inhalation, or hazardous waste. “Acutely toxic” refers to substances that may be fatal or cause damage to target organs from a single exposure or from exposures of short duration. It also includes materials capable of causing intense irritation that can result in pulmonary edema (fluid and swelling in the lungs), chemical asphyxia, and systemic (body-wide) poisoning. A substance’s acute toxicity may be determined by consulting an SDS. Contact the EHS Transportation Subject Matter Expert for further information.

- Personnel Qualifications

- Staff transporting hazardous materials must have Chemical Hygiene and Safety Training (EHS0348), Chemical Hygiene and Safety Refresher Training (EHS0353) as applicable, and Safe Handling of Engineered Nanoscale Particulate Matter (EHS 0344) if they transport engineered nanoscale particulate matter. Furthermore, transporting research samples and small quantities of hazardous materials must be authorized in an employee’s WPC Activity.

- Facilities Material Services personnel who package materials for common carrier shipment must be qualified in accordance with the DOT or the International Air Transport Association (IATA) regulations.

- Packaging Requirements for Hand Carrying and Transportation by Vehicle

- An inner receptacle and outer packaging are required (see photos below):

- Containers can be procured from a variety of companies such as Grainger (formerly called Lab Safety Supply) or HAZMATPAC, Inc.

- The inner receptacle must be:

- Leak-tight, securely closed, and protected against damage. A screw-type cap or other positive means of closure is required. Parafilm, aluminum foil, and stoppers are prohibited.

- Labeled with the identity of the material, its hazard, the name and phone number of the sender, and the name and phone number of the recipient (if different from the sender). The chemical identity must be the common name or the DOT proper shipping name. Chemical formulas, abbreviations, or acronyms are prohibited. If the material is an engineered nanomaterial, include the following words on the label:

“Nanoscale — This material’s toxicity, reactivity, and other hazards may be greater than its macro-size forms” - Placed in a zip-lock bag or equivalent to serve as secondary containment in the event of a leak

- Sealed in an outer package

- The outer packaging must:

- Be made of rigid material such as a cardboard or plastic, or a metal box or pail

- Contain cushioning material to prevent breakage and to maintain each inner receptacle in an upright condition

- Have the same labeling as the inner receptacle

- Note: multiple chemicals in the same outer package must be chemically compatible with each other

| Inner receptacle with positive closure and label | Zip-lock bag to contain leaks/spills | Outer packaging |

- Communication of Chemical Hazards in Transport

- Staff transporting material must inform vehicle passengers about the research samples/hazardous materials being transported and the requirements of this policy.

- An SDS must be placed inside the outer package.

- Other Requirements for Staff Hand-carrying and Transporting by Vehicle

- Maintain possession and control of the material at all times.

- Transport the material directly to its final destination with no intermediate stops.

- Using Berkeley Lab shuttle buses and other modes of public transit is prohibited.

- Keep hazardous materials in the car trunk or truck bed. Do not transport in the passenger compartment.

- Use a DOT- or OSHA-approved safety can with a rated volume of 5 gallons or less to transport gasoline to field locations. Keep it in the open bed of a truck. Do not transport in the trunk or compartment of a passenger vehicle.

- DOT placarding is not required for vehicles provided that the quantity and classification criteria described in Scope and Application (above) are followed.

- Keep purchased materials intended for field use in the manufacturer’s original packaging. Otherwise, follow the packaging requirements as described above.

- Update the Chemical Management System for applicable containers moved to another location.

- Requirements for Shipping by Common Carrier

- The Cal/OSHA Hazard Communication Standard (8 CCR 5194) requires SDSs and container labels for research samples and hazardous chemicals that are shipped from laboratories. There is no exemption based on size or volume. Refer to Work Process Z for additional details and hazard communication requirements.

- ES&H Manual Chapter 54, Transporting and Shipping Hazardous Materials Work Process E, Shipping, also requires that only qualified individuals in Facilities Material Services (ext. 5084) may pack and ship these materials off site. Berkeley Lab employees intending to ship research samples and hazardous materials off site must:

- Label the material as described in Work Process C, Hand-Carrying or Self-Transport by Hand and Foot; and Work Process D, Self-Transport by Vehicle, of the Transporting and Shipping Hazardous Materials program. Also list the sender’s address.

- Prepare an SDS to be shipped with the material. Contact the Chemical Hygiene and Safety (CHSP) manager for guidance.

- Coordinate pickup with Facilities Material Services (ext. 5084).

- Notify the recipient prior to transport.

- Facilities Material Services shall:

- Arrange for pickup of the material

- Pack the material in accordance with DOT and/or IATA regulations

Work Process D. Berkeley Lab Chemical Inventory

- Purpose

- The purpose of the site-wide chemical inventory is to provide chemical users, EHS staff, and emergency response teams with accurate and up-to-date lists of hazardous chemicals stored on site. Furthermore, Cal/OSHA requires that a hazardous chemical list be maintained. Current chemical inventory reports must also be provided for compliance with DOE and City of Berkeley regulations. The inventory is also used to categorize chemicals into their respective hazard classes and to use this information as a tool to:

- Identify users of particular materials

- Communicate hazard information, including special controls or procedures

- Assist EHS in helping chemical users to determine if exposure assessments are needed

- Use of the chemical inventory permits emergency personnel to respond to unplanned releases with appropriate training, equipment, and organizational support. A well-maintained chemical inventory can also aid in internal Laboratory management of business and research needs.

- The purpose of the site-wide chemical inventory is to provide chemical users, EHS staff, and emergency response teams with accurate and up-to-date lists of hazardous chemicals stored on site. Furthermore, Cal/OSHA requires that a hazardous chemical list be maintained. Current chemical inventory reports must also be provided for compliance with DOE and City of Berkeley regulations. The inventory is also used to categorize chemicals into their respective hazard classes and to use this information as a tool to:

- Responsibilities

- The EHS Division hosts the site-wide chemical inventory database within the Chemical Management System (CMS).

- All hazardous materials are required to be included in the CMS. SDSs for materials should be consulted to determine hazard status. An EHS Health and Safety Representative may be consulted to help determine the hazards of a chemical or product.

- Division Directors are responsible for ensuring a full, wall-to-wall chemical inventory reconciliation is completed within their division at least once every two years, which will include laboratory and technical area safety surveys performed by EHS. They are also responsible for the timely resolution of non compliances resulting from these activities.

