Contents

Approved by Ladan Khandel

Revised 1/24

44.1 Policy

44.2 Scope

44.3 Applicability

44.4 Exceptions

44.5 Roles and Responsibilities

44.6 Definitions

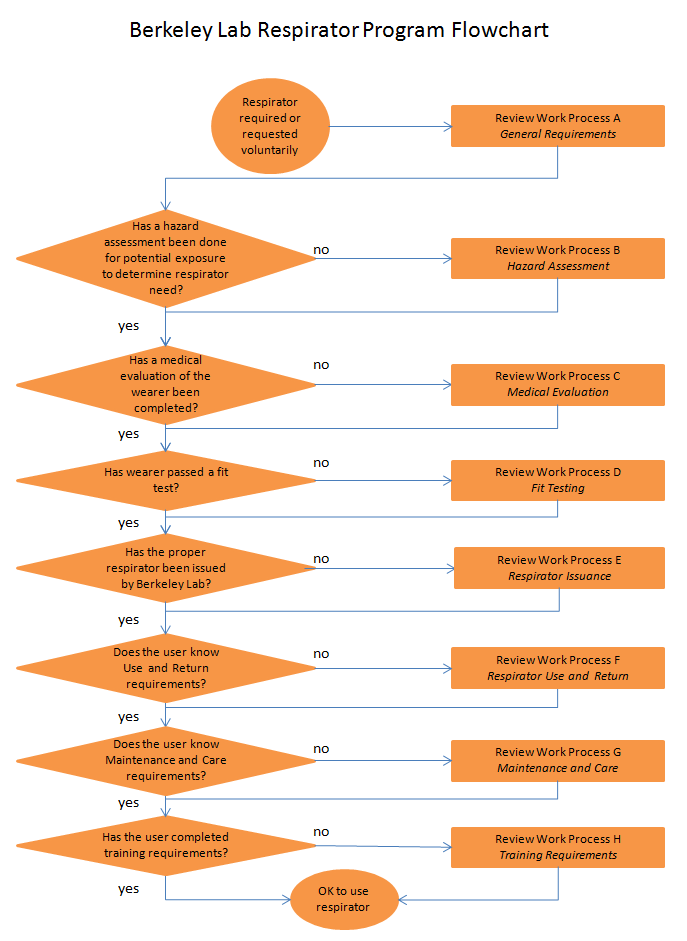

44.7 Required Work Processes

- Work Process A. General Requirements

- Work Process B. Hazard Assessment

- Work Process C. Medical Evaluation

- Work Process D. Fit Testing

- Work Process E. Respirator Issuance

- Work Process F. Respirator Use and Return Work

- Work Process G. Maintenance and Care

- Work Process H. Training Requirements

44.8 Source Requirements

44.9 Reference Documents

44.10 Appendices

- Appendix A. Review of Subcontractor Respiratory Protection Programs

- Appendix B. Assigned Protection Factors

- Appendix C. Quantitative Fit Testing Procedure

- Appendix D. Medical Questionnaire for Respirator Wearers

- Appendix E. Berkeley Lab Respirator Fitting & Issue Record

- Appendix F. Respirator Cartridge and Filter Color Designations

- Appendix G. Selection of Respirators

- Appendix H. Hazard Evaluation Form – Respirator Wearer

- Appendix I. Training Review Guidelines

- Appendix J. Facial Hair Policy

- Appendix K. Emergency Use of Respirators

Note:

🚩🚩 Denotes a new section

🚩 Denotes the beginning of changed text within a section

🛑 Denotes the end of changed text within a section

____________________

44.1 Policy

The Respiratory Protection Program (RPP) ensures that Lawrence Berkeley National Laboratory (Berkeley Lab) employees and subcontractors are not exposed to respiratory hazards by:

- Reducing or eliminating hazards via engineering and administrative controls

- Mandating personal protective equipment (PPE) when engineering controls are not adequate

- Ensuring that respiratory protection wearers are using the correct respirator

- Ensuring that respiratory protection wearers are trained and medically cleared

- Periodically reviewing the RPP for effectiveness

44.2 Scope

Berkeley Lab requires that work environments be maintained to ensure the health, safety, and well-being of Berkeley Lab workers. This document addresses the requirements for respiratory protection of employees, contract employees supervised by Berkeley Lab, and affiliates.

44.3 Applicability

This document applies to Berkeley Lab employees, contract employees, and affiliates. Other on-site workers, such as construction contractors, are required to have similar programs to protect their employees.

44.4 Exceptions

None

44.5 Roles and Responsibilities

|

Role |

Responsibility |

|

UC Berkeley Office of Environment, Health & Safety (EH&S) |

|

|

Environment, Health, and Safety (EHS) Health Services |

|

|

EHS Radiation Protection Group |

|

|

EHS Health & Safety Department |

|

|

Respiratory Protection Program Administrator (and Program Staff) |

|

|

Supervisors/Activity Leads |

|

|

Employees |

|

44.6 Definitions

| Term | Definition |

| Aerosol | Airborne liquid droplets or solid particles |

| ACGIH | American Conference of Governmental Industrial Hygienists |

| American National Standards Institute (ANSI) | An organization that oversees the creation, promulgation, and use of voluntary consensus standards |

| Air-purifying respirator (APR) | A respirator with an air-purifying filter or cartridge that removes specific air contaminants by passing ambient air through the air-purifying element |

| Assigned protection factor (APF) | The workplace level of respiratory protection that a respirator or class of respirators is expected to provide to employees when those employees are properly fitted, trained, and enrolled in the Respiratory Protection Program |

| Atmosphere-supplying respirator | A respirator that supplies the respirator wearer with breathing air from a source independent of the ambient atmosphere and includes Supplied-Air Respirators (SARs) and Self-Contained Breathing Apparatus (SCBA) units |

| CCR | California Code of Regulations |

| CFR | Code of Federal Regulations |

| Cartridge (air-purifying) | A container with a filter, sorbent, catalyst, or any combination thereof that removes specific contaminants from the air drawn through it |

| Cartridge change schedule | A calculation based on objective information and data to ensure that cartridges are changed before the end of their service life |

| Ceiling limit (C) | The airborne concentration that should not be exceeded during any part of the working exposure |

| Contaminant | A harmful, irritating, or nuisance material that is foreign to the normal atmosphere |

| Current Air Quality Index (Current AQI) | The method used by the U.S. Environmental Protection Agency (U.S. EPA) to report air quality on a real-time basis. Current AQI is also referred to as the “NowCast,” and represents data collected over time periods of varying length in order to reflect present conditions as accurately as possible. |

| Dust mask | The common name for a filtering facepiece respirator |

| Emergency situation | Any occurrence such as, but not limited to, equipment failure, rupture of containers, or failure of control equipment that may or does result in an uncontrolled significant release of an airborne contaminant |

| End-of-Service-Life Indicator (ESLI) | An indicator on a respirator cartridge that is certified by NIOSH for a contaminant to indicate when the cartridge service life is ended |

| Exhalation valve | A device that allows exhaled air to leave a respirator and prevents outside air from entering through the valve |

| Exposure assessment | The process of defining exposure profiles and judging the acceptability of workplace exposures to environmental agents. These assessments may be quantitative, semi-quantitative, or qualitative. |

| Facepiece | That portion of a respirator that covers the wearer’s nose and mouth |

| Filter or air-purifying element | A media component used to remove solid or liquid particles from the inspired air |

| Filtering facepiece (disposable dust mask) | A negative pressure particulate respirator with a filter as an integral part of the facepiece or with the entire facepiece composed of the filtering medium |

| Fit test | The use of a protocol to qualitatively or quantitatively evaluate the fit of a particular respirator to a specific person. A fit test must be repeated annually. |

| Gas | A substance which is in the gaseous state at standard temperature and pressure |

| Hazardous atmosphere | Any atmosphere, either immediately or not immediately dangerous to life or health, that is oxygen deficient or that contains a toxic or disease-producing contaminant exceeding Occupational Exposure Limits (OELs) adopted by Berkeley Lab. |

| Hazard evaluation | This refers to completion of the Hazard Evaluation Form (see Appendix H), Baseline Exposure Assessment Form, Qualitative Evaluation through the Comprehensive Health Environmental Safety System (CHESS), or similar form to document potential respiratory hazards. Overall, this process includes a qualitative or quantitative exposure assessment. |

| High Efficiency Particulate Air (HEPA) filter | A filter that is at least 99.97% efficient in removing monodisperse particles 0.3 micrometers in diameter. The equivalent NIOSH 42 CFR Part 84 particulate filters are the N100, R100, and P100 filters. See P100 Filter. |

| Hood | A respiratory inlet covering that completely covers the head and neck and may also cover portions of the shoulders and torso |

| Immediately Dangerous to Life or Health (IDLH) | Any atmosphere that poses an immediate threat to life, would cause irreversible adverse health effects, or would impair an individual’s ability to escape from a dangerous atmosphere. Berkeley Lab employees are not currently authorized to enter or perform work in IDLH atmospheres. |

| Inhalation valve | A device that allows respirable air to enter a respirator and prevents exhaled air from leaving the respirator through the valve |

| Maximum Use Concentration (MUC) | The maximum atmospheric concentration of a hazardous substance from which an employee can be expected to be protected when wearing a respirator, and which is determined by the assigned protection factor of the respirator or class of respirators and the exposure limit of the hazardous substance. The MUC usually can be determined mathematically by multiplying the assigned protection factor specified for a respirator by the Permissible Exposure Limit (PEL), short-term exposure limit, ceiling limit, peak limit, or any other exposure limit used for the hazardous substance. |

| Negative pressure respirator (tight fitting) | A respirator in which the air pressure inside the facepiece is negative during inhalation with respect to the ambient air pressure outside the respirator |

| NIOSH | National Institute for Occupational Safety and Health, which provides a testing approval and certification program for respirators, filters, and cartridges |

| NIOSH approved | Certified for use by the National Institute for Occupational Safety and Health of the U.S. Department of Health and Human Services (DHHS) |

| Occupational Exposure Limits (OELs) | The maximum concentration of an air contaminant to which working people can be exposed for a specified time interval, usually the maximum average exposure allowed throughout an entire eight-hour shift. OELs are typically Permissible Exposure Limits (PELs) or Threshold Limit Values (TLVs), which are also defined in this section. |

| Oil | Any substance that is in a viscous liquid state (“oily”) at ambient temperatures or slightly warmer and is both hydrophobic and lipophilic |

| Oxygen deficient atmosphere | An atmosphere containing less than 19.5% oxygen by volume and 2) an oxygen content below 12.5% (95 mmHg ppO2) at sea level or at an atmospheric pressure less than 450 mmHg (8.6 psi) equivalent to 14,000 ft (4270 m) altitude |

| Pl00 filter | Filter that replaces the HEPAfilter for half-mask and full-face mask non-powered respirators. P100 is the 99.97% efficient oil-proof filter. 42 CFR Part 84 provides for nine classes of filters (three levels of filter efficiency, with three categories of resistance to filter degradation). The levels of filter efficiency indicate minimum filter efficiency in removing particles of approximately 0.3 microns in diameter. |

| Particulate filter designations | Nine designations based on three filter efficiency ratings and three categories of resistance to degradation by oil mist: 99.97% efficient, 99% efficient, 95% efficient Oil Proof P100 P99 P95 Oil Resistant R100 R99 R95 Not Oil Proof N100 N99 N95 |

| Particulate matter | A suspension of fine solid or liquid particles in air, such as dust, fog, fume, mist, smoke, or spray. Particulate matter suspended in air is commonly known as an aerosol. |

| Permissible Exposure Limit (PEL) | The Cal/OSHA permissible exposure limits are exposure levels considered safe for employee exposure in the workplace. Permissible exposure limits for airborne concentrations of hazardous materials are listed in 8 CCR 339 and 8 CCR 5155 for airborne contaminants, and 8 CCR 5096 for physical agents (e.g., noise). |

| Positive-pressure respirator | A respirator in which the air pressure inside the respiratory-inlet covering is designed to be positive relative to the air pressure of the outside atmosphere during exhalation and inhalation |

| Powered Air-Purifying Respirator (PAPR) | An air-purifying respirator that uses a blower to force the ambient air through air-purifying elements and into the inlet covering |

| Pressure-demand respirator | A positive pressure atmosphere-supplying respirator that admits breathing air to the facepiece when the positive pressure inside the facepiece is reduced by inhalation. |

| Resistance | Opposition to the flow of air, as through a canister, cartridge, particulate filter, orifice, valve, or hose |

| Respirator | A device designed to protect the wearer from the inhalation of harmful atmospheres |

| Respiratory inlet covering | That portion of a respirator that forms the protective barrier between the wearer’s respiratory tract and an air-purifying device, breathing air source, or both |

| Respiratory Protection Program Administrator (RPPA) | The individual designated to administer the Berkeley Lab Respiratory Protection Program |

| SAR | Supplied-Air Respirators |

| Self-Contained Breathing Apparatus (SCBA) | An atmosphere-supplying respirator for which the breathing air source is designed to be carried by the wearer |

| Service life | The period of time that a respirator, filter, sorbent, or other respiratory equipment provides adequate protection to the wearer |

| Short-Term Exposure Limit (STEL) | A 15-minute Time-Weighted Average (TWA) exposure that must not be exceeded at any time during a workday |

| Time-Weighted Average (TWA) | The average concentration of a contaminant in air during a specified time period |

| Threshold Limit Value (TLV) | Airborne concentrations of materials to which nearly all workers may be repeatedly exposed without adverse effect. These values are developed and published by the American Conference of Governmental Industrial Hygienists (ACGIH): There are different values established for eight-hour Time-Weighted Averages, Ceilings, and Short Term Exposure Limits Other TLVs are available for non-chemical exposures such as noise and non-ionizing radiation. |

| Voluntary use | Refers to situations in which a respirator may be worn for employee comfort but is not necessary (or relied upon) to prevent overexposures. |

| Wearer seