Contents

Approved by Kurt Ettinger

Revised 6/24

13.1 Policy

13.2 Scope

13.3 Applicability

13.4 Exceptions

13.5 Roles and Responsibilities

13.6 Acronyms and Definitions

13.7 Required Work Processes

- Work Process A. General Requirements

- Emergency Response

- Work Planning and Control

- Training

- Procurement

- Installation and Set Up

- Storage, Use and Handling

- Outdoor Locations

- Transportation

- End-of-Life: Return and Disposal

- Work Process B. Flammable Gases

- Work Process C. Pyrophoric Gases

- Work Process D. Corrosive and Health-Hazard Gases (Toxic Gases)

13.8 Source Requirements

13.9 Reference Documents

13.10 Appendices

- Appendix A. Gas-Detection System Requirements

- Appendix B. Specific Health-Hazard Gas Classifications

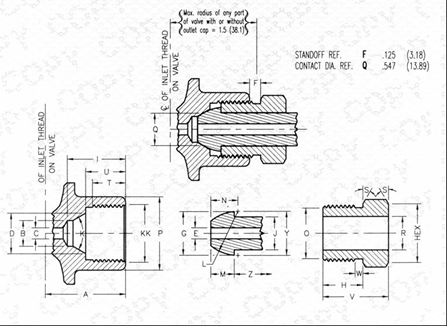

- Appendix C. Gas System Component Information

- Appendix D. Additional Information: Mixed Gases, Toxic Gases

Note:

🚩🚩 Denotes a new section

🚩 Denotes the beginning of changed text within a section

🛑 Denotes the end of changed text within a section

____________________

13.1 Policy

Berkeley Lab’s Gas Safety Program identifies precautions to prevent injuries, property damage, and disruption to operations caused by leaks of compressed gas and over-pressurizations. Precautions prevent the following types of accidents and injuries:

- Explosions and injuries caused by flying objects accelerated by an explosion or pressure release

- Fires and injuries caused by flammable gas ignition

- Injuries caused by inhalation of toxic or asphyxiating gases

13.2 Scope

This program applies to the storage, use, and handling of gases in pressurized portable containers (e.g. compressed gas cylinders) and gas systems. The primary focus of this program is on single-gas uses and systems.

Additional requirements apply to:

- Pressure and cryogenic systems, covered under Chapter 7 Pressure System Safety and Chapter 29 Safe Handling of Cryogenic Liquids

- Vehicular transportation of compressed gases, as described in the EHS web page on transportation of hazardous materials

- Large compressed-gas facilities, storage areas, or use areas (per fire codes)

13.3 Applicability

All Berkeley Lab employees, affiliates, and subcontractors who order, handle, or dispose of gases.

13.4 Exceptions

None

13.5 Roles and Responsibilities

|

Role |

Responsibilities |

|

Principal Investigator/Supervisor |

The principal investigator or gas-use supervisor has primary responsibility for gas-use safety and implementation of all provisions of this chapter, including:

|

|

EHS — Research Support Team and/or Gas Safety SME |

Provides an Environment, Health, and Safety (EHS) hazard evaluation and code compliance coordination role related to fire, life-safety, pressure, health, and oxygen-deficiency gas hazards that includes:

|

|

EHS- Waste Management |

|

|

Facilities Department — Maintenance & Operations |

|

|

Procurement Department |

|

|

Security and Emergency Services Division (SES) – Fire Department |

|

|

Security and Emergency Services Division (SES) – Fire Protection |

|

|

Security and Emergency Services Division (SES) – Emergency Management |

|

|

Security and Emergency Services Division (SES) – Site Operations Center (SOC) |

|

13.6 Acronyms and Definitions

|

Term |

Definition |

|

CFC |

California Fire Code |

|

CMS |

|

|

Compressed gas |

A material or mixture of materials which:

|

|

Control area |

A space within a building where quantities of hazardous materials not exceeding the maximum allowable quantities per control area are stored, dispensed, used or handled. The space is bounded by not less than a one-hour fire-resistive assembly. |

|

Corrosive gas |

A gas that can cause visible destruction of, or irreversible alterations in, living tissue (e.g., skin, eyes, or respiratory system) by chemical action |

|

DBT |

Design Basis Threat – Per the requirements of DOE O 470.3C, DBT is a description of the type, composition, and capabilities of an adversary, against which a security system is designed to protect. LBNL uses the DBT as a basis for designing safeguards systems to protect against acts of hazardous material sabotage and to prevent the theft of security assets. These assets require additional security controls and authorizations for use. |

|

DOT |

U.S. Department of Transportation |

|

EPHA |

Emergency Planning Hazard Assessment – Per the requirements in DOE O 151.1D, an EPHA is a quantitative analysis identifying hazards and the potential consequences from unplanned releases of (or loss of control over) hazardous materials, using accepted assessment techniques. |

|

Exhausted enclosure |

An appliance or piece of equipment that consists of a top, a back, and two sides providing a means of containing, capturing, and exhausting gases, fumes, vapors and mists. Such enclosures include laboratory hoods, exhaust fume hoods, and similar appliances and equipment. Rooms or areas provided with general ventilation are not exhausted enclosures. |

|

EFV |

Excess Flow Valve |

|

Flammable gas |

A material which is a gas at 68O Fahrenheit (F) or less and 14.7 pounds per square inch, actual (psia) of pressure which:

|

|

Gas cabinet |

A fully enclosed, ventilated, noncombustible enclosure used to provide an isolated environment for compressed gas cylinders that are in storage or use. Doors and access ports for exchanging cylinders and accessing pressure-regulating controls are allowed to be included as part of the cabinet. |

|

Hazardous gas |

A gas that is included in one or more of the following hazard categories: corrosive, flammable, health hazard, oxidizer, pyrophoric, reactive, highly toxic, or toxic |

|

Hazardous-gas detection system |

A fixed system used to detect the presence of hazardous gas at potentially unsafe levels |

|

Health hazard (gas classification) |

A classification that indicates statistically significant evidence that acute or chronic health effects are capable of occurring in a person exposed to this chemical. The term “health hazard” includes gases that are toxic, highly toxic, and corrosive. See Work Process D, Health-Hazard Gases. |

|

Immediately Dangerous to Life and Health (IDLH) |

The concentration of air-borne contaminants that poses a threat of death, immediate or delayed permanent adverse health effects, or effects that could prevent escape from such an environment. This contaminant concentration level is established by the National Institute of Occupational Safety and Health (NIOSH) based on both toxicity and flammability. |

|

Liquefied gas |

A liquid contained in a compressed gas cylinder that has a vapor pressure exceeding 276 kilopascals (KPa) at 38° Celsius (C) (40 psi at 100°F) |

|

Lower Flammability Limit (LFL) |

The minimum concentration of vapor in air at which propagation of flame will occur in the presence of an ignition source. The LFL is sometimes referred to as the lower explosive limit (LEL). |

|

Maximum Allowable Quantity (MAQ) |

The maximum amount of a hazardous material allowed to be stored or used within a control area inside a building or in an outdoor control area. |

|

NFPA |

National Fire Protection Association |

|

NTP |

Normal temperature and pressure: 1 atmosphere (atm) and 20°C. (Compare with STP below.) |

|

Oxidizing gas |

A gas that can support and accelerate combustion of other materials more than air does |

|

Oxygen deficiency |

A condition that occurs when a breathable atmosphere contains less than 19.5% oxygen. (Normal air contains 20.9% oxygen.) |

|

Permissible Exposure Limit (PEL) and Threshold Limit Value (TLV) |

Airborne exposure limits established for particular chemicals by the Occupational Safety and Health Administration (Federal and Cal/OSHA) and the American Conference of Governmental Industrial Hygienists (ACGIH), respectively. DOE requires that employee exposures not exceed PELs or TLVs. |

|

Pyrophoric gases |

Gases with an auto-ignition temperature in air at or below 54°C (130°F). Specific gases may not ignite in all circumstances or may explosively decompose. |

|

RFID |

Radio frequency identification. RFID tags are used for compressed gas and hazardous chemical inventory tracking at LBNL. |

|

RFO |

Restricted Flow Orifice |

|

Safety Note |

A document that is a record of engineering calculations or tests on specific equipment. A Safety Note may also specify operational requirements addressed in a WPC Activity or in operating instructions. See Chapter 7 Pressure Safety. |

|

STP |

Standard temperature and pressure- 1 atm and 0°C (Compare with NTP, above.) |

Time-Weighted Average (TWA), Short-Term Exposure Limit (STEL), and Ceiling (C) standards are summarized as follows:

| Organizations and Standards | Work Exposure Duration |

|---|---|

| Cal/OSHA PEL-TWA and ACGIH TLV-TWA | 8-hour shift and 40-hour week |

| Cal/OSHA PEL-STEL and ACGIH TLV-STEL | 15 minutes |

| Cal/OSHA PEL-C and ACGIH TLV-C | Any point in time |

13.7 Required Work Processes

Work Process A. General Requirements

Work Process B. Flammable Gases

Work Process C. Pyrophoric Gases

Work Process D. Corrosive and Health-Hazard Gases (Toxic Gases)