- Chemical Owners

- The chemical owner must maintain an accurate inventory of all hazardous chemicals/materials for which they are responsible for in the Chemical Management System (CMS). This includes ensuring hazardous chemicals and gases are inventoried in CMS with the correct information and that the container records are disposed of in the inventory when the materials have been used up, disposed of, or taken off-site.

- The chemical owner is accountable and responsible for the proper labeling, testing, management, and recordkeeping for his/her peroxide-forming and other time sensitive chemicals. The chemical owner may choose to assign time sensitive chemical labeling, testing, management and recordkeeping tasks to his/her proxies.

- Before vacating an area or leaving the Lab, the chemical owner must make sure that all hazardous materials are removed, transferred to new ownership, or properly disposed of.

- A chemical owner is accountable for the safe storage of hazardous chemicals, though all chemical users share the responsibility to use and store hazardous materials safely. Safe chemical usage is a Line Management responsibility.

- A chemical owner must provide the resources to make safe storage possible. This includes the purchase of equipment and accessories — such as cabinets and storage containers for flammables and corrosives — to control hazards. The chemical owner must have the authority to set administrative controls such as procedures for safe storage of chemicals. Guests, students, visiting scientists, and other short-term staff usually do not meet these requirements, but it is up to each division to assign ownership of chemicals and hazardous materials.

- Chemical Management System (CMS)

- There are two ways chemicals are added to CMS, depending on their method of acquisition (Chemical Acquisition Resource).

- For chemicals ordered through LBNL’s Financial Management System (FMS), including eBuy and ePro, purchase requesters must indicate whether each requisition line item being ordered is a hazardous chemical or compressed or liquified gas by answering YES then entering the required information. Answering YES will automatically create an inventory record in CMS and information will be sent for screening and approval prior to the order proceeding.

- For hazardous chemicals (including compressed or liquified gas cylinders) that require CMS tracking to be acquired outside of FMS, including, but not limited to, primary manufacturer containers from collaborators or those acquired through a non-LBNL purchasing system then transported to LBNL, the hazardous chemical procurement decision maker (e.g., Requestor) must ensure these chemicals are added directly in CMS prior to arrival on site. Chemicals must be added in CMS with “ordered” status and will be routed for the same screening and approval process as for chemicals ordered in FMS.

- If a container does not require CMS tracking (e.g. research samples), the Requestor is responsible for assuring the scope of work, including hazards, controls, and material quantities are covered by an authorized Work Activity.

- In any case, necessary approvals must be in place prior to arrival onsite, including approvals for materials falling under the Physical Security Program’s hazardous materials management policy and the Procurement Restricted Items List.

- The CMS identifies containers (or groups of identical containers) with a radio-frequency identification (RFID) Tag containing a seven-digit ID number. The tag should be affixed to the container with the ID number completely visible. Refer to the RFID Tagging Guide for resources on applying RFID tags on containers. RFID tags can be obtained through chemical management CMS@lbl.gov or via request form.

- The following information must be in CMS for each chemical:

- Container RFID Tag ID number

- Chemical or product name

- Chemical or product concentration

- Container size

- Container unit (kg, l, ml, etc.)

- Container type (glass bottle, can, etc.)

- Physical state (solid, liquid, gas)

- Manufacturer

- Temperature

- Pressure

- Building

- Room

- Owner

- Note: When entering groups of materials or materials with a high throughput rate in a specific room, such as commonly used organic solvents, acids, and bases, a CMS record can represent multiple identical containers in CMS, with exceptions noted under 5.g. This is referred to as a static RFID tag or a multi-container record. In such cases, the maximum amount possible should be indicated in the Size/Unit of the record.

- Contact Chemical Management System Support at CMS@lbl.gov for information on inventory implementation and training.

- There are two ways chemicals are added to CMS, depending on their method of acquisition (Chemical Acquisition Resource).

- Content Guidance (Content Guidance Resource)

- All hazardous materials/chemicals must be entered into the database, with the following exceptions:

- Biological Agents that are not toxins

- Biochemical materials such as cell-culture media, amino acids, or lipids that have been determined to be nonhazardous using available health and safety information

- Chemicals or chemical products transferred to secondary/split/child (nonmanufacturer) containers, if the primary container is accounted for accurately in CMS in terms of total quantity and location (e.g. room), but need to be labeled with content and primary hazard(s) at the minimum. These are jars, cans, squeeze bottles, and other containers to which hazardous materials are transferred from the original container by an individual. NOTE: Tracking splits of high hazard chemicals (under a new container record for the date of split created) is recommended as a best practice, if stored, to ensure they are accounted for if the primary container is disposed of in CMS. Tracking splits of time-sensitive chemicals, including peroxide-forming chemicals, is required, if stored, to ensure that time-sensitive hazards are mitigated. Process Guidance for Splits

- 🚩Samples such as research-produced chemicals and mixtures (follow labeling requirements in Work Process Y (Process guidance for samples)🛑

- Radiological materials that are tracked in RADAR

- Chemicals transferred to waste container

- Individual components of prepackaged chemical kits (see below)

- Consumer products, which can be excluded from the CMS if their usage is consistent with how the manufacturer intends the average consumer to use the product. Example: Bleach that is used infrequently for cleaning can be excluded. However, bleach that is used daily for work tasks such as disinfecting work surfaces in a tissue-culture laboratory is beyond what is considered average consumer usage as intended by the manufacturer and must be entered into CMS.

- All consumer adhesives and sealants must be inventoried.

- All gas cylinders shall be inventoried.

- Mixtures. The product name should be entered in CMS and the components and their concentration should be specified in the container comment field unless the information is included in the product name. It is recommended that you attach the Safety Data Sheet of the mixture to the container record in CMS. Examples: “nitric acid 65%” as the product name, “Nickel Standard for ICP” as the product name with container comment “nickel(II) nitrate 0.1%-1% and nitric acid 3%-5%”, “25PPM Hydrogen Sulfide, 100PPM Carbon Monoxide, 2.5% Methane, 18% Oxygen Balance Nitrogen Certified Standard Mixture“ as the product name.

- Consumable materials such as grinding wheels, welding rods, or solder material that can be used up, dispersed, or aerosolized during use must be entered into the CMS.

- Prepackaged kits that are sets of chemical components intended for use for a specific task, test, or procedure, must be entered into the CMS. NOTE: Individual components do not need to be entered individually. The kit may be entered as a whole, identified by the name as it appears on the manufacturer’s SDS.

