Contents

Approved by Jonathan Cabrera

Revised 9/25

17.1 Policy

17.2 Scope

17.3 Applicability

17.4 Exceptions

17.5 Roles and Responsibilities

17.6 Definitions

17.7 Work Processes – Elements of the Ergonomics Program

- Work Process A. Ergo Control Measures

- Work Process B. Office, Lab, and Manual Material Handling Ergo

- Work Process C. Ergo Evaluations

- Work Process D. Training

- Work Process E. Support for Off-Site/Remote Computer Users

- Work Process F. Resources

17.8 Source Requirements

17.9 Reference Documents

Note:

🚩🚩 Denotes a new section

🚩 Denotes the beginning of changed text within a section

🛑 Denotes the end of changed text within a section

_____________________

17.1 Policy

The Ergonomics Program at Lawrence Berkeley National Laboratory (Berkeley Lab) assists all Laboratory divisions in identifying, preventing, and controlling ergonomics risk factors. The Ergonomics Program strives to be a value-added program that is integrated into the safety culture at Berkeley Lab.

The goal of the Ergonomics Program is to optimize work practices, software, furniture, tools, and equipment used at Berkeley Lab to increase employee effectiveness and to minimize employee exposure to risk factors for work-related musculoskeletal disorders (WRMSDs).

17.2 Scope

The Ergonomics Program facilitates work performed at Berkeley Lab by taking a systematic view of people, their work tasks, work space, software, and equipment to help create an environment where people can work safely and efficiently.

The Ergonomics Program operates at three levels to achieve these goals:

- Prevention: Work with end-users, vendors, and procurement representatives to ensure that tools, equipment, work processes, and computer software are user-friendly and do not present unnecessary risks such as repetition, high force, awkward postures, or wasted time and motion. At this level, the emphasis is on minimizing risks before investing in new tools or implementing new processes.

- Customer Care: Work with individual employees and supervisors to control/minimize employee discomfort, implement physical and work-process changes to mitigate risk factors for musculoskeletal problems, and accommodate diverse body sizes and work styles to allow them to work as comfortably and effectively as possible.

- Alignment: Collaborate with science and operations divisions/departments and their Division Safety Coordinators to ensure Ergonomics Program elements are in place to mitigate ergonomics issues (e.g., injury-prone tasks, complex material-handling jobs, unique equipment integration, new laboratories, that might affect the health and safety of their employees) at a local level.

The Ergonomics Program consists of:

- A team of ergonomists and support personnel within the Environment, Health, and Safety (EHS) Division

- Division Ergo Advocates and Division Safety Coordinators in each division who are responsible for the early identification of ergonomic issues, performing preventive ergonomic (ergo) evaluations for onsite office and telework locations, and providing ergo recommendations for employees

- Ergonomic tools and resources that can be used for addressing ergonomic issues, including:

- The Ergo Database for requesting and managing ergo evaluations

- Ergo Training (Online)

- The Onsite Ergo Catalog

- The Telework Catalog

- The Ergonomics website offers comprehensive information about the Ergonomics Program, including available resources; guidance; support tools for computer use, laboratory work, and material handling, for all modes of work (i.e., onsite, hybrid, full time telework or full time remote worker)

- The Ergo Display Room where employees can test furniture or equipment and access loaner products to ensure they are effective at mitigating risks and providing comfort

- An ergo “quick fix” product inventory that enables the Ergo Team to rapidly deploy products such as seating, keyboards, mice, forearm supports, etc., particularly when employees are experiencing discomfort

The Ergonomics Program performs the following functions:

- Tracks and responds to ergonomics-related risk factors and discomfort requests

- Collaborates with individuals, groups, and divisions at Berkeley Lab on ergonomic evaluations and improvement efforts

- Coordinates as needed with managers, supervisors, Division Safety Coordinators, and Health Services to help employees, affiliates, and students to mitigate risks and minimize discomfort they might experience at work

- Provides in-person and/or virtual ergonomic evaluations and training where ergonomic risk factors or discomfort are of concern

- Manages the online Ergo Training and self-assessment system and works with Laboratory-wide users to reduce employees’ ergo risk levels.