Work Process A. General Requirements

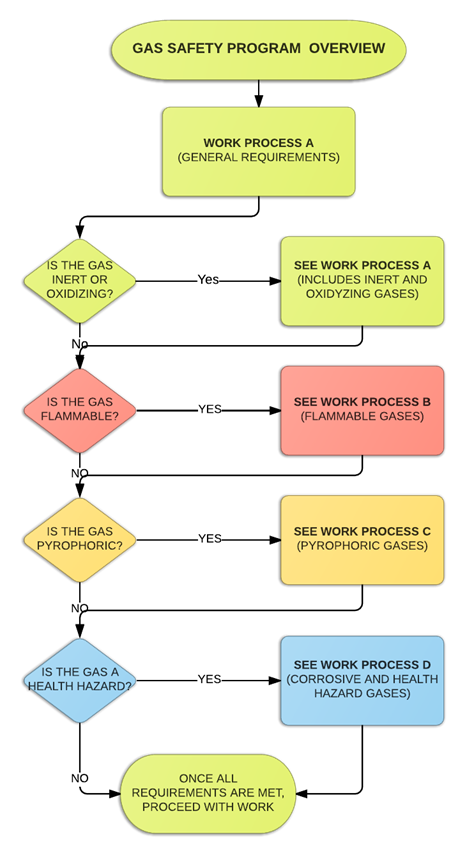

- Scope. The requirements in this work process apply to all compressed gases and compressed gas systems. This section also contains the specific requirements pertaining to inert and oxidizing gases. A flow chart of all work processes and gas types follows:

- Emergency Response

- When a gas leak that poses an immediate threat such as fire, explosion, or health hazard:

- If the leaking gas is flammable and it is safe to do so, turn ignition sources in the vicinity of the leak off.

- Evacuate the area immediately.

- Call 911

- When a gas leak that poses an immediate threat such as fire, explosion, or health hazard:

- Work Planning and Control

- The use of compressed gases must be authorized using the LBNL Work Planning Control (WPC) Activity Manager database.

- The Work Planning and Control website includes tools and information for documenting research work activities. The principal investigator / supervisor must:

- Ensure the work is properly authorized

- Ensure that workers working with compressed gases are authorized on appropriate work activities before work begins

- Training

- Personnel must complete the following Berkeley Lab courses and training in accordance with the hazards posed by their work activities:

- 🚩Working Safely with Compressed Gas (EHS0103) and Pressure Safety Awareness for Research (EHS0171)🛑 provide an overview of the safety issues and requirements for the use of pressure systems, and must be completed by anyone who works with compressed gas and pressure systems.

- Chemical Hygiene and Safety Course (EHS0348) provides information on the hazards and controls associated with chemicals that may be encountered in a research laboratory setting, and must be completed by personnel who handle or use hazardous gases.

- Specialized on-the-job training on the hazard and safety procedures for each hazardous gas-use operation must be provided by the supervisor, and must include a review of the related WPC Activity.

- Additional requirements apply to personnel who design or assemble pressure systems as described in Chapter 7 Pressure Safety Program.

- Personnel must complete the following Berkeley Lab courses and training in accordance with the hazards posed by their work activities:

- Procurement

- The following requirements apply when procuring compressed gases:

- Maximum Allowable Quantity (MAQ): To minimize risk, the fire code establishes limits on the MAQ of compressed gas that can be stored in a “control area,” which can be defined as an entire building, or a floor or section of a building. MAQs per control area are documented in Chapter 12 Fire Prevention and Protection.

- Maximum Cylinder Size. Cylinders of flammable and oxidizing gases in excess of 250 standard cubic feet (SCF) at normal temperature and pressure (NTP) are not permitted for indoor use per NFPA 55, Compressed Gases and Cryogenic Fluids Code.

- CMS Approval: All compressed gas cylinders are considered hazardous for the purposes of CMS inventory tracking, hazardous material screening, and approval (when required). Refer to ES&H Manual Chapter 45, Work Process B, Chemical and Equipment Procurement for specific requirements.

- Before purchasing gas in larger quantities than usual, or gas that poses a new physical or health hazards (i.e. toxic gases), consult with the Gas Safety program subject matter expert or Security and Emergency Services to determine if MAQs will be exceeded or if approval is required.

- The following requirements apply when procuring compressed gases:

- Installation and Set Up

- Many safety considerations for installing and setting up a gas system are documented below, but additional requirements may apply as prescribed in the governing regulations for a particular gas type. Gas systems that pose a pressure hazard must also comply with requirements documented in Chapter 7 Pressure Safety.

- For assistance with installing, inspecting, repairing and maintaining regulators and related gas system components, contact Facilities (ext 6274) or place a work order request through the Facilities Work Request Center.

- Minimum requirements for installation and set-up include:

- Safety Shower and Eyewash. An approved safety shower and eyewash must be maintained at locations where corrosive, eye-irritating, or skin/eye-toxic gases are stored or used. The shower or eyewash station must be within 10 seconds or 30 meters (m) (100 feet [ft]), whichever is less.

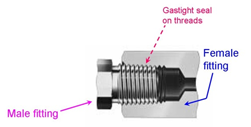

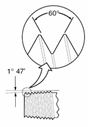

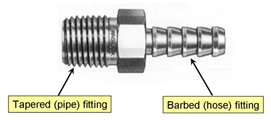

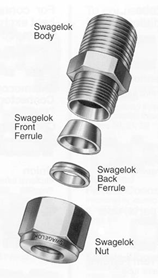

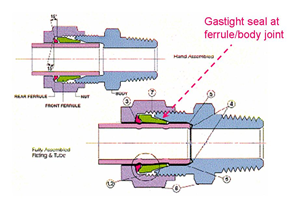

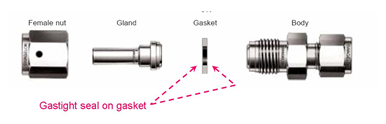

- Pipe and Component Compatibility and Ratings. Gas pipes, valves, fittings, regulators, and related components must be constructed of materials compatible with the gases to be contained and must be rated for the service. More information on tubing and fittings can be found in Work Process B, Work Process C, Work Process D, and Appendix C, Gas System Components Information. Compatibility charts for certain gas are provided by the following gas providers:

- Pipe Labeling in Research and Technical Areas

- At the minimum, each research gas plumbing system* must be labeled so that the following points are clearly and uniquely identified:

- source;

- point(s) of use;

- critical shut-off valve(s);

- points where plumbing becomes obscured by walls, ceilings, fixtures, etc.

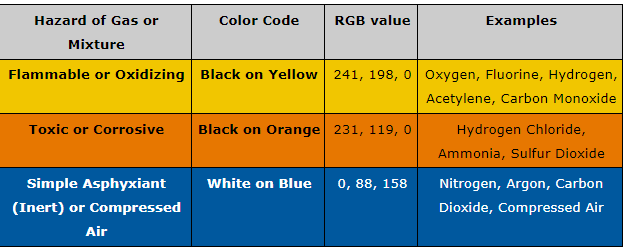

- These labels must include the following information:

- the identity of the gas or a specific description of the mixture, if possible

- an identifier unique to that line if the gas/mixture is intended to be variable, e.g., “Line B”

- a direction of flow arrow, or arrows in both directions if the flow is intended to change direction

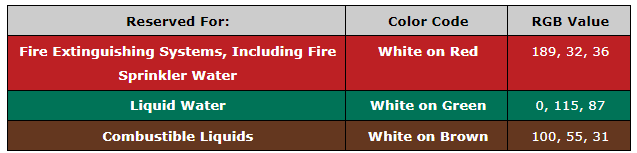

- a hazard color code dictated by ANSI/ASME A13.1 chosen based on the properties of the most hazardous gas or mixture that is intended to be transported in that line (see Table 13.1)

Note: Although additional labels are not prohibited, such labels must not use any reserved color code per ANSI/ASME A13.1 that does not reflect the actual contents of the plumbing (see Table 13.2 for reserved colors not applicable to research gas plumbing)

- Labels must be applied directly to the plumbing where practical; otherwise, labels may be applied near the plumbing such that each line can be clearly and uniquely identified.

- It is recommended that the label also bear the hazard classification of the gas/mixture where practical, especially for plumbing that is labeled with a naming scheme rather than specific contents. For example, “Line B – FLAMMABLE” or “Vent – TOXIC”.

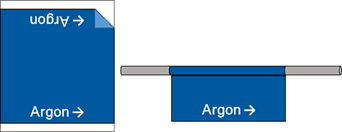

- Where plumbing outer diameter is too small or the tubing too flexible for practical application of traditional adhesive labels, the label may be applied as a flag or hanging tag, as in the following examples:

4” wide label tape, folded over small tube to create ~2” flag

Plastic sleeve with printed insert, zip-tied to small tube - EHS will provide ANSI/ASME A13.1 compliant adhesive labels upon request in sizes ranging from 0.5” to 4” wide, or sets of plastic sleeves, printed inserts, and zip ties.

- Exemptions: Due to the complicated nature of research work, this policy may not be practical for all research gas plumbing systems. See ES&H Manual Chapter 1, Work Process B for more information on obtaining exemptions.

* “Research gas plumbing system” for the purposes of this policy is defined as a system that transports and/or controls the transport of a gas or mixture of gases from a source to its point of use, and is not in itself an integrated part of a piece of equipment or laboratory apparatus (e.g., a tube furnace, glove box, or Schlenk line).