- Multi-container Data Sheets/Static RFID Tag (Template 1 / Template 2, How-To Website)

- These can be used for groups of identical containers within a specific room in lieu of RFID tagging individual items. These sheets must be posted at or near the storage location. The number of containers represented by the RFID tag on a multi-container data sheet must be clearly identified. If the number of identical containers varies, a max amount possible should be identified (and should not be exceeded at any time). List the total quantity of all containers not to be exceeded in CMS (see examples, iii).

- Exceptions:

- Static RFID tags cannot be used for toxic or corrosive gas cylinders (e.g. NFPA Health Hazard Class 3 and 4, or Class 2 with poor warning properties) to enable accurate tracking.

- California and DOE regulations on the use of greenhouse gases require Berkeley Lab to report amounts annually. This multi-container option does not apply to greenhouse gases such as sulfur hexafluoride (SF6). All greenhouse gases such as SF6 must be individually entered into the CMS to enable accurate reporting.

- Static RFID tags for time-sensitive chemical solvents such as tetrahydrofuran and diethyl ether are not recommended to ensure containers are not lost or forgotten and accurate CMS tracking of container age.

- Examples of multi-container data sheets in use:

- All hazardous materials/chemicals must be entered into the database, with the following exceptions:

| Situation | Multi-container Data Sheet |

|

Gas cylinder storage area with:

| Sheet is posted clearly above gas storage racks:

|

|

Flammables storage cabinet containing:

|

Sheet is posted on the outside of the flammables cabinet:

|

|

Advanced Usage!

|

Two separate sheets with two separate RFID tags are posted:

Using this method, one cylinder can be moved from Room 100 to Room 200 and back as often as needed without the need to update CMS to reflect the change in room. |

h. Accessing CMS:

- CMS can be accessed at cms2.lbl.gov using your LDAP (same as email) username and password.

- Please contact CMS Support at CMS@lbl.gov for database access, editing privileges, setting up owner and rooms, and information regarding roles and responsibilities.

Work Process E. Chemical Hazard Evaluation: Identification, Classification, and Categorization

- Purpose of Chemical Hazard Evaluations

- Chemical hazard evaluations are conducted at LBNL to:

- Identify hazards of chemicals that are used in work activities for establishing engineering, work practice, administrative and training controls. These are conducted by Activity Leads and safety professionals for developing WPC Activities and for providing consultation to the Laboratory community. Refer to Work Process F.

- Classify and categorize the hazards of chemicals produced in laboratories to comply with Cal/OSHA Hazard Communication requirements.

- The Cal/OSHA Hazard Communication Standard (HCS) requires chemical manufacturers, importers and distributors to identify, classify and categorize the hazards of chemicals they produce. LBNL is regarded as a chemical manufacturer when chemicals produced in laboratories are shipped off site, and therefore must follow the hazard classification process prescribed by Cal/OSHA. Section 2 outlines these requirements. (Note: Due to the complex and prescriptive requirements for classifying chemicals, and for developing SDSs and labels under Cal/OSHA, researchers may consult with the CHSP manager for assistance.) In addition, LBNL must communicate these hazards to downstream users in the form of SDSs and labels. Refer to Work Process Z for additional details and hazard communication requirements for chemicals produced in laboratories.

- Chemical hazard evaluations are conducted at LBNL to:

- Chemical Hazard Definition, Classification and Categorization

- A hazardous chemical is any chemical classified as a health hazard or a physical hazard:

- Health Hazard: is a chemical posing one of the following hazardous effects: acute toxicity (any route of exposure); skin corrosion or irritation; serious eye damage or eye irritation; respiratory or skin sensitization; germ cell mutagenicity; carcinogenicity; reproductive toxicity; specific target organ toxicity (single or repeated exposure); or aspiration hazard.)

- Physical Hazard: is a chemical posing one of the following hazardous effects: explosive; flammable (gases, aerosols, liquids, or solids); oxidizer (liquid, solid or gas); self-reactive; pyrophoric (liquid or solid); self-heating; organic peroxide; corrosive to metal; gas under pressure; or in contact with water emits flammable gas.

- Cal/OSHA Hazard Classification and Categorization Process (Required for Chemical Manufacturers)

- Hazard classification is the process of evaluating available scientific evidence to determine if a chemical is hazardous, as well as to identify the level of severity of the hazardous effect. A hazard class is the type of health or physical hazard (e.g., acute toxicity and flammable liquid). A hazard category is the level of severity within each hazard class. When complete, the evaluation identifies the hazard class and hazard category of the chemical. This information is then used to develop SDSs and labels in order to communicate hazards to downstream users.

- The specific criteria for determining the hazard class and category are outlined in Appendices A and B of the HCS. Appendix A provides the classification criteria for health hazards and Appendix B provides the classification criteria for physical hazards. The OSHA publication, Hazard Communication: Hazard Classification Guidance for Manufacturers, Importers, and Employers, provides guidance for carrying out hazard classification.

- Testing of chemicals is not required by Cal/OSHA, but the full range of available scientific literature and other evidence concerning the potential hazards of chemicals to be considered in classifying chemical hazards must be considered.

- Due to the complex and prescriptive requirements for classifying chemicals, and for developing SDSs and labels under Cal/OSHA, researchers may consult with the CHSP manager for assistance.

- A hazardous chemical is any chemical classified as a health hazard or a physical hazard:

Note: LBNL is not required to use the process described above for routine hazard identification and evaluation conducted by Activity Leads and safety professionals in developing WPC Activities and providing consultation for work involving commercially procured chemicals.

- Information and Resources for Identifying and Evaluating Chemical Hazards. The following sources of information may be used to identify, classify and assess the hazards of chemicals. This is not an exhaustive list:

- The EH&S Safety Data Sheets and Chemical Information Resources site. This has several links to SDS databases and other toxicological and hazard resources.

- The Work Processes of the CHSP, in particular, Work Processes L-T (Specific Controls and Procedures).

- 8 CCR 5155, Airborne Contaminants, Table AC-1 has a list of hazardous chemicals and their respective airborne permissible exposure limits.

- Threshold Limit Values for Chemical Substances and Physical Agents in the Work Environment, American Conference of Governmental Industrial Hygienists (ACGIH), latest edition: Includes a list of hazardous chemicals and their respective airborne occupational exposure limits.

- International Agency for Research on Cancer (IARC): Evaluates the carcinogenicity of chemicals and ranks their carcinogenic potential. Chemicals with IARC classifications of 1, 2A, and 2B are considered by Cal/OSHA to be carcinogenic.

