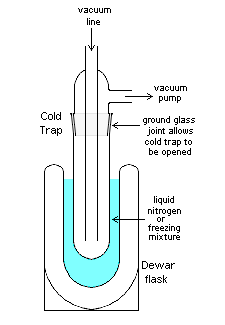

A cryogenically cooled vacuum trap is often added to a vacuum system to improve the performance of the vacuum system and to prevent contaminants in the vacuum line from entering the vacuum pump and causing damage. These traps are often employed on Schlenk lines for degassing solvents or for air-free chemical synthesis. The cold trap is able to condense or freeze low-boiling contaminants and by-products before they enter the vacuum trap.

These cold traps are not without risks. If the trap uses liquid nitrogen as the cooling bath, then any oxygen that enters the vacuum system can be condensed in the trap as liquid oxygen. It appears as a light blue liquid. Mixtures of liquid oxygen with organic contaminants are explosive, and this is a well-known hazard of using liquid nitrogen traps on Schlenk lines. But liquid oxygen isn’t the only concern. In chemical synthesis, any by-products of the reaction will be condensed into the trap. If those by-products are pyrophoric, water-reactive, oxidizing, or otherwise reactive, it can be a cause of fires and explosions as well.

The problem of liquid oxygen condensation in a cold trap can be mitigated by using alternate cooling baths, such as dry ice/acetone baths. See Alternate Cooling Baths for an overview of what other options are available.

Where possible, EHS recommends the use of a blast shield between the user and the cold trap, or the use of a fume hood sash to protect the user in case of unexpected explosion of the trap.