Table 13.1 ASME/ANSI A13.1 Hazard Color Codes for Research Gas Plumbing

Table 13.2 Other ASME/ANSI A13.1 Reserved Color Codes

- At the minimum, each research gas plumbing system* must be labeled so that the following points are clearly and uniquely identified:

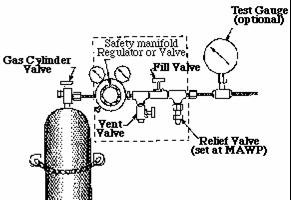

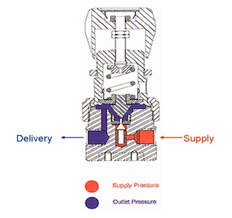

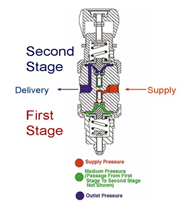

- Pressure Regulator. Gas system pressure must be reduced through a regulator mounted to the cylinder valve outlet or to a manifold. A regulator of the approved type and design for the specific gas and cylinder combination must be used.

- Inspect the regulator before installation to ensure that it is the correct one for the particular application and that it is in safe working condition.

- Oxygen regulators must be labeled for oxygen service, and used regulators reapplied to oxygen service must be degreased.

- Note: a regulator is not a safety device and could fail, even at first use. It is essential that the regulator and gas system components are protected by some form of pressure relief device such as a pressure relief valve or rupture disk. See Chapter 7 Pressure Safety for more information.

- Regulators must never be altered or repaired by unauthorized personnel.

- More information on regulators can be found in Appendix C, Gas System Components Information.

- Backflow Prevention

- Backflow prevention devices such as check valves must be provided when the backflow of materials could create a hazardous condition.

- Flashback arrestors are required when fuel and oxidizing gases are connected to a torch or other equipment where gases mix. Check valves will not stop a flashback.

- Shutoff Valves. Required emergency shutoff valves must be:

- Easily accessible, the valve location must be identified by means of a sign, and the valve must be labeled with the gas name or function. Exception: Gas cylinder valves do not need to be identified.

- An emergency gas shutoff valve must be located at the process equipment that uses hazardous gas when this equipment is in a different room than the source gas cylinder.

- Accidental Flow Control. Excess flow valves (EFVs) or restrictive flow orifices (RFOs) are recommended and may be required by this policy or by EHS to control accidental gas leaks or flows that could cause a fire, explosion, or health risk. See Work Process D for more detailed RFO requirements.

- Purge Gas

- When an inert gas source is used to purge hazardous gas from gas lines that use gases of different hazard categories, a separate purge supply must be used for each category of hazardous gas.

- It is preferable to have a separate purge cylinder for each hazardous gas cylinder in use.

- Backflow prevention devices must be installed between the purge gas supply and the hazardous gas system.

- House nitrogen cannot be used as a purge gas.

- Vacuum Pumps. The type of vacuum-pump oil to be used with gases and chemicals must be analyzed for its compatibility with those gases and chemicals. Hydrocarbon oil should not be used with an oxidizer or with pyrophoric gases. Inert oils should be used instead. Pumps must have a pressure relief or shutdown device that prevents the pump from bursting if a line becomes plugged. Oil drip pans should be placed under all pump and oil filter assemblies. For more information see Chapter 7 Pressure Safety.

- Ventilation

- General Ventilation Requirements

- The exhaust ventilation system for a hazardous gas area and hazardous gas use must be installed in accordance with the California Fire Code and California Mechanical Code.

- General area mechanical ventilation for hazardous gas stored and used indoors must be 0.005 cubic meters per second (m3/s) per square meter (one cubic feet per minute [cfm] per square foot) of floor area or greater.

- The ventilation system must operate continuously.

- Exhausted Enclosures – General Enclosure Requirements

- A gas cabinet or fume hood must be used when exhausted enclosures are required for the storage or use of a hazardous gas cylinder.

- Each fume hood or gas cabinet that contains one or more hazardous-gas cylinders must be posted with a sign that identifies the name of the gases and their hazard categories.

- Exhausted enclosures for hazardous gases must be constructed of noncombustible materials.

- General Ventilation Requirements

- Gas Cabinets

- Gas cabinets must meet current industry and regulatory specifications, which typically include the following:

- Constructed of not less than 12 gauge (2.5 mm or 0.097 in) steel and coated to prevent corrosion

- Provided with a self-closing and self-latching cylinder access door

- Provided with a noncombustible safety window (6.4 mm or 0.25 in) wire-reinforced safety glass

- Provided with self-closing access port(s) or windows of sufficient size that allow hand access to equipment controls

- Provided with makeup air inlets that allow air circulation throughout the cabinet when the access port(s) or windows are closed

- Provided with an approved fire sprinkler

- Limited to a maximum of three gas cylinders

- Provided with exhaust ventilation that ensures the cabinet is at negative pressure in relation to the surrounding area

- An average velocity of air flow at the face of open access ports or windows of 1 to 1.5 m/s (200 to 300 fpm) with a minimum of 0.75 m/s (150 fpm) at any measurement point.

- Gas cabinets must meet current industry and regulatory specifications, which typically include the following:

- Exhaust Duct Systems and Connections

- Exhaust systems must be constructed to current building code, fire code, and ACGIH Industrial Ventilation Manual requirements. For example:

- Exhaust ducts for hazardous gases must be constructed of noncombustible materials, constructed of compatible materials (or have interior coatings), and must be sealed and seismically braced.

- Exhaust ducts must maintain negative pressure and required flow rates.

- The following purge and exhaust systems ancillary to the use of hazardous gas must be connected to the exhaust duct system in an approved manner:

- All lines or ducts carrying purged hazardous gas emissions (e.g., pipe vents) or exhausted hazardous gas emissions (e.g., vacuum pump lines)

- Exhausted enclosures, gas cabinets, and lab hoods.

- Exhaust systems must be constructed to current building code, fire code, and ACGIH Industrial Ventilation Manual requirements. For example:

- Ventilation Monitoring

- All exhausted enclosures must have a ventilation monitor that measures duct or enclosure exhaust performance and displays a quantitative readout easily visible to the gas user (e.g., magnehelic or better).

- When ventilation monitoring is required, the monitor must have local audible and visual alarms that activate when the exhaust flow decreases to 70% to 80% of the required air flow.

- Gas Detection

- General Detection Requirements

- Gas-detection controls must be used when highly toxic, toxic, flammable, or oxygen-deficiency leak risks cannot be adequately controlled by other means or when required by codes.

- Gas-detection controls must not be used in place of proper primary controls (e.g., approved gas lines) and secondary controls (e.g., ventilation and ventilation monitoring). Ventilation monitoring interlocked with automatic gas shutdown at the gas source may also be required.

- Requirements for flammable and health-hazard gas-detection procedures are presented Work Process B, Flammable Gases, and Work Process D, Corrosive and Health-Hazard Gases. Requirements for oxygen deficiency detection procedures are presented below. When gas detection procedures are required, Appendix A is used to determine gas detector system maintenance, selection, installation. Appendix A also includes auditing and other requirements for gas detection systems.

- Oxygen-Deficiency Detection

- Oxygen deficiency detection controls may be needed to detect a lack of breathable air in a space that could be occupied. Oxygen deficiency may result when there is inadequate ventilation and/or displacement of air by a gas or process byproduct. Examples at LBNL include the use of house nitrogen lines in small or inadequately vented spaces or in spaces where oxygen is purposely removed for research purposes. Guidelines for oxygen deficiency detection must be developed on a case-specific and hazard basis through a WPC review or risk assessment conducted using oxygen deficiency hazard calculations. Oxygen-deficiency detectors are generally not recommended when engineering controls (e.g., ventilation) can be used to control the hazard.

- A work space that may be oxygen deficient and have limited personnel access and egress meets the definition of a “confined space” and must meet all the requirements of Chapter 34 Confined Spaces. Portable oxygen detectors – in place of fixed-in-place detectors – are usually sufficient for confined spaces.

- General Detection Requirements

- Electrical Systems

- Electrical equipment and wiring must be installed in accordance with the National Electrical Code. Gas piping and containers must not be designed or placed where they can become part of the electrical circuit or used for grounding.

- Required ventilation and control systems must be connected to a standby or emergency source of power to automatically supply electricity in the event of loss of power from the primary source. Exception: when standby power is not available in the building and the gas quantities are below the amounts allowed by the California Fire Code (CFC). Emergency power is required for CFC highly toxic gases in quantities greater than the MAQ.

- When standby or emergency power is not provided for a hazardous gas system that provides primary control against the development of a hazardous condition, loss of system power must activate automatic gas shutoff. For example: an exhaust duct blower that provides exhaust ventilation for flammable or health-hazard gas process effluents that continue to be generated after power is lost.

- Gas Flow System

- Pressure Safety. Compressed gas systems must be designed and installed in accordance with the requirements of Chapter 7 Pressure Safety except for the following:

- Inert-gas systems to 1 megapascal (MPa) gauge (150 psig) with a total stored energy of not more than 100 kilojoules (kJ) (75,000 ft-lb)

- Simple flow system with a standard pressure regulator, with pressure-relief devices set to no more than 1 MPa gauge (150 psig) and with no components rated for a working pressure less than 1 MPa gauge

- Under no circumstances may any gas be used without a standard pressure regulator that is rated for the service and compatible with the gas.

- Depending on the pressure rating of the system, a Safety Note may be required. Systems must be constructed in accordance with the requirements of Chapter 7 Pressure Safety.

- All pressurized hazardous gas system connections must be checked for leaks on new gas systems and after reconnection of any fitting.

- Pressure Safety. Compressed gas systems must be designed and installed in accordance with the requirements of Chapter 7 Pressure Safety except for the following:

- Storage, Use and Handling

- Many of the following items should be addressed during installation and set-up. Regardless, storage, use and handling of compressed gases must meet the following requirements:

- Chemical Management System. To control quantities of gases at specific locations, including outdoor storage areas, each storage location must be identified and an itemized inventory must be maintained for each location in Berkeley Lab’s Chemical Management System (CMS). Refer to ES&H Manual Chapter 45, Work Process D. Berkeley Lab Chemical Inventory for additional requirements.

- Work Planning & Control. Gas use must be authorized through WPC. Risk Level 3 gas hazards require the highest level of control. The inventory list of Risk Level 3 gas hazards (e.g. corrosive, pyrophoric, toxic) to be stored and used for an Activity, must be included in the WPC hazard itemization table(s) in order to determine applicable controls, including Physical Security Program requirements for materials/quantities that fall under the hazardous materials management policy. All locations of storage and use must be added to the Activity to ensure they are authorized.

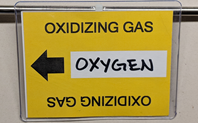

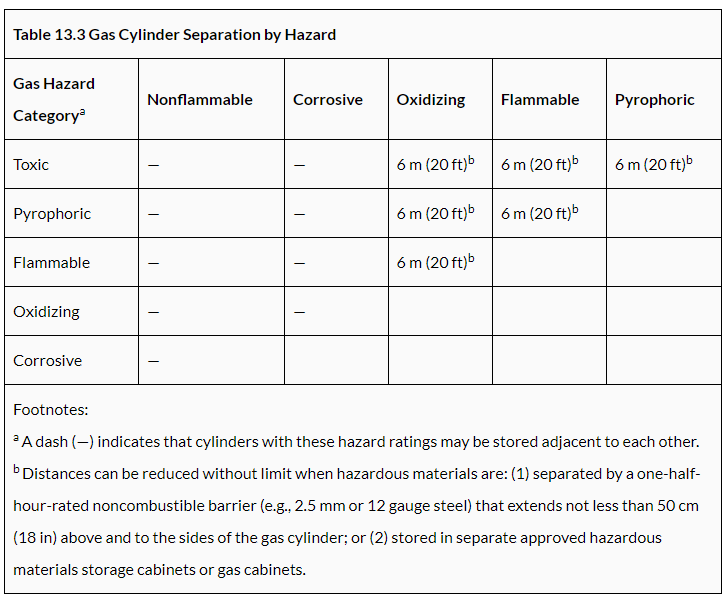

- Hazardous Materials Separation. Hazardous gases must be separated from incompatible hazardous materials by distance (as noted in Table 13.3 below), barriers, or cabinets. When a gas is classified in more than one category, all compatibilities must be considered and the most stringent separation used. Non-hazardous gases (e.g., inerts) may be stored along with gases in any hazard category. When gas cylinders must be separated into hazard categories, each category area will be posted with a hazard category sign. Incompatible materials must never be stored in the same gas cabinet or exhausted enclosure.

See Appendix B for hazard categories of specific health hazard gases.

Table 13.3 Gas Cylinder Separation by Hazard

- Cylinder Securing. Gas cylinders must be secured to prevent falling due to accidental contact, vibration, or earthquake in one of the following ways:

- By a noncombustible, two-point restraint system (e.g. chains) that secures the cylinder at the top and bottom one-third portions. Exception: A cylinder less than 1 m (3 ft) tall requires only one restraining point. Note: LBNL follows the UC Lab Design Guide (2nd Edition), which specifies non-combustible restraints for cylinders. While readily available webbing-style strapping systems may appear to be a good selection for securing cylinders, many of these systems are constructed of combustible materials (e.g. nylon) and would not meet the non-combustible requirements.

- By a noncombustible rack, framework, cabinet, approved strapping device, secured cylinder cart, or other assembly that prevents the cylinder from falling.

- Cylinder Position. Gas cylinders must be stored in a “valve end up” upright position, including conditions in which the cylinder is inclined as much as 45 degrees from the vertical. Exceptions include cylinders designed for use in a horizontal position and cylinders with non-liquefied compressed gas that have a water volume less than 5 Liters (0.18 cf or 1.3 gal).

- Cylinder Valves, Caps, and Plugs

- Gas cylinders designed to have valve-protection caps and valve-outlet caps and plugs must have these devices in place. Exceptions: when the cylinder is in use, connected for use, or being serviced.

- Gas cylinder valves must have a manual shutoff valve, hand wheel, spindle key, or other approved control handle on the valve stem while the cylinder is in use. Cylinder valves should be opened slowly, and should be kept closed when gas is not in use. A fully open “tight” valve may be mistakenly assumed to be closed, so when opening a valve, turn it back a quarter turn from fully open to prevent this phenomena.

- A quick connect shall not be used in place of a shutoff valve. Each point of use shall have an accessible manual shutoff valve.

- Cylinder Changing

- Two people must be present during hazardous gas purge and cylinder change procedures.

- Reconnected gas fittings must be checked for leaks using a leak-detection fluid or other approved method.

- Exits and Lighting

- Storage or use of gas cylinders in exit corridors are prohibited.

- Hazardous gases must be located away from exit routes and doors, unless located in gas cabinets.

- Emergency lighting requirements can be found in Chapter 12 Fire Prevention and Protection.

- Area Signs. Every entrance to an area where hazardous gases are used or stored must be posted with visible and durable gas hazard identification signs. Hazardous-gas exterior storage and use areas must have signs that prohibit smoking within 8 m (25 ft).

- Storage/Use. Cylinders that are not necessary for current laboratory requirements shall be stored outside the laboratory unit in accordance with NFPA 45, with the exception of nominal 0.5 kg (1 lb) propane cylinders made for consumer use. A compressed gas cylinder is considered to be “in use” if it is:

- Connected through a regulator to deliver gas to a laboratory operation, or

- Connected to a manifold being used to deliver gas to a laboratory operation, or

- A single cylinder secured alongside the cylinder described in 1 and 2 above as the reserve cylinder. Note: There is a maximum of one reserve cylinder for each cylinder connected for use as described in 1 and 2 above.

- Liquefied Gases and Eductor Tubes. Compressed liquefied gases must be used and stored in an upright position. Most compressed liquefied gas cylinders are set up to dispense the gaseous portion of the product from the cylinder. Rarely, an Eductor tube (aka: Dip tube) is available in the cylinder to extract the pressurized liquid product (e.g. carbon dioxide). When using a compressed liquefied gas, look for labeling that indicates the cylinder contains an Eductor tube, and will state – often in small lettering – “Caution Liquid Delivery.” This cylinder is equipped with an eductor tube. Do not connect to the liquid delivery valve if you require gas delivery.” Note: These cylinders (carbon dioxide) have been mistakenly ordered and set up for use at LBNL since they do not appear different from a standard cylinder setup for dispensing gaseous product. Eductor tubes are more commonly used for dispensing of cryogenic liquids. Safety procedures for cryogenic liquid use are in Chapter 29 Safe Handling of Cryogenic Liquids.

- Unauthorized Cylinder Modification or Use

- All labels, markings, and tags provided on the gas cylinder by the manufacturer must be maintained in good condition.

- Gas cylinder parts must not be modified, tampered with, obstructed, removed, repaired, or painted by the gas user.

- Many of the following items should be addressed during installation and set-up. Regardless, storage, use and handling of compressed gases must meet the following requirements:

- Outdoor Locations

- Exterior Locations. Exterior storage locations must be evaluated to determine the need for a weather protection canopy. A protection canopy would be required when the weather and/or other elements may adversely affect the integrity of the cylinders, cylinder components, or other equipment. If a canopy is erected it must be non-combustible.

- All outdoor storage areas must be protected from vehicle damage.

- Cylinders must not be placed on unpaved ground or on surfaces where water can accumulate.

- Storage and use of compressed gases shall be located not less than 50 ft (15 m) from air intakes.

- Outdoor storage areas must be inspected on a regularly scheduled basis by the area user(s).

- Combustible Materials Separation. Outdoor cylinder storage and use located in designated control areas must be kept clear of all weeds, grass, brush, and trash, as well as any other combustible materials, for a minimum distance of 7.5 m (25 ft) from all cylinders. Exception: An approved noncombustible barrier may be used instead. (See Hazardous Materials Separation, above).

- Cylinder Temperature Control. Compressed gas cylinders that have not been designed for use under elevated temperature conditions shall not be exposed to direct sunlight outdoors where ambient temperatures exceed 125°F (52°C).

- Approved storage locations. Toxic gases must NOT be stored in outdoor storage areas, unless specifically authorized through WPC.

- Exterior Locations. Exterior storage locations must be evaluated to determine the need for a weather protection canopy. A protection canopy would be required when the weather and/or other elements may adversely affect the integrity of the cylinders, cylinder components, or other equipment. If a canopy is erected it must be non-combustible.

- Transportation

- Use only standard DOT cylinders for transporting compressed gas. (A DOT cylinder is one that is designed, fabricated, tested, and marked [stamped] in accordance with regulations of DOT, Transport Canada [TC] Transportation of Dangerous Goods Regulations, or the ASME Boiler and Pressure Vessel Code, “Rules for the Construction of Unfired Pressure Vessels,” Section VIII.)

- Transport within a building or between adjoining buildings. Personnel trained to use compressed gases may use a standard cylinder cart to transport cylinders.

- Cylinders weighing 11 kg (25 lb) or less may be hand-carried, but it is preferable to use a cylinder cart.

- Multiple cylinders or cylinders heavier than 200 pounds (e.g. 6K cylinders) – get assistance from other trained personnel.

- Valve-protection caps and plugs must be in place during movement of cylinders. Lecture bottles and other cylinders without protective caps must be transported in standard shipping crates or an equivalent container.

- For more information on the safe handling of gas cylinders, see this video excerpt from the EHS Pressure and Compressed Gas Safety training (EHS0171).

- Transport between non-adjoining buildings. Berkeley Lab Facilities Transportation or approved Berkeley Lab gas supply subcontractors are authorized to move larger quantities these distances. Staff is authorized to personally move (self-transport) small quantities of most compressed gases by vehicle. See the EHS Transporting Hazardous Materials webpage for more information on authorized cylinders and procedures for self-transport.

- Cylinder Return or Disposal

- Empty Cylinders

- Leave residual pressure (i.e., typically 200 kPa or 30 psi) in the cylinder to prevent contamination of contents, and handle cylinders considered to be empty with the same precautions as cylinders filled with gas (since they should still contain residual gas and pressure).

- Empty gas cylinders must be labeled “Empty.”

- Do not remove RFID tags from toxic gas cylinders, even if they are empty.

- Keep the CMS status of toxic gas cylinders “active” to support accurate tracking until removal.

- Cylinder Return or Disposal

- For guidance on returning rental cylinders (e.g. vendor owned) or LBNL owned cylinders (e.g. lecture bottles), excluding toxic gas cylinders, contact your Division Safety Coordinator, the Gas Program subject matter expert (SME), or your Waste Generator Assistant.

- For disposal of unwanted toxic gas cylinders, enter the toxic gas cylinder(s) into the Toxic Gas Removal Request form or email toxic-gas@lbl.gov. See Work Process D. 5. Centralized Toxic Gas Receiving and Removal for more information.

- Empty Cylinders

Work Process B. Flammable Gases

- Scope

- In addition to the requirements in Work Process A, General Requirements – which apply to all compressed and hazardous gases – compressed and liquefied flammable gas must comply with the following codes and standards specific to their storage and use:

- CFC (current edition)

- NFPA 45, Standard on Fire Protection for Laboratories Using Chemicals (current edition)

- NFPA 55, Compressed Gases and Cryogenic Fluids Code (current edition)

- NFPA 50A, Standard for Gaseous Hydrogen Systems at Consumer Sites (current edition)

- For any design and construction requirements not specifically covered in this Work Process on the following topics, contact the indicated Berkeley Lab support team (in parentheses):

- Storage and use of flammable gas in quantities greater than the maximum allowable quantity, as specified in the codes and standards listed in the Fire Prevention and Protection Program, Appendix A. (SES, Fire Protection).

- Welding and cutting (SES, Fire Protection – contact for hot work permit). Requirements are specified in the following codes and standards:

- NFPA 51, Standard for the Design and Installation of Oxygen-Fuel Gas Systems for Welding, Cutting, and Allied Processes

- NFPA 51B, Standard for Fire Prevention During Welding, Cutting and Other Hot Work

- CFC, Chapter 35, Welding and Other Hot Work

- Dispensing of compressed liquefied flammable gas (Facilities or Engineering)

- Procurement and use of a hydrogen or other gas generating device (EHS Research Support Team)

- In addition to the requirements in Work Process A, General Requirements – which apply to all compressed and hazardous gases – compressed and liquefied flammable gas must comply with the following codes and standards specific to their storage and use:

- Piping and Components.

- Piping and related gas-flow components must be of compatible and noncombustible design and construction. Stainless steel pipe and fittings are recommended. Only compatible metal tubing shall be allowed for use with flammable or pyrophoric gases.

- If compatibility or contamination is of concern, non-metallic tubing may be used if it is contained within metallic tubing and if this use and configuration has been approved by the EHS Research Support Team and the SES Fire Protection team.

- Gas Cylinder Storage and Use.

- Interior storage and use

- Storage and use rooms must be of noncombustible construction.

- Fire codes restrict the total quantity of hazardous materials (e.g. flammable gases) allowed in a Fire Control Area. Fire Control Areas at LBL are generally categorized per section of floor, per floor, or per building, and it is important to understand applicable limits and properly manage and use flammable gases (and other hazardous materials) accordingly.

- More information about how Fire Control Areas are set up in your building may be obtained by contacting the Fire Marshal in SES.

- Single cylinders of flammable (and oxidizing) gas: the Fire Code states that no single cylinders that contain flammable or oxidizing gas with content greater than 250 cf are allowed for storage or use indoors.

- Exterior storage and use

- Cylinders must not be located under a window or within 5 m (20 ft) of smoking areas, open flames, or other ignition sources. Signs that prohibit smoking within 8 m (25 ft) of the storage or use area must be posted.

- Exterior locations must have a minimum of 25% of the perimeter open to the atmosphere and without walls.

- Cylinders of compressed gas in solution and liquefied gas must be stored and used in the upright position so that the pressure-relief valve is in direct contact with the vapor space of the cylinder, so that the gaseous product can be delivered.

- Interior storage and use

- Ventilation

- The EHS Research Support Team will determine when leak-point ventilation is required:

- Leak-point ventilation requirements generally do not apply to manufactured process equipment that has undergone adequate product safety evaluation and is specifically designed to handle small quantities of flammable gas.

- Negative-pressure local exhaust or positive-pressure dilution ventilation is required at all potential leak points in the gas system where the ventilation rate is less than six air changes per hour. Six air changes per hour is approximately 0.005 cubic meters per second (m3/s) per square meter – (one cubic foot per minute [cfm] per square foot) – of floor area.

- The EHS Research Support Team will determine when leak-point ventilation is required:

- Gas Detection

- Flammable-gas detection may be required where there is a possibility that a flammable-gas leak could be accidentally ignited in air.

- Flammable gas detection is required in the following situations:

- A hydrogen gas room (per CFC, Chapter 58)

- Vaults where compressed gases are generated, compressed, stored, or dispensed (per CFC, Chapter 53)

- Non-bulk hydrogen compressed gas systems above Maximum Allowable Quantity (MAQ) (per NFPA 55, Chapter 10, Gas Hydrogen Systems)

- Locations where ethylene oxide is dispensed (per NFPA 55, Chapter 14)

- Indoor locations where acetylene cylinders are charged (per NFPA 55, Chapter 15)

- Hydrogen equipment enclosures other than exhausted enclosures with gas volumes exceeding 1,000 scf (per NFPA 2, Chapter 7)

- High-Hazard Group Occupancies: The designation of a hazardous occupancy would be made during new construction or a major renovation.

- High-Hazard Group H-2 Occupancies: This occupancy includes buildings that pose a deflagration hazard or a hazard from accelerated burning, including flammable and combustible liquids or pyrophorics.

- High-Hazard Group H-5 Occupancies (Semiconductor fabrication): This occupancy includes buildings where semiconductor fabrication or comparable research is conducted involving hazardous production materials.

- When detection procedures for flammable gas are required, consult Appendix A to determine gas-detector system maintenance, audit, responsibility, selection, and installation requirements.

- Flammable Gas Mixtures

Table 13.4 lists the maximum concentration of hydrogen that is nonflammable when used as a component in inert gas mixtures commonly used at LBNL. For flammability ratings of other inert and flammable gas mixtures, contact the Gas Program SME or consult the Compressed Gas Association (CGA) P-23 Standard for Categorizing Gas Mixtures Containing Flammable and Non-flammable Components.

Table 13.4 Maximum Concentration (%) of a Flammable Component in a Non-flammable Binary Mixture

Flammable Component | Nonflammable | |||

|---|---|---|---|---|

| N2 | CO2 | He | Ar/Kr/Ne/Xe | |

| Hydrogen | 5.7 | 8.3 | 3.9 | 2.9 |

Operations that require a flammable and oxidizing gas mixture require review under the WPC process. If a fuel and oxidizer are to be mixed together, it is recommended to follow the precautions in CGA P-58, “Safe Preparation of Compressed Oxidant – Fuel Gas Mixtures in Cylinders.”

Work Process C. Pyrophoric Gases

- Pyrophoric gases are listed in the procurement restricted items list. Approval prior to purchase is required, and all pyrophoric gas use must be authorized by the EHS SME and the Fire Marshal’s Office in SES.

- In addition to the requirements in Work Process A, General Requirements – which includes general requirements for all compressed and hazardous gases – the following requirements and guidelines apply to the storage and use of pyrophoric gases.

- Additional requirements may apply to the storage and use of pyrophoric gas in quantities greater than 0.3 m3 (10 cf) for gas not in a gas cabinet and 0.6 m3 (20 cf) for gas in a gas cabinet. Further additional requirements apply for storage and use of pyrophoric gases that are also highly toxic gases.

- See Work Process D, Health-Hazard Gases, below for information on requirements for pyrophoric gases that are also health-hazard gases regarding gas purchase approval, cylinder delivery, cylinder return, and piping and component construction.

- Pyrophoric gases include diborane, phosphine, and silane. Diborane and phosphine are both pyrophoric and CFC Highly Toxic (NFPA Health Hazard Class 4) gases, and therefore require both pyrophoric and toxic (i.e., health hazard) gas safety controls. Silane is an NFPA Health Hazard Class 2 gas, but its primary hazard is pyrophoricity.

- Gas Storage and Use

- Locations, Barriers, and Cabinets

- Pyrophoric gases must be stored and used in gas cabinets or exhausted enclosures.

- Pyrophoric gas cylinders greater than 10 scf must be stored and used in a gas cabinet.

- For pyrophoric gases that are also toxic or highly toxic, a gas cabinet must be used, regardless of the size of the cylinder.

- Silane gas cylinders should be stored and used at exterior locations outside when possible. Whenever silane is being used outside of a gas cabinet, each silane cylinder must be separated from other hazardous gas cylinders by a non-combustible barrier with a material thickness of 6 millimeters (0.25 inches) and a width and height that extends at least 18 inches in front and above the cylinder. A Silane cylinder stored or used in an exterior location must be located in a shelter or bunker, provided with a chain-link fence to restrict entry and reduce the impact of an explosion at the location perimeter. The shelter must be separated from nearby buildings according to CGA G-13 requirements.

- Pyrophoric gases with an NFPA health-hazard classification of 3 or 4 must also have threaded, welded, or flanged connections throughout, except where connections are located within an exhausted enclosure. Swage-lock®-type connections are not permitted for any NFPA 704 health hazard 3 or 4 gases where the piping is located outside an exhausted enclosure.

- Only single-cylinder gas cabinets may be used for pyrophoric gases.

- Pyrophoric gas cylinders located in a gas cabinet must have mechanical ventilation at a minimum rate of 1 m/s (200 fpm) air velocity across the cylinder valve and gas fittings with the cabinet access port(s) closed.

- Pyrophoric gases must be stored and used in gas cabinets or exhausted enclosures.

- Gas Flow Controls

- A pyrophoric gas system at any pressure requires a Safety Note.

- A remote manual shutdown device for pyrophoric gas flow must be provided outside each gas cabinet or near each gas panel. A dispensing area must have an emergency shutdown mechanism for all gases that can be operated at a minimum distance of 5 m (15 ft) from the dispensing area. The emergency shutdown mechanism may be an accessible manual emergency shutoff valve or a remotely activated emergency shutoff valve. All emergency shutdown mechanisms must be marked with a sign.

- A pyrophoric gas flow, purge, and exhaust system must have redundant controls that prevent pyrophoric gas from igniting or exploding. These controls may include excess flow valves, restrictive flow orifices, mass flow controller sizing, process bypass line elimination or control, vacuum-pump inert-gas purging, dilution of process effluent with inert gas and ventilation, controlled combustion of process effluent, ventilation monitoring, and automatic gas shutdown.

- Piping and piping components must be compatible with the gas or gases in use (For details, see Work Process A, 6).

- For gas systems operated at a pressure greater than 15 psi, excess flow control or an emergency shutoff controlled by an approved leak detection system must be provided.

- Locations, Barriers, and Cabinets

Work Process D. Corrosive and Health-Hazard Gases (Toxic Gases)

- This section provides the requirements that apply to the storage use of corrosive and health-hazard gases (toxic gases), in addition to the general requirements that apply to all compressed and hazardous gases provided in Work Process A. See also Appendix D, Additional Information: Mixed Gases, Toxic Gases.

- Gas Health-Hazard Classification. Health-hazard gases, for the purposes of this chapter, include gases that at lower concentrations may cause significant acute or chronic toxic health effects including poisoning, and/or corrosion, irritation, and disease in human tissue.

- Acute Health Hazards. Table 13.5 presents standard CFC and NFPA acute-health-hazard gas classifications and shows each category’s relationship to lethal concentration values. These gas classifications must be used to determine which controls in this section are required for each gas use.

- Chronic Health Hazards. In contrast to acute-health-hazard gases, chronic-health-hazard gases can be pure or mixed chemicals under pressure in gas cylinders that have significant longer-term health hazards.

- Examples include CalOSHA Select Carcinogens as defined in 8 CCR 5191

- Gases that only present chronic health hazards: the EHS Research Support Team will assign a health-hazard classification and set of engineering controls based on the specific gas and its use.

| Table 13.5 Health-Hazard Gas Classifications | |||||

|---|---|---|---|---|---|

| Pure Gas LC50 (ppm) | Zero to 200 | Greater than 200 to 1000 | Greater than 1000 to 2000 | Greater than 2000 to 3000 | Greater than 3000 to 5000 |

| CFC Toxic Gas Classesa | Highly Toxicc | Toxic | N/A | ||

| NFPA Health Hazard Classesb | 4 | 3 | 2 | ||

| Footnotes: a CFC Highly Toxic and Toxic Gases: CFC Highly Toxic gases have a median lethal concentration (one-hour rate LC50) in air of 200 parts per million (ppm) by volume or less of gas. CFC Toxic gases have a LC50 greater than 200 ppm and less than or equal to 2000 ppm b NFPA Class 4, 3, and 2 Health Hazard Gases: NFPA Class 4 gases have a LC50 for acute inhalation toxicity that is less than or equal to 1000 ppm. NFPA Class 3 gases have a LC50 greater than 1000 ppm, but less than or equal to 3000 ppm. NFPA Class 2 gases have a LC50 greater than 3000 ppm, but less than or equal to 5000 ppm. c Excimer Gases: Mixtures of Excimer gases might not warrant classification as Highly Toxic. While this system is basically simple in application, any hazard evaluation that is required for precise categorization of this type of material must be performed by experienced, technically competent persons, including but not limited to the EHS Subject Matter Expert. Further guidance can be found in Appendix D, Additional Information for Mixed Gases and Toxic Gases. | |||||

c. Specific Gas Information. The EHS Research Support Team will assign health-hazard classifications and engineering controls to previously unclassified gases, dilute gases, and gas mixtures. For additional information see Appendix B for a list of specific health-hazard gases and their corresponding CFC and NFPA classifications, and Appendix D, Additional Information: Mixed Gases, Toxic Gases.

- Small Gas Concentrations and Quantities

- The required controls in this health-hazard gases section only apply to concentrations and quantities of gas that are sufficient to cause a gas-leak health hazard. A hazard exists at all potential leak points where a worst-case gas release will result in a small cloud of gas that is at or above the Ceiling Limit or Short-Term Exposure Limit (STEL) (or the Time-Weighted Average [TWA] if no Ceiling Limit or STEL is available).

- A leak health hazard exists if the concentration of gas inside the gas source (e.g., cylinder or gas line) is at or above the Ceiling Limit or STEL (or the TWA, if no Ceiling Limit or STEL is available). Exception: when a documented gas-release hazard evaluation shows that a leak hazard does not exist.

- The EHS Research Support Team will establish evaluation criteria as needed, review all leak-hazard evaluations, and approve evaluations that meet the requirements. For further guidance, see Appendix D, Additional Information for Mixed Gases, Toxic Gases.

- Gas Purchase Approval

- NFPA Health Hazard Classes 3 and 4 gases (and Class 2 gases with poor physiological warning properties), and their mixtures, require screening and approval prior to arrival onsite, regardless of how they are acquired (i.e. whether through LBNL Procurement or shipped by a collaborator). The decision maker/Requestor is responsible for following ES&H Manual Chapter 45 chemical acquisition requirements to ensure necessary approvals are obtained.

- Centralized Toxic Gas Receiving and Removal

- Scope. Toxic gases identified by the Tag field “Toxic Gases and Toxic Gas Mixtures” in CMS are required to follow centralized processes per this section. Low toxicity gas mixtures (e.g. calibration gases) identified in CMS by the tag “Reviewed Low Toxicity Gas Mixture” follow Work Process A. General Requirements.

- Receiving. After a toxic gas request is approved, the Gas Safety SME (or an EHS Research Support Team representative) will coordinate with the toxic gas owner (or representative) to be present at the time of arrival to oversee the toxic gas receiving process and specifically monitor for necessary approvals and controls, accurate cylinder attributes relative to the initial request, addition of RFID tags, toxic gas labels, and accurate information in CMS.

- The toxic gas owner/representative is responsible for notifying the Gas Safety SME or toxic-gas@lbl.gov of toxic gas deliveries not coordinated and received through the Gas Safety SME (or Research Support Team representative) as soon feasible for verification and completion of the receiving process.

- Removal. When a toxic gas is used up or no longer needed, the Gas Safety SME (or a Research Support Team representative) will coordinate removal, verification, CMS updates, and stakeholder notifications. The toxic gas owner/representative is responsible for:

- Requesting removal/disposal via the Toxic Gas Removal and Help form or by emailing toxic-gas@lbl.gov. NOTE: Do not use the GSS website gas return request form by Linde (Praxair) or Airgas for return/pickup of toxic gases.

- Ensuring that toxic gas cylinder RFID tags are not removed and the CMS status remains “active” while awaiting removal.

- Staging toxic gas cylinders in their approved, access controlled locations (e.g. ventilated gas cabinet, fume hood, other exhausted enclosure) until removed.

- Cylinders must not be transferred to an outdoor “pick up” rack.

- Any changes in storage location used for staging prior to removal must be approved storage locations meeting EHS and SES division requirements (i.e. authorized through WPC or by a request).

- CMS must be updated in a timely manner if cylinder storage locations are changed by the person who relocates the cylinder (or they must ensure that CMS is updated).

- Notifying toxic-gas@lbl.gov of any toxic gas cylinders removed (i.e. picked up by vendors) without the Gas SME (or representative) present to coordinate completion of the removal process (or verification).

- The chemical owner should obtain proof of removal such as photos of the vendor removal, a scan of the Bill of Lading, or receipt from vendor pick up.

- Resources:

- Gas Flow System. A gas flow system that handles NFPA Health Hazard Classes 2, 3, and 4 gases may require a Safety Note and must be designed and constructed in accordance with the requirements of Chapter 7 Pressure System Safety.

- Ventilation

- Area Ventilation. Area ventilation must be 0.005 m3/s per square meter (one cfm per square foot) of floor area or greater and must be maintained at negative pressure relative to adjacent corridors and non-laboratory or non-gas-use areas.

- General Local Exhaust Requirements. NFPA 704 Health-Hazard Classes 3 and 4 gases, NFPA Health–Hazard Class 2 gases with poor physiological warning properties, CFC highly toxic gases and CFC toxic gases:

- Gas cylinders must be kept in a laboratory hood or gas cabinet.

- All piping connections must be welded, threaded, or flanged, unless connections are located within an exhausted enclosure.

- Process Equipment Enclosures. When process equipment enclosures are exhausted, ventilation face velocities at all enclosure holes, cracks, and access ports that may need to be opened in a gas emergency must be 0.5 m/s (100 fpm) or greater. Where emergency access is needed, small (not large) access doors must be used to reduce exhaust requirements.

- Purge Vents and Exhaust Lines

- All lines or ducts carrying purged or exhausted emissions of health-hazard gases must be connected to an approved exhaust system.

- Corrosive gas venting: Significant emissions from corrosive gas venting may require the use of an emissions control device (e.g., scrubber) to prevent duct corrosion before the purged gas can be vented into the exhaust duct system.

- Ventilation Monitoring and Interlocks

- CFC Highly Toxic and Toxic Gases. A ventilation monitor with audible and visual alarms is required on the lab hood or gas cabinet where the gas cylinder is kept.

- Ventilation monitoring interlocked with automatic gas shutdown may be used in addition to or in place of audible and visual ventilation monitor alarms. In addition, automatic gas shutdown is required based on the gas’s physiological warning properties, as shown in Table 13.6. Ventilation monitoring interlocked with automatic gas shutdown is also recommended for CFC Highly Toxic gases.

- Accident Release Evaluation and Control

- Gas release controls must be implemented to reduce Highly Toxic and Toxic gas exhaust stack discharge concentrations to 50 % of the IDLH levels (or less) at the point of discharge into the atmosphere.

- Highly toxic and toxic gases procured on Berkeley Lab’s eBuy system from Praxair (Linde) are delivered with a 0.010 inch RFO on cylinders larger than a lecture bottle (lecture bottles will not accept RFOs).

- If the resulting toxic or highly toxic gas concentration at the stack is less than or equal to 50 % of the IDLH, the combination of ventilation and an RFO satisfies the control requirements. However, depending on the gas system and/or location, additional engineering controls may be required. For example, in semiconductor fabrications, additional controls will be required, including but not limited to gas cabinets with gas panels, excess flow, automatic shutoff valves, toxic gas monitoring systems, etc. Contact the Gas Safety program SME for assistance.

- If an experimental system requires greater gas flows than a cylinder with an 0.010 inch RFO provides, the RFO may be replaced with a larger RFO, but only after a hazard analysis has been performed and the EHS SME agrees that the changes will not result in a gas exposure at the exhaust stack that is greater than 50% of the IDLH.

- For lecture bottles or other cylinder that cannot accept an RFO, calculate the stack discharge.

- If stack discharge is less than or equal to 50% of the IDLH, ventilation alone is generally enough to satisfy control requirements (additional controls described above may still apply for specific types of systems and/or locations).

- If stack discharge is greater than 50 % IDLH, other engineering controls are necessary (e.g. provide an engineered gas flow shutoff system) to reduce the discharge concentration to less than 50% IDLH. More information is provided in Appendix D or contact the Gas Safety program SME for additional assistance.

- If use of an RFO and/or ventilation does not satisfy the control requirements and the toxic or highly toxic gas concentration at the stack exceeds 50% of the IDLH, additional administrative controls would also be required. For example: while toxic gases are flowing and exhausted via the local exhaust ventilation system, no personnel will be permitted to work on the roof, and access will be controlled using a lock and key. This would be in addition to other added engineering controls (e.g. engineered gas flow shutoff system).

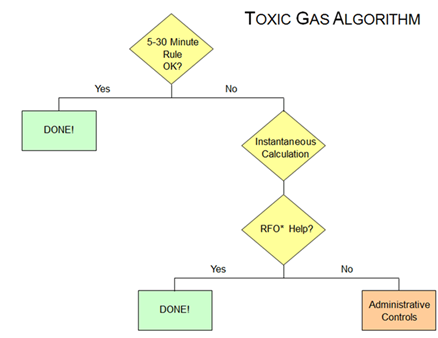

- When the worst-case catastrophic release of a hazard gas is analyzed and controls evaluated, the catastrophic-gas release rate is calculated using the 5-minute and 30-minute release criteria, depending on whether the gas is non-liquefied (5 minutes) or liquefied (30 minutes).

- The following decision tree diagrams the graded approach in calculating the worst-case release for Toxic and Highly Toxic gases.

- Gas Detection

- The need for health-hazard gas detection must be based on the following criteria: gas concentration, quantity, and physiological warning properties.

- Poor physiological warning conditions exist when the concentration and warning properties of the gas are at or above the Ceiling Limit or STEL (or the TWA if no Ceiling Limit or STEL is available) as determined by the EHS Research Support Team. Physiological Warning Property Ratings for health hazard gases are provided in Table 13.6 below.

- In general, gas detection for the area of use or storage is required when the quantity of health-hazard gases exceeds the maximum allowable quantity (MAQ). Health-hazard gas detection is always required under the following conditions:

- Use of highly toxic gases when exceeding a total of 40 cf (the MAQ) in an LBNL fire control area equipped with fire sprinklers.

- Use of toxic gases with poor physiological warning properties when exceeding a total of 1620 cf (the MAQ) in an LBNL fire control area equipped with fire sprinklers.

- Gas detection and/or other controls such as leak detection with automatic shutdown or specific ventilation requirements may be required under other conditions. Contact the Gas Safety Program SME or the Fire Marshal’s Office at extension 4861 to review your specific application.

- When gas-detection methods are required, use Appendix A to determine gas-detection system maintenance, audit, responsibility, selection, and installation requirements.

| Table 13.6 Physiological Warning Property Ratings for Select Health-Hazard (Toxic) Gases Source: AIHA Odor Thresholds for Chemicals with Established Occupational Health Standards | ||

|---|---|---|

| Dimethylamine (U) | nitrosyl chloride (A) | |

| 1,3-butadiene (G*) | ethylene oxide (p*) | oxygen difluoride (P) |

| ammonia (G*) | fluorine (M*) | perchloryl fluoride (U) |

| arsenic pentafluoride (U*) | germane (U*) | perfluoroisobutylene (U) |

| arsine (P*) | germanium tetrafluoride (U) | phosgene (P*) |

| boron trichloride (A*) | hexafluoroacetone (P*) | phosphine (P*) |

| boron trifluoride (P*) | hydrogen bromide (A*) | phosphorous pentafluoride (A*) |

| bromine chloride (U) | hydrogen cyanide (P*) | phosphorous trichloride (P*) |

| bromine pentafluoride (P) | hydrogen fluoride (A*) | phosphorous trifluoride (P*) |

| bromine trifluoride (P) | hydrogen selenide (P*) | selenium hexafluoride (P) |

| carbon monoxide (P*) | hydrogen sulfide (M*) | silane (M*) |

| carbonyl fluoride (U*) | hydrogen telluride (U) | silicon tetrachloride (A*) |

| carbonyl sulfide (U) | iodine pentafluoride (U) | silicon tetrafluoride (A*) |

| chlorine (A*) | methylamine (G*) | stibine (P*) |

| chlorine pentafluoride (U) | methyl bromide (P*) | sulfur dioxide (G*) |

| sulfur tetrafluoride (P*) | ||

| chlorine trifluoride (M*) | methyl chloride (M) | sulfuryl fluoride (P) |

| cyanogen (P) | methyl silane (U) | tellurium hexafluoride (P) |

| cyanogen chloride (P) | nickel carbonyl (P) | trimethylamine (G*) |

| diazomethane (U) | nitric oxide (G*) | trifluoroacetyl chloride (U) |

| diborane (P*) | nitrogen dioxide (A*) | tungsten hexafluoride (A*) |

| dichlorosilane (A*) | nitrogen trifluoride (p*) | vinyl chloride (P*) |

| (A) Adequate: Warning properties are fairly well understood and occur at or below the lowest PEL or TLV. Data uncertainties may exist. (E1) Exception 1: A ventilation monitor must be installed, but may not need to be interlocked with gas shutdown if procedures for the operation require: (1) an operator to be present at all times while the gas cylinder valve is open, and (2) the gas cylinder valve to be closed if the ventilation alarm is activated. Exceptions must be approved by the EHSS Research Support Team. (E2) Exception 2: If no gas-detection system is available, control measures that provide an equal level of safety must be used. (G) Good: Warning properties are well understood and occur at or below the lowest PEL or TLV. (M) Marginal: Warning properties are marginally adequate and are most likely to occur at or below the STEL (or TWA, if no STEL or Ceiling Limit is available). Data uncertainties may exist. (P) Poor: Warning properties occur at or above the STEL or Ceiling Limit (or TWA, if no STEL or Ceiling Limit is available). Many data uncertainties may exist. Gas may have high-hazard toxicity properties. (U) Undetermined: Information on warning properties is lacking. EHSS will evaluate on a case-by-case basis. (*) Available gas-detection system(s) have been identified. (—) No general requirement. |

|---|

13.8 Source Requirements

- California Code of Regulations, Title 24, Part 9, California Fire Code:

- Chapter 35, Welding and Other Hot Work

- Chapter 27, Semiconductor Fabrication Facilities

- Chapter 53, Compressed Gases

- Chapter 50, Hazardous Materials- General Provisions

- Chapter 61, Liquefied Petroleum Gases

- California Code of Regulations, Title 8, General Industry Safety Orders (GISO) and Construction Safety Orders (CSO)

- GISO 3304, Miscellaneous Use of Compressed Cylinder Gas

- GISO 4650, Storage, Handling, and Use of Cylinders

- GISO 5465-5489, Hydrogen Systems

- GISO 5500-5509, Oxygen Systems

- CSO 1740-1743, Oxygen, Acetylene and Fuel Gas

- GSIO 5155, Airborne Contaminants

- GISO 5194, Hazard Communication

- GISO 5191, Occupational Exposure to Hazardous Chemicals in Laboratories.

- 49 CFR, Transportation, Parts 100–199

- DOE Order 430.1C, Real Property Asset Management

- DOE Order 5480.4, Environmental Protection, Safety, and Health Protection Standards, sections specified in Work Smart Standards set (current version)

- DOE Order 422.1, Admin Chg 2, Conduct of Operations

13.9 Reference Documents

| Document Number | ESH Manual Reference | Title | Type |

|---|---|---|---|

| 07.01.002.000 | Chapter 1 | General Policy and Responsibilities | Program |

| 07.07.013.000 | Chapter 4 | Exposure Assessment | Program |

| 07.07.026.000 | Chapter 7 | Pressure Safety | Program |

| 07.11.001.000 | Chapter 12 | Fire Prevention and Protection | Program |

| 07.04.001.000 | Chapter 24 | EH&S Training | Program |

| 07.07.009.001 | Chapter 29 | Safe Handling of Cryogenic Liquids | Program |

| 07.07.005.000 | Chapter 45 | Chemical Hygiene and Safety Plan | Program |

Non-LBNL References

- American Conference of Governmental Industrial Hygienists

- Industrial Ventilation,a Manual of Recommended Practice, current version

- Threshold Limit Values for Chemical Substances and Physical Agents (current version)

- American Industrial Hygiene Association, Odor Thresholds for Chemicals with Established Occupational Health Standards, 1997)

- American National Standards Institute (ANSI)/AIHA Z9.5-1992, American National Standard for Laboratory Ventilation

- American Society of Mechanical Engineers (ASME)/ANSI A13.1 Scheme for the Identification of Piping Systems, 2013

- Compressed Gas Association

- Pamphlet P-1, Safe Handling of Compressed Gases in Containers

- Pamphlet P-12, Safe Handling of Cryogenic Liquids

- P-20-2009, Standard for the Classification of Toxic Gas Mixtures

- P-23 2008, Standard for Categorizing Gas Mixtures Containing Flammable and Non-flammable Components

- P-58 2015 Safe Preparation of Compressed Oxidant – Fuel Gas Mixtures in Cylinders

- National Fire Protection Association

- NFPA 45, Fire Protection for Laboratories Using Chemicals

- NFPA 50A, Gaseous Hydrogen Systems at Consumer Sites

- NFPA 51, Design and Installation of Oxygen-Fuel Gas Systems for Welding, Cutting and Allied Processes

- NFPA 51B, Standard for Fire Prevention During Welding, Cutting, and Other Hot Work

- NFPA 55, Compressed Gas and Cryogen Fluids Code

- NFPA 72, Installation, Maintenance, and Use of Protective Signaling Systems

- NFPA 704, Identification of the Fire Hazards of Materials

- National Institute of Occupational Safety and Health, Pocket Guide to Chemical Hazards, DHHS (NIOSH), Pub. No. 90-117

- University of California Lab Design Guide (2nd Edition)

13.10 Appendices

Appendix A. Gas-Detection System Requirements

Appendix B. Specific Health-Hazard (Toxic) Gas Classifications

Appendix C. Gas System Component Information

Appendix D. Additional Information: Mixed Gases and Toxic Gases

Appendix A. Gas-Detection System Requirements

This appendix contains requirements for maintenance, selection, and installation of gas-detection systems. Explanations for when gas detection is required are presented in Work Process A, General Requirements; Work Process B, Flammable Gases; and Work Process D, Corrosive and Health-Hazard (Toxic) Gases.

- Detection System Maintenance

- General Maintenance Requirements

- The principal investigator or gas-use supervisor is primarily responsible for the management of gas-detection system maintenance related to their project or operation.

- Maintenance must at a minimum follow manufacturer’s recommendations, including frequency of maintenance. If applicable, testing of the detection system’s ability to detect and transmit a signal to the Fire Department must follow NFPA guidelines, or must occur on at least a quarterly basis. The Facilities Department will provide technical guidance, if requested.

- Maintenance Personnel

- The principal investigator may assign maintenance tasks to qualified subordinates, the Facilities Department, or contractors.

- Personnel conducting detector maintenance must be adequately trained, have detector manufacturer recommended training or equivalent, and be certified as “qualified” maintenance personnel.

- Maintenance Documentation

- A formal system of documentation will be maintained for each gas-detection system, and will include:

- Manufacturer’s operation and service manuals

- Preventive maintenance procedures, post-maintenance testing, schedules, and records of results

- Procedures and records for verifying proper connection of detector alarms and interlocks

- Records of all repairs, calibrations, non-routine maintenance, and system failures

- Names and qualifications of maintenance personnel

- Calibration source documentation

- A one-year summary (e.g., log) of function checks and maintenance actions performed must be visibly maintained on or near the detector system. Minimum summary information must include the date, person’s name, and action taken.

- A formal system of documentation will be maintained for each gas-detection system, and will include:

- General Maintenance Requirements

- Detection System Selection

- Listing. To ensure that a detection system meets requirements, it must be:

- Listed by Underwriters Laboratory or Factory Mutual, or

- Listed by the Canadian Safety Association and the California State Fire Marshal’s office, or equivalent.

- Note: if only unlisted equipment is available, the SES Fire Marshal may approve unlisted equipment upon evaluation.

- Performance. The gas detector sensor must be able to detect gas below the lowest Permissible Exposure Limit (PEL) or Threshold Limit Value (TLV) for health hazard gases and/or at or below 10–15% of the Lower Explosive Limit (LEL) level for flammable gases.

- Hardware. System hardware must include:

- Separate relays for “warning” (low-concentration gas detection), “alarm” (high-concentration gas detection), and “trouble” (malfunction) conditions, and normally open and normally closed dry-contact-relay output capability for specified but adjustable levels of gas detection

- Capability system that is installed as fixed-in-place, with hard-wired and plumbed connections

- Control protection from direct unauthorized personnel access

- Listing. To ensure that a detection system meets requirements, it must be:

- Detection System Installations

- Design. Detection system installations will be designed and documented (i.e., plans and as-built drawings) by the Facilities Department. A Facilities Department licensed professional engineer and SES Fire Protection SME must approve all designs prior to contract award or installation. In addition, an EHS SME must approve all toxic and oxygen-deficiency-detection system designs.

- Alarm Signal Transmission Options. Detection system alarms must be used under one of the following scenarios:

- Set up for a local alarm only. This is the minimum allowed and provides for evacuation of the space(s) that may be affected during a gas release.

- Set up for a local alarm and for detection via a Facilities maintained monitoring system. This will trigger a response by Facilities personnel as well as providing the local alarm.

- Setup for a local alarm, a Facilities maintained monitoring system, and connection to the fire alarm system. This will trigger a Fire Department response as well as a Facilities response and a local alarm.

- Setup for a local alarm and connection to the fire alarm system. This will trigger a local alarm and a Fire Department response. This could be used in older buildings where a Facilities monitoring system is not capable of supporting gas detection.

- Connection to a fire alarm system must be reviewed by a SES Fire Protection SME, and generally requires a system that is listed and approved for connection. Specific alarm trigger points are discussed below.