- National Toxicology Program (NTP) biennial Report on Carcinogens, latest edition: Chemicals with NTP classifications of A or B are considered by Cal/OSHA to be carcinogenic.

- National Institute for Occupational Safety and Health (NIOSH) Pocket Guide to Chemical Hazards: Presents the health and physical hazards of chemicals.

- The Registry of Toxic Effects of Chemical Substances (RTECS), National Institute for Occupational Safety and Health NIOSH (latest edition)

- Bretherick’s Handbook of Chemical Reactive Hazards

- Prudent Practices in the Laboratory: Handling and Management of Chemical Hazards, Updated Version.

Work Process F. Use and Application of Chemical Hazard Assessments

- Chemical hazard assessments are conducted to identify the hazards and necessary controls for chemicals used in shop, field, and laboratory work environments. The inherent chemical and physical hazards (i.e., hazard class and category) as well as the manner in which chemicals are used, are considered. Specifically, hazard assessments are performed to:

- Develop Work Planning and Control (WPC) activities – WPC is a review and management-approval process designed to ensure that procedures, controls, and resources are in place before work begins. Activity Leads develop activities by defining work, identifying hazards associated with the work, and implementing controls. The Activity Lead is also responsible for assigning and authorizing workers to perform work. Consult the Work Planning and Control program (EH&S Manual Chapter 6) for additional details and requirements.

- Perform Exposure Assessments – EHS Health and Safety Representatives identify the potential for exposure to chemicals and provide options for minimizing risk through hazard elimination, engineering controls, personal protective equipment (PPE), and administrative controls. These assessments are generally qualitative, although quantitative exposure assessments (collection and analysis of air and bulk samples) may be performed.

- Perform respiratory protection evaluations – EHS Health and Safety Representatives evaluate chemical usage and work activities for recommending respiratory protection.

- In accordance with Integrated Safety Management (ISM) Activity Leads and Project Leads are responsible for “integrating EHS into work and for ensuring active communication up and down the management line with the workforce.” To this end, they must be aware of and authorize the work performed under their jurisdiction and ensure that appropriate hazard assessments and exposure assessments, as necessary, are conducted in their work areas.

- Laboratory and technical area safety surveys will be performed by EHS in each lab and technical area at least once every two years to assure chemical hazard and exposure assessments are conducted as needed. During the surveys, work scope will be discussed and safety of the areas will be evaluated.

- All work performed at Berkeley Lab must be authorized through WPC or an equivalent work authorization process (e.g. User authorization processes at the ALS or the Molecular Foundry). The Laboratory protocol for determining the proper level of work authorization is delineated in the Pub 3000 Chapter 6, Safe Work Authorizations program. The ultimate determination of the appropriate work authorization is the responsibility of the Project Lead (with approval from a worker’s manager/supervisor for Risk Level 3 activities) for that work.

- The Cal/OSHA Laboratory Standard requires that employers identify higher hazard work that requires prior approval. At LBNL, that is accomplished through WPC. With regard to chemicals, three WPC risk levels were established:

- Risk level 1 chemicals are those routinely found in most labs. They include materials such as flammable/combustible liquids, acids and bases, where the use of standard safe laboratory practices and controls such as fume hoods, proper storage, housekeeping and PPE can adequately control the hazards.

- Risk level 2 chemicals are also common but they have a higher degree of inherent hazard and require more specialized controls. These include materials such as Cal/OSHA “Particularly Hazardous Substances” (e.g., reproductive toxins and carcinogens), peroxide formers, and phenol. Risk level 1 controls (fume hood, PPE, etc.) apply to these materials, but due to their nature, additional controls are required. For example, particularly hazardous substances need to be used in “designated areas”, peroxide formers require labeling and testing and emergency exposure kits are needed for phenol.

- Risk level 3 chemicals have the highest degree of hazard, in which a loss of control could result in immediate injury or death, and therefore require a higher level of control and authorization. These include water reactives, pyrophorics, lethal toxicants, and secondary explosives. Below are several lists of chemicals that can trigger risk level 3 activities. Note these lists are NOT exhaustive. Other sources such as those listed in Work Process E may be consulted. An EHS Health and Safety Representative may also be consulted.

- Toxic/Pyrophoric Gases

| 1,3-butadiene | iodine pentafluoride |

| ammonia | methyl bromide |

| arsenic pentafluoride | methyl chloride |

| arsine | methyl silane |

| boron trichloride | nickel carbonyl |

| boron trifluoride | nitric oxide |

| bromine pentafluoride | nitrogen dioxide |

| bromine trifluoride | nitrogen trifluoride |

| carbon monoxide | nitrosyl chloride |

| carbonyl fluoride | oxygen difluoride |

| carbonyl sulfide | phosgene |

| chlorine | phosphine |

| chlorine trifluoride | phosphorus pentafluoride |

| cyanogen | phosphorus trichloride |

| cyanogen chloride | phosphorus trifluoride |

| diborane | selenium hexafluoride |

| dichlorosilane | silane |

| fluorine | silicon tetrafluoride |

| germane | stibine |

| hydrogen bromide | sulfur dioxide |

| hydrogen chloride | sulfur tetrafluoride |

| hydrogen cyanide | sulfuryl fluoride |

| hydrogen fluoride | tellurium hexafluoride |

| hydrogen selenide | tungsten hexafluoride |

| hydrogen sulfide | vinyl chloride |

- Reactive and Explosive Substances

| aluminum hydride | picric acid |

| benzoyl peroxide | potassium |

| cesium | rubidium |

| copper azide | sodium |

| lead azide | sodium azide |

| lithium | triethyl aluminum |

| phosphorus (white) | trimethyl aluminum |

- Chemicals Possessing Lethal or Incapacitating Toxicity

| Amiton: O,O-Diethyl S-[2-(diethylamino)ethyl] phosphorothiolate and corresponding alkylated or protonated salts (78-53-5) |

| O-Alkyl (<C10, incl. cycloalkyl) alkyl (Me, Et, n-Pr or i-Pr)-phosphonofluoridates Sarin: O-Isopropyl methylphosphonofluoridate (107-44-8) Soman: O-Pinacolyl methylphosphonofluoridate (96-64-0) |

| O-Alkyl (<C10, incl. cycloalkyl) N,N-dialkyl (Me, Et, n-Pr or i-Pr) phosphoramidocyanidates Tabun: O-Ethyl N,N-dimethyl phosphoramidocyanidate (77-81-6) |

| O-Alkyl (H or <C10, incl. cycloalkyl) S-2-dialkyl (Me, Et, n-Pr or i-Pr)-aminoethyl alkyl(Me, Et, n-Pr or i-Pr) phosphonothiolates and corresponding alkylated or protonated salts VX: O-Ethyl S-2-diisopropylaminoethyl methyl phosphonothiolate [50782-69-9] |

| Sulfur mustards: 2-Chloroethylchloromethylsulfide [2625-76-5] Mustard gas: Bis(2-chloroethyl)sulfide [505-60-2] Bis(2-chloroethylthio)methane [63869-13-6] Sesquimustard: 1,2-Bis(2-chloroethylthio)ethane [3563-36-8] 1,3-Bis(2-chloroethylthio)-n-propane [63905-10-2] 1,4-Bis(2-chloroethylthio)-n-butane [142868-93-7] 1,5-Bis(2-chloroethylthio)-n-pentane [142868-94-8] Bis(2-chloroethylthiomethyl)ether [63918-90-1] O-Mustard: Bis(2-chloroethylthioethyl)ether [63918-89-8] |

| Lewisites: Lewisite 1: 2-Chlorovinyldichloroarsine [541-25-3] Lewisite 2: Bis(2-chlorovinyl)chloroarsine [40334-69-8] Lewisite 3: Tris(2-chlorovinyl)arsine [40334-70-1] |

| Nitrogen mustards: HN1: Bis(2-chloroethyl)ethylamine [538-07-8] HN2: Bis(2-chloroethyl)methylamine [51-75-2] HN3: Tris(2-chloroethyl)amine [555-77-1] |

| Saxitoxin [35523-89-8] |

| Ricin [9009-86-3] |

| Alkyl (Me, Et, n-Pr or i-Pr) phosphonyldifluorides DF: Methylphosphonyldifluoride [676-99-3] |

| O-Alkyl (H or <C10, incl. cycloalkyl) O-2-dialkyl(Me, Et, n-Pr or i-Pr)-aminoethyl alkyl(Me, Et, n-Pr or i-Pr) phosphonites and corresponding alkylated or protonated salts QL: O-Ethyl O-2-diisopropylaminoethyl methylphosphonite [57856-11-8] |

| Chlorosarin: O-Isopropyl methylphosphonochloridate [1445-76-7] |

| Chlorosoman: O-Pinacolyl methylphosphonochloridate [7040-57-5] |

| PFIB: 1,1,3,3,3-Pentafluoro-2-(trifluoromethyl)-1-propene [382-21-8] |

| BZ: 3-Quinuclidinyl benzilate (*) [6581-06-2] |

| Chemicals containing a phosphorus atom to which is bonded one methyl, ethyl, or propyl (normal or iso) group but no further carbon atoms Methylphosphonyl dichloride [676-97-1] Dimethyl methylphosphonate [756-79-6] Exemption: Fonofos: O-Ethyl S-phenyl ethylphosphonothiolothionate [944-22-9] |

| N,N-Dialkyl (Me, Et, n-Pr or i-Pr) phosphoramidic dihalides |

| Dialkyl (Me, Et, n-Pr or i-Pr) N,N-dialkyl(Me, Et, n-Pr or i-Pr)-phosphoramidates |

| Arsenic trichloride [7784-34-1] |

| 2,2-Diphenyl-2-hydroxyacetic acid [76-93-7] |

| Quinuclidin-3-ol [1619-34-7] |

| N,N-Dialkyl (Me, Et, n-Pr or i-Pr) aminoethyl-2-chlorides and corresponding protonated salts |

| N,N-Dialkyl (Me, Et, n-Pr or i-Pr) aminoethane-2-ols and corresponding protonated salts Exemptions: N,N-Dimethylaminoethanol and corresponding protonated salts [108-01-0] N,N-Diethylaminoethanol and corresponding protonated salts [100-37-8] |

| N,N-Dialkyl (Me, Et, n-Pr or i-Pr) aminoethane-2-thiols and corresponding protonated salts |

| Thiodiglycol: Bis(2-hydroxyethyl)sulfide [111-48-8] |

| Pinacolyl alcohol: 3,3-Dimethylbutan-2-ol [464-07-3] |

- The following chemicals also exhibit toxic properties of concern. An EHS Health and Safety Representatives must be consulted prior to purchase and use of these chemicals to determine if additional work authorization or approvals are required:

| Chemical Name [CAS#] |

| Phosgene: Carbonyl dichloride [75-44-5] |

| Chloropicrin: Trichloronitromethane [76-06-2] |

| Phosphorus oxychloride [10025-87-3] |

| Phosphorus trichloride [7719-12-2] |

| Phosphorus pentachloride [10026-13-8] |

| Trimethyl phosphite [121-45-9] |

| Triethyl phosphite [122-52-1] |

| Dimethyl phosphite [868-85-9] |

| Diethyl phosphite [762-04-9] |

| Sulfur monochloride [10025-67-9] |

| Sulfur dichloride [10545-99-0] |

| Thionyl chloride [7719-09-7] |

| Ethyldiethanolamine [139-87-7] |

| Methyldiethanolamine [105-59-9] |

| Triethanolamine [102-71-6] |

Work Process G. General Controls for Hazardous Chemicals

This work process discusses control procedures for limiting employee exposure to chemical hazards.

- Standard Operating Procedures. Standard operating procedures for all chemicals at Berkeley Lab are intended to minimize employee exposure to hazards, and include: chemical substitution, engineering controls, administrative controls, personal protective equipment, work practice controls, and emergency procedures, all of which are described in this section. All employees are required to wear eye protection, lab coats, and chemically resistant gloves when handling hazardous chemicals. Operations that may generate airborne gases, vapors, dusts, fumes, and smoke must be done in a fume hood or glove box. In addition, specific controls for the following classes of hazardous materials are described in more detail below. Activity Leads shall ensure that all work involving these hazardous chemicals is evaluated, controlled, documented, and approved in a WPC Activity.

- Acids and Bases (Work Process L)

- Particularly Hazardous Substances (Work Process M)

- Carcinogens (Work Process M.1)

- Reproductive Toxins (Work Process M.2)

- Flammables and Combustible Liquids (Work Process N)

- Laser Dyes and Solvents (Work Process O)

- Peroxide-Forming Compounds (Work Process P)

- Water-Reactive Chemicals (Work Process Q)

- Pyrophoric Materials (Work Process R)

- Chemical Synthesis (Work Process R.1)

- Engineered Nanomaterials (Work Process S)

- Chemicals with Explosive Properties (Work Process T)

Chemical Purchasing

- Determine whether the chemical is a restricted item. If it is, the person making the decision to purchase the chemical or giving permission to another institution to have it delivered to Berkeley Lab must ensure notification or approval is obtained from the EHS Division in accordance with the Laboratory’s procurement requirements. Refer to Work Process B for additional details.

- Determine whether the chemical is a restricted item. If it is, the person making the decision to purchase the chemical or giving permission to another institution to have it delivered to Berkeley Lab must ensure notification or approval is obtained from the EHS Division in accordance with the Laboratory’s procurement requirements. Refer to Work Process B for additional details.

- Chemical Use, Selection, and Substitution. Before a chemical or a product is introduced or used in a workplace, the Activity Lead must:

- Review the hazards of the material and assess the conditions under which it will be used. This information may be obtained from the SDS or by consultation with EHS Health and Safety Representatives. Work Process E lists information and resources for identifying and evaluating chemical hazards.

- Determine whether the chemical can be substituted with a safer chemical alternative. An EHS Health and Safety Representatives can be consulted to provide assistance to identify substitute chemicals.

- Determine whether the chemical can be borrowed from someone within the research group or the division. If the chemical must be purchased, keep working quantities of all hazardous materials to a minimum. Procure, use, and store the minimum amount of material required.

- Chemicals Produced in Laboratories. Chemicals produced in laboratories must, at a minimum, be evaluated for their hazards. Other requirements such as training, and the production of SDSs and labels vary depending on whether the materials will be shipped off site or used on-site. Refer to Work Process Z for additional details and hazard communication requirements for chemicals produced in laboratories.

Work Process H. Selection and Use of Engineering Controls

Engineering controls include local exhaust ventilation systems, laboratory fume hoods, enclosures, and shields. Except for substitution, these provide the most effective means of control because they enclose the hazard or physically separate it from the employee.

- Local Exhaust Ventilation, Fume Hoods

- Local exhaust ventilation and laboratory fume hoods are used to remove airborne contaminants from an employee’s breathing zone. Self-contained (ductless) hoods that recirculate air back into the workspace are not an acceptable means to control airborne chemicals. The selection, procurement, installation, and balancing of all ventilation systems must be done through Facilities.

- Local exhaust ventilation (such as laboratory fume hoods, glove boxes, extractor arms, or industrial ventilation) is required when handling chemicals in a manner that can produce an airborne hazard.

- Examples of activities requiring local exhaust ventilation include but are not limited to:

- Using particularly hazardous substances (i.e., acutely toxic, carcinogenic, or reproductive toxins)

- Handling volatile toxic liquids

- Using organic liquids or solvents

- Conducting procedures that generate airborne particulates (e.g., dust) or liquid aerosols of even moderately toxic chemicals

- Using odiferous compounds

- Synthesizing or reacting chemicals

- Diluting concentrated acids and bases. NOTE: Operations involving heating or evaporating perchloric acid must be evaluated by an EHS Health and Safety Representative to determine whether special controls (such as using an acid fume hood with wash-down systems to prevent the accumulation of explosive perchlorate crystals) are needed

- Discharging gases/vapors from vacuum pumps and distillation columns

- Discharging harmful gases and vapors from drying ovens and muffle furnaces; NOTE: Consult an EHS Health and Safety Representative to help make this determination.

- Performing operations that could generate a flammable atmosphere

- Transfers of flammable and combustible liquids from one container to another. Refer to Work Process N.11, “Transfer Operations,” for specific guidance and requirements regarding these transfers.

- Fume hoods, gas cabinets, and other ventilated enclosures must be equipped with electronic flow sensors or pressure gauges. If the flow sensor alarm goes off (red light, warning sound) or the pressure falls below the indicated set point on the pressure gauge, discontinue work in that system and call the Work Request Center (ext. 6274; for after-hours emergency service, call ext. 5481) to report the condition. Do not simply mute the alarm and continue working — the alarm indicates that something is not operating correctly. If the system is restored and the alarm resets, you may resume work, but you should report the condition so that the cause may be investigated.

- Local exhaust ventilation and laboratory fume hoods are used to remove airborne contaminants from an employee’s breathing zone. Self-contained (ductless) hoods that recirculate air back into the workspace are not an acceptable means to control airborne chemicals. The selection, procurement, installation, and balancing of all ventilation systems must be done through Facilities.

- Glove Boxes and Gas Cabinets

- Glove boxes that provide a nonreactive atmosphere are required for operations involving alkali metals and pyrophoric materials. Fume hoods may also be used provided that measures are taken to prevent control moisture and air, such

- Gas cabinets are required for health-hazard and pyrophoric gases as described in ES&H Manual Chapter 13 Gas Safety program. NOTE: Fume hoods may be used for this purpose as well, based on review and concurrence from an EHS Health and Safety Representative.

- Chemical Storage Cabinets

- New flammable storage cabinets must be connected to the building’s exhaust system. This applies to all flammable storage cabinets installed during renovation or new construction. Refer to Work Process N for additional requirements for flammable storage cabinets.

- Existing flammable storage cabinets showing signs of interior corrosion or whose contents produce strong odors during storage shall also be ventilated.

- It is recommended that new corrosive storage cabinets be connected to the building’s exhaust system. Existing cabinets may also need to be connected if they show signs of corrosion or produce odors. Consult with your Division’s Health and Safety Representative for guidance.

- Laboratory Room Exhaust. Laboratory heating, ventilating, and air conditioning (HVAC) systems must provide 100% outside air to laboratory spaces (no recirculation of air is allowed). The HVAC systems are balanced to keep laboratory spaces at a negative pressure relative to adjacent offices and hallways. This ensures that vapors, gases, fumes, and particulates do not migrate to non-laboratory spaces. A minimum ventilation rate of 1 cubic foot per minute of exhaust per square foot of laboratory area is required. Exceptions to maintaining negative pressure in a laboratory can be made provided that it can be demonstrated that research is adversely affected by ambient air drawn into the workspace and that EHS Health and Safety Representative concurrence has been obtained.

- Ventilation System Performance Evaluations

- Facilities is responsible for installing, balancing, and function testing all ventilation devices.

- EHS Health and Safety Representatives perform periodic testing of fume hoods, gas cabinets, glove boxes, canopy hoods, and extractor arms. These are evaluated initially after installation. Fume hoods used for radiological work are evaluated annually, while fume hoods used for non-radiological work are evaluated every two years (with an annual spot check in between formal evaluations). All other ventilation units – gas cabinets, glove boxes, canopies, and extractor arms – are evaluated annually.

- Ventilation system performance must be checked whenever the system has been modified, such as by adding new hoods or relocating or replacing system components (including hoods).

- Safety Shields. Safety shields must be used for protection against possible explosions or uncontrolled reactions. Laboratory equipment must be shielded on all sides to ensure there is no line-of-sight exposure of personnel.

Work Process I. Personal Protective Equipment

Personal protective equipment (PPE) is to be used as a supplement to but not as a substitute for engineering controls. PPE includes chemically resistant gloves, eyewear, footwear, lab coats, aprons, coveralls, and respiratory protection. PPE may be used as a sole means of control if the use of other controls is not feasible. PPE is provided at no personal expense to the individual. To be effective, employees must understand the proper selection, use, and limitations of PPE. For additional information on Berkeley Lab’s policies on PPE, see the ES&H Manual Personal Protective Equipment program.

- General PPE Requirements

- Skin and eye contact must be prevented. PPE must be selected on the basis of the hazards present, the type of materials used, and the manner in which they will be handled. Activity leads are responsible for ensuring that PPE use is included in WPC activities and for ensuring that employees use PPE properly.

- Employees must be trained in the uses and limitations of PPE. This is the activity lead’s responsibility. An EHS Health and Safety Representative may be consulted to provide guidance on the selection and use of PPE and to assist in training.

- Employees must report problems (such as deterioration and degradation) to activity leads immediately.

- Removing PPE

- Remove lab coats, coveralls, and gloves prior to leaving technical areas (labs, workrooms, and similar areas) when going to common areas such as lunchrooms, conference rooms, offices, restrooms, and the cafeteria.

- Remove gloves before touching common use items such as phones, computers, light switches, and doorknobs.

- Remove lab coats, coveralls, and gloves used for protection against engineered nanomaterials before leaving the area, regardless of your destination.

- The above requirements also apply to technical areas where biological materials are used.

- Disposing of PPE

- Normally, disposable PPE used in laboratory settings (such as gloves, Tyvek coveralls, and booties) may be disposed of as regular trash. However, PPE used for protection against materials such as engineered nanomaterials, lead, and asbestos must be disposed of as hazardous waste. Consult with an EHS Waste Generator Assistant for more information.

- Consult with a radiological control technician for disposing of PPE used in radiological areas.

- Dispose of PPE used for protection against biological materials in accordance with Berkeley Lab medical waste management procedures.

- Minimum PPE Requirements

- Area PPE Requirements

- Area PPE requirements must be established for all technical areas. This is the responsibility of the area safety leader through consultation with supervisors and activity leads.

- Area PPE requirements must be listed on the Berkeley Lab entrance placard.

- Area PPE requirements apply to the entire technical area unless an exception is granted in accordance with the procedure described in Appendix A, PPE and Food/Drink Requirements and Responsibilities Table, of the Personal Protective Equipment (PPE) program in the ES&H Manual.

- Minimum Area PPE requirements for technical areas are as follows (this applies to visitors as well as Lab personnel):

- Safety glasses with side shields

- Closed-toe shoes

- Long pants

- Area PPE Requirements

- Gloves

- Gloves must be worn when using hazardous chemicals, when handling materials at temperature extremes, or when handling materials with sharp or rough surfaces. It is especially important to wear gloves when handling chemicals that can be absorbed through the intact skin. Consult SDSs and the OSHA Occupational Chemical Database to identify chemicals that have this property. This may not be a complete list; therefore, contact an EHS Health and Safety Representative if you have any questions about a particular compound.

- Store gloves in a clean area outside of fume hoods and away from equipment that could potentially contaminate them.

- Always remove gloves before touching common use items such as phones, doorknobs, and computers. This will prevent contamination of unprotected individuals.

- Glove Selection

- Chemically resistant gloves are manufactured from a variety of materials, including nitrile, polyvinyl chloride, natural rubber (latex), and Viton. No single glove material provides universal protection against all chemical agents. Therefore, gloves must be selected on the basis of their resistance to the material(s) being handled, their suitability for the procedures being conducted, and their resistance to wear as well as temperature extremes.

- Improper selection may degrade the gloves, allow the chemical to permeate through the gloves, and ultimately expose the wearer to the chemical. This is a potentially serious situation. Use chemical resistance charts and glove selection databases (below) to choose gloves.

- In addition to the specific chemical(s), other factors to consider in selecting gloves are how and where they will be used. In shop environments, gloves may be subjected to rougher handling and may be totally immersed in chemicals such as cleaners and degreasers. In labs, manual dexterity may be an issue; splashes, as opposed to total immersion in the chemical, are more common. Gloves used in shop settings are thus required to be more resistant to tears and abrasion than those used in laboratory environments and are normally thicker (greater than 10-15 mils). In laboratories, thin, lightweight gloves are generally preferred (less than 10 mils). As a point of reference, typical dishwashing gloves are approximately 15 to 20 mils thick, and surgical latex gloves are on the order of 3 to 8 mils thick.

- A final consideration in glove selection is an individual’s sensitivity to the materials and chemicals used in the manufacture of gloves. Some people have allergic reactions to natural rubber proteins in latex, glove powder (used for absorbing perspiration), or other chemical constituents, such as rubber accelerators (carbamates, thiurams, and mercaptobenzothiazole).

- Chemical-Resistance Charts and Glove-Selection Databases

- Objective data (such as chemical-resistance charts and selection databases) must be used to choose the appropriate glove. Chemical-resistance charts are available from the CHSP manager (or directly from the manufacturer).

- The Web sites listed below are recommended for selecting chemically resistant gloves. Some allow different ways to search for the most appropriate glove. Searching by chemical name will produce a list of gloves that protect against a particular agent. Searching by glove type will give a list of chemicals for which a specific glove was tested. Glove thickness is normally listed or is available by clicking on the link for the recommended glove.

- Glove Manufacturer Web Sites:

- Independent Glove Selection Web Sites:

- Michigan State University Chemical-Resistant Glove Guide

- Oklahoma State University Chemical Guide and Permeation Tables

- An EHS Health and Safety Representative may also be contacted for assistance in glove selection.

- Eye and Face Protection. This section discusses the uses and limitations of safety glasses, chemical goggles, and face shields. The type of protection selected must be based on risk — i.e., the degree of hazard (severity) and the likelihood of an accident occurring (probability).

- All eye and face protection must meet the Basic Impact Testing Requirements of the latest version of the American National Standard for Occupational and Educational Personal Eye and Face Protection Devices ANSI Z87.1. (These eye-protection devices are marked “Z87.”)

- Where there is a possibility of a hazard from flying particles, the eye protection must meet the High Impact Testing Requirements of Z87.1 (this eye protection is marked “Z87+”).

- An EHS Health and Safety Representative may be consulted to provide guidance in selecting the proper protection.

- Safety Glasses

- Safety glasses with side shields are required to be worn by individuals while handling or using chemicals. They must meet the basic impact-resistance provisions of ANSI Z87.1.

- Safety glasses are the minimum protection required when handling chemicals. Safety glasses must be supplemented with goggles and/or face shields when there is a greater risk of exposure to chemical splashes or flying particles (e.g., when pouring or mixing chemicals or cryogens).

- Contact lenses may be worn in work areas. However, contact lenses do not provide eye protection. Safety glasses or goggles must be worn by people who use contact lenses when chemicals are being handled.

- Cover Goggles

- Cover goggles are required for operations where there is a greater risk of exposure to chemicals and to flying particles. Furthermore, they are required for activities producing airborne eye irritants including gases, vapors, fumes, dusts, and mists. Safety glasses provide no protection against eye irritants.

- Cover goggles are available in several varieties including:

- Direct-vented. These allow airflow for comfort and to reduce fogging. Generally, direct-vented goggles are inappropriate for liquid chemical use because the vent ports may allow splashed liquids to pass through. Moreover, they provide no protection against airborne eye irritants (gases, vapors, fumes, dusts, and mists).

- Indirect-vented. These allow airflow for comfort and to reduce fogging. These are appropriate for liquid chemical use and will protect the eyes from splashes. However they will not guard against irritating gases, vapors, fumes, dusts, and mists.

- Non-vented. These have no vents and are required for operations that produce airborne irritating gases, vapors, fumes, dusts, and mists. They also protect against chemical splashes to the eyes.

- Face Shields

- Face shields protect the entire face and are required for operations that present a high likelihood of exposure to flying particles or splashes from liquid chemicals or cryogenic fluids.

- Face shields must be worn in conjunction with safety glasses or chemical goggles, because face shields can be lifted up during use, exposing the eyes to hazards.

- Respirators

- Respirators should not be needed in most laboratory and shop settings. However, if engineering, work practices, and administrative controls are not adequate to minimize an airborne chemical hazard, respiratory protection is required.

- Use of respirators requires a hazard evaluation conducted by an EHS Health and Safety Representative. All respirator users must be medically qualified, trained, and fit-tested to wear respiratory protection equipment.

- An EHS Health and Safety Representative must approve procurement of respirators.

- Any questions regarding the need for or use of respirators should be directed to an EHS Health and Safety Representative. Berkeley Lab respirator policy may be found in the EH&S Chapter 44, Respiratory Protection program.

Work Process J. Work Practice Controls

Work practice controls include pre-planning work, practicing good housekeeping, maintaining personal hygiene to minimize exposure to hazardous materials, and using common sense. Work practice controls must be used regardless of the type of hazardous material handled. This is not accomplished through the WPC process alone. This evaluation should be performed prior to the start of any task. The first three steps of the Integrated Safety Management (ISM) process should be employed prior to the initiation of work: Define the scope of your work; Identify all hazards associated with the work; Identify the controls necessary to mitigate those hazards.

- Work Planning

- Pre-plan work: Stage tools, equipment, and materials in advance of the activity to be performed.

- Establish designated areas for work involving particularly hazardous substances.

- Stay upwind or use exhaust ventilation for operations that emit vapors, gases, fumes, dusts, mists, or aerosols.

- Limit the amount of hazardous materials procured, used, and stored to the minimum needed for an operation.

- Keep drip pans, secondary containment and cleanup materials readily available.

- Be familiar with the use, limitations, and location of emergency equipment such as emergency eyewashes, safety showers, fire alarms, exits, and fire extinguishers.

- Keep containers covered when not being used.

- Remove jewelry to prevent contact with electrical sources and chemicals and from catching on laboratory or shop equipment.

- Confine long hair and loose clothing when working in the laboratory/shop.

- Housekeeping

- Keep work areas clean and free of obstructions. Clean the work area at the completion of an operation or at the end of the day.

- Wipe drips and residues from containers of hazardous materials. Skin contact with residues may cause dermal absorption, chemical burns, skin irritation, and possible accidental ingestion as a result of hand-to-mouth transfer.

- Clean surfaces (counter tops, bench tops, fume hoods, and floors) of all drips and residues.

- Clean spilled chemicals immediately, and dispose of all wastes properly. Spill response is discussed later. Chemical wastes must be disposed of in accordance with the ES&H Manual Waste Management program.

- Maintain access to exits, emergency equipment, and other control equipment. Do not use stairways and hallways as storage areas. Store equipment and chemicals properly, and avoid clutter.

- Personal Hygiene

- After handling chemicals, wash hands with soap and water before leaving the laboratory/shop area and prior to breaks and consumption of food/beverages.

- Always remove gloves before touching common use items such as phones, doorknobs, and computers. This will prevent contamination of unprotected individuals.

- Food, Beverage, Cosmetics, and Medicine in Technical Areas

- Food and beverages (including water, gum, and medicines) may not be consumed or stored in technical areas. Exceptions may be granted in accordance with the procedure described in ES&H Manual Personal Protective Equipment (PPE) program, Appendix A, PPE and Food/Drink Requirements and Responsibilities Table.

- Cosmetics, ointments, skin cream, and similar items may not be applied or stored in technical areas.

- See Work Process K.1.b, Refrigerators and Freezers Used for Hazardous Material Storage, for requirements regarding food storage in refrigerators.

- Do not use laboratory glassware or utensils to prepare or consume food or beverages.

- Use of Glassware

- Never use mouth suction to pipette chemicals or to start a siphon; use mechanical means, a pipette bulb, or an aspirator.

- Use adequate hand protection (e.g., proper gloves) when inserting glass tubing into rubber stoppers or corks or when placing rubber tubing on glass hose connections. Tubing should be fire-polished or rounded and lubricated, and hands should be held close together to limit movement of glass should fracture occur. Plastic or metal connectors should be used whenever possible.

- Do not attempt glassblowing operations unless proper annealing facilities are available.