- Reviews and evaluates division ergonomics programs, and assists them with their ergonomics efforts, e.g., ergo campaigns and training, safety self-assessments, quick-fix inventories, etc.

17.3 Applicability

This program applies to all Berkeley Lab employees, affiliates, and Laboratory-supervised subcontractors. Any represented employee can refer to the Human Resources webpage for more information.

17.4 Exceptions

None

17.5 Roles and Responsibilities

|

Role |

Responsibilities |

|

Division directors |

|

|

Managers, supervisors, and work leads |

|

|

Employees |

|

|

Division Safety Coordinators (DSCs) |

|

|

Division Ergo Advocates |

|

|

Ergonomist |

|

|

Health Services |

|

|

Procurement & Property Management Department, Office of the Chief Financial Officer |

Prepares purchase requisitions to acquire furniture, equipment, and accessories. The buyers in this department monitor the types of products being ordered to ensure they meet ergonomic criteria specified by the EHS Division. |

|

Space Planning |

Integrates ergonomic considerations into workspace planning, workstation design, building modifications, and move coordination with the goal of accommodating employees of various sizes and job functions while facilitating changes in technology and work processes over time. |

17.6 Definitions

Term | Definition |

Discomfort evaluation | Performed by the EHS Ergo Team. Requested to address the needs of employees with discomfort. |

Ergonomics

| The study of human interaction with tools, equipment, software, work processes, and the environment in which people function. The goal is to fit the job to the person. Ergonomics recognizes the capabilities, differences, and limitations of individuals, and adjusts the tools, work process, or work environment accordingly. |

Ergonomic evaluation | An ergonomic evaluation (ergo eval) is performed by the EHS Ergo Team and Ergo Advocates to observe a worker’s workstation, workplace, and/or behaviors (e.g., body mechanics) to identify risk factors and enhancements. |

| Hybrid work | A hybrid work mode is an arrangement where an employee is required to work on-site for a portion of their time but can telework effectively from an alternate non-Berkeley Lab location for the balance of their work time. A hybrid work mode location is expected to be within local commuting distance (i.e., 150 miles from Berkeley Lab). |

| Full-time telework | A full-time telework mode is an arrangement for an employee to work from a site other than Berkeley Lab, provided the site is within 150 miles from Berkeley Lab. Employees in the full-time telework mode are expected to work on-site on an occasional basis as required by business or operational need. |

| Full-time remote work | A full-time remote work mode is an arrangement to work from a site further than 150 miles from Berkeley Lab, provided the site is within the domestic United States. This type of work mode occurs when the employee works exclusively off-site as part of the terms and conditions of employment and does not maintain an office on a Berkeley Lab site. This work mode requires a formal written and approved Remote Work Agreement. |

Manual material handling | Materials being moved directly by people: Includes lifting, carrying, pushing, pulling, reaching, bending, and crouching to move and handle objects manually. |

Move evaluation | Performed by the EHS Ergo Team and Ergo Advocates. Can be requested when an office move occurs and an employee wants to ensure the new set up is optimal and safe. |

Preventive evaluation | Performed by the EHS Ergo Team, but more commonly performed by Ergo Advocates. Can be requested to proactively address ergonomic issues for new or existing employees. |

Risk factors | Conditions that contribute to the risk of developing a disorder. In the case of work-related musculoskeletal disorders, these include awkward postures, highly repetitive activities, the application of high forces, static positions (maintained over long periods of time), exposure to hand-arm or whole-body vibration, and exposure of hands or feet to temperatures cold enough to cause discomfort. |

| Telework evaluation | Performed by the EHS Ergo Team and Ergo Advocates. These evaluations are conducted virtually and can be requested for individuals that are authorized to telework or work from home. |

|

Work-related musculoskeletal disorder (WRMSD) | The term used for health disorders arising from biomechanical stresses on the body, including those of a cumulative nature. WRMSDs are disorders of the muscles, tendons, and/or nerves that develop from or are aggravated by repeated or sustained exertions on the body. WRMSDs are also referred to as cumulative trauma disorders, repetitive motion injuries, repetitive strain injuries, repetitive trauma disorders, and overuse injuries. |

17.7 Work Processes – Elements of the Ergonomics Program

- Work Process A. Ergo Control Measures

- Work Process B. Office, Lab, and Manual Material Handling Ergo

- Work Process C. Ergo Evaluations

- Work Process D. Training

- Work Process E. Support for Off-Site/Remote Computer Users

- Work Process F. Resources

Work Process A. Ergo Control Measures

- Understanding Risk Factors: Identifying and reducing ergonomic risk factors is a key to preventing WRMSDs. Ergo risk factors include repetitive, forceful, or prolonged exertion of the hands; frequent or heavy lifting; pushing, pulling, or carrying objects; prolonged awkward postures; cold temperatures; and vibrations contribute to the risk of WRMSDs. The level of risk depends on how long a worker is exposed to these conditions, how often a worker is exposed to them, and the level of exposure.

- Eliminating/ Reducing Risk Factors: Physical changes to the tools or workplace should be addressed as the first line of defense to eliminate or reduce ergonomic risk factors. It is important to implement solutions that can eliminate the risk factors when feasible.

- Good Body Posture: Reducing the length of time spent in awkward postures is important for minimizing the risk of developing a WRMSD. Equipment, tools, furniture, and the visual demands of a job have a direct effect on posture.

Awkward postures (left) improved by ergonomics interventions (right)

- Other Control Measures

- Broadening Range of Tasks: Have employees perform more parts of a job rather than one specific task repeatedly, as long as this involves the use of different muscle groups.

- Job Rotation: Cross-train employees to perform other jobs. Rotate employees in jobs that use different muscle groups, if possible.

- Work Breaks: Have employees take frequent short breaks from static postures or repetitive tasks throughout the day.

- Early Reporting and Intervention

- The Berkeley Lab Ergo Team is highly effective in preventing discomfort from progressing into an injury when discomfort is reported early, as soon as an employee is feeling discomfort. It is important for employees to report discomfort to their supervisor, to ask their supervisor for an ergonomics evaluation, and/or to contact the Ergo Team for an ergonomics evaluation. Discomfort does not equal injury. Everyone has discomfort at some point. Early reporting is key to preventing discomfort from turning into an injury.

- When employees report DISCOMFORT, supervisors are encouraged to:

- Provide positive feedback to the employee for reporting their discomfort

- Immediately notify their Division Safety Coordinator

- Submit a request for an ergonomist to perform an ergo evaluation through the Ergo Database

- Discuss initial findings and observations with the ergonomist

- Review the ergo evaluation summary, and implement actions assigned to you

- Check in with the employee often to make sure the recommendations are working and that the employee’s discomfort is subsiding

- Discuss with the employee the need to seek medical treatment from Health Services if discomfort is not subsiding after recommendations are implemented

Work Process B. Office, Lab, and Manual Material Handling Ergo

- Office Ergo: A computer workstation should be designed to accommodate each user. Furniture adjustability is the key, as it allows each employee to fit his or her individual needs. The best choice for working patterns and postures will differ from one person to another, based on the type of work performed.

- Lab Ergo: Laboratory tasks can include awkward postures, precision work with hands, reaching, and bending forward. The Berkeley Lab Ergonomics Program aims to address ergonomics risks in the laboratories. Please contact ergo@lbl.gov for assistance in examining your laboratory area/tasks.

- Manual Material Handling Ergo: When ergonomics is applied at an industrial work area (e.g., workshops, hand-tool use, material handling, and process areas), it is known as industrial ergonomics. The same WRMSD risk factors are relevant and good work practices and body posture should be employed to minimize muscle tension and strain.

- Hand Tools: A tool that is poorly designed, maintained, or inappropriately used can cause WRMSDs. Hand tools should fit the employee’s hand. Employees with small hands or who are left-handed may need tools designed specifically for these situations. A tool that works well in one situation may expose the user to awkward postures, harmful pressures on the hand, or excessive vibration in another situation.

- Manual Material Handling

- Manual material handling involves lifting, lowering, and carrying objects. If ergonomics principles are ignored, stresses on the muscles, joints, and disks in the back can eventually lead to or aggravate a WRMSD. For objects that are too heavy or bulky for safe manual handling by employees, mechanical lifting devices must be used for lifting and moving (See Chapter 27, Cranes, Hoists, and Rigging Safety and Chapter 28, Forklifts and Other Powered Industrial Trucks).

- Mechanical lifting devices (rather than manual effort) are the best first option to lift and move objects whenever practical and feasible. This is especially important for tasks involving heavy, awkward, repetitive, or transporting items long distances.

- The Ergo Team has tools and resources to provide guidance and assistance in determining the risks and safe limits for lifting, pushing, pulling, and carrying.

- Guidance for safe lifting: the maximum safe limit for one person is 50 pounds. The maximum safe limit for two-person lifts is 75 pounds. There are conditions and circumstances where the safe limits are less. It is recommended that tasks involving heavy lifting should be reviewed and planned. Consultation from the EHS Ergonomics Team is available.

- Lifting limits should also take into account the weight of the load, location of the load, the frequency and duration of lifting, and whether lifting involves twisting.

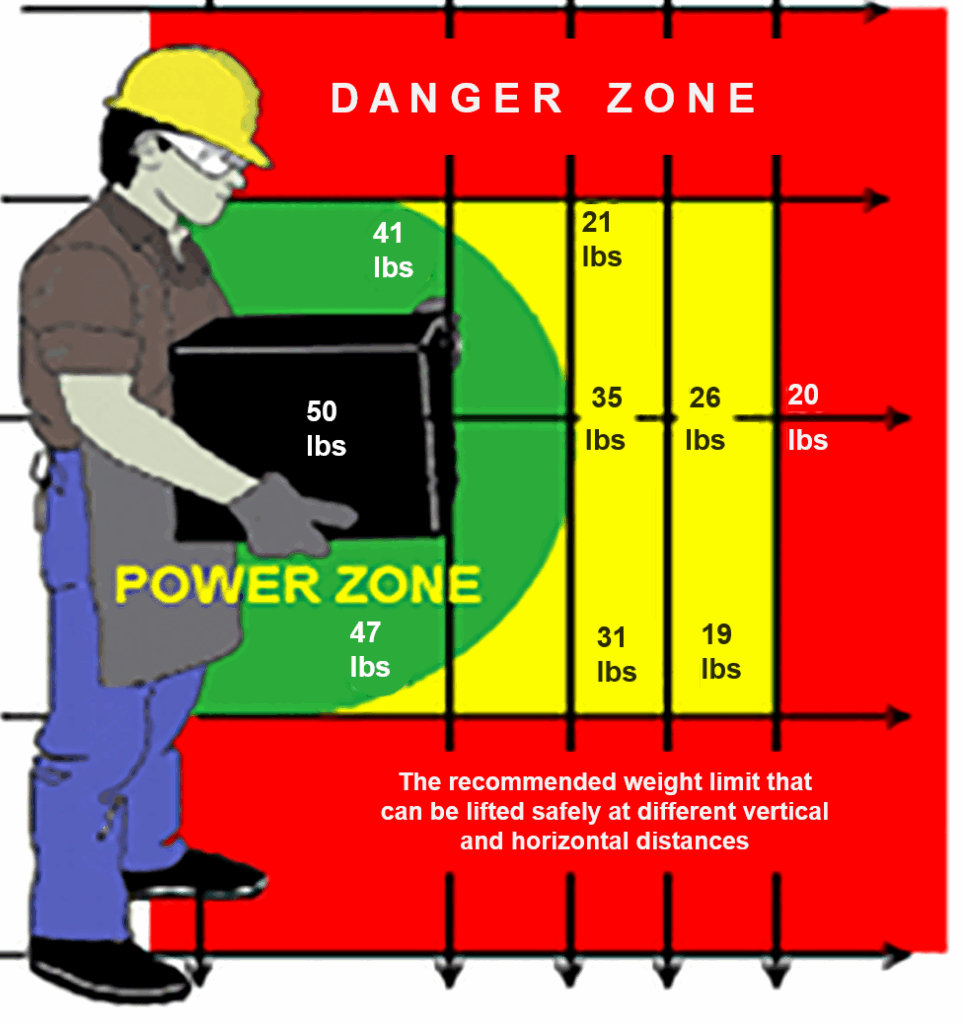

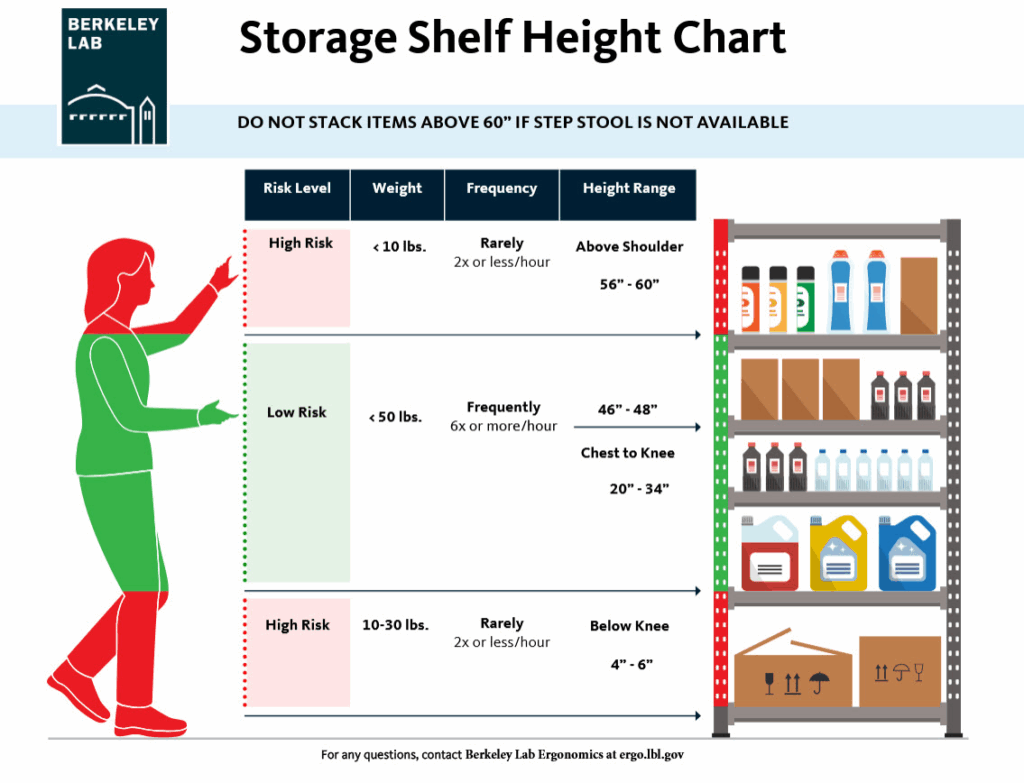

- Berkeley Lab–Recommended Lifting Limits (in Pounds) as Shown in Diagrams 1 and 2.

- Recommended weight limit that can be lifted safely at different vertical and horizontal distances.

Diagram 1. Power Zone

Diagram 2. Recommended Storage Shelf Heights

Tables adapted from the American Conference of Governmental Industrial Hygienists (ACGIH), Threshold Limit Values for Physical Agents, Ergonomics, 2016.

Work Process C. Ergo Evaluations

- Purpose: Ergo evaluations can be performed for individuals, groups, and work areas for office, lab, and material-handling tasks. Ergo evaluations identify ergo risk factors, and propose solutions for preventing and reducing risk.

- Requesting an Ergo Evaluation: Preventive, move, and discomfort ergo evaluations can be requested by accessing the Ergo Database.

- Using the Ergo Database: The Ergo Database is the primary system for managing ergo evaluations. It is used for communication, monitoring, tracking, and referencing past and current ergo evaluation information. The Ergo Database is used as a means of entering observations and recommendations, and tracking the actions stemming from the evaluation.

Work Process D. Training

Ergo training resources include:

- EHS0059 Ergo Self-Assessment for Computer Users and EHS0058 Ergo Self-Assessment Refresher

- EHS0061 Ergo Advocate Training

- EHS0062 WorkSmart Ergonomics

Work Process E. Support for Telework/Remote Computer Users

- The Ergonomics Program offers support services for Berkeley Lab employees who use computers for telework/remote work locations.

- Employees approved for telework/remote work should request assistance to optimally set up their home office by:

- Requesting a preventative home office evaluation in the ergo database. The evaluation request will be assigned to an ergo advocate who will request for photos of the home office set up and arrange for a virtual evaluation to be completed.

- Requesting a discomfort home office evaluation to obtain assistance with implementing any recommendations deemed necessary to control risk factors for work-related musculoskeletal disorders (WRMSDs).

- Obtaining equipment such as chairs, keyboard, mice, etc. through the telework catalog. Purchase of telework items just requires supervisor approval.

- For additional information on telework and remote work, visit Telework.lbl.gov.

Work Process F. Resources

Several ergonomic-specific resources are available to support Berkeley Lab employees:

- The Ergo Display Room is located in Building 26, Room 004. With the assistance of an Ergo Team member, employees can try out various ergonomic furniture and accessories. Some items are available to borrow and use at the employee’s workplace on a trial basis. The purchase of ergonomic furniture and accessories is the responsibility of each employee to obtain supervisor approval and coordinate purchase of the equipment. The cost is the responsibility of the employee’s division. Ergo Display Room visits are by appointment only and can be requested by contacting the EHS Ergonomics Team at ergo@lbl.gov.

- The Ergo Catalogs Web page lists catalogs for onsite office and lab products as well as services, including computer glasses, ergo-related facilities services, posture/habits recommendations, and the Ergo Display Room.

- Ergo.lbl.gov is the Laboratory’s one-stop shop for all ergo-related information, including Quick Links, Ergo Program Resources, Work Area Resources, Ergo Online Training, The Way We Work resources, etc.

- The 1 Minute 4 Safety slides are designed to assist Berkeley Lab supervisors and managers in conducting discussions on Environment, Safety & Health (ES&H) topics with their staff. The slides can be either downloaded or printed.

- RSIGuard is a site-licensed break-reminder software available for either Macs or PCs. RSIGuard has customizable break reminders, microbreaks (forget-me-nots), key controls, and auto-click features.

- Contacts

- Health Services: Provides medical consultation and treatment as needed for injured employees

- Facilities: Provides assistance with fulfilling work-order requests such as lighting and furniture changes or moves

- Procurement & Property Management Department: Provides assistance with ordering ergo-related furniture and accessories via ePro or eBuy

- EHS Ergo Team: Berkeley Lab’s one-stop shop for all ergo-related services, information, and resources

17.8 Source Requirements

- 10 CFR 851, Worker Safety and Health Program

- 10 CFR 851.10(a)(1), General Requirements

- 10 CFR 851.11, Development and Approval of Worker Safety and Health Program

- American Conference of Governmental Industrial Hygienists (ACGIH), “Threshold Limit Values for Physical Agents,” Ergonomics, 2016

- California Code of Regulations (Cal/OSHA), Subchapter 7, General Industry Safety Orders, Group 15, Article 106, Ergonomics, §5110, Repetitive Motion Injuries

17.9 Reference Documents

- Chapter 3 Health Services

- Chapter 24 EHS Training Program

- Chapter 27 Cranes, Hoists, and Rigging Safety

- Chapter 28 Forklifts and Other Powered Industrial Trucks

- Requirements and Policies Manual – Flexible Work

_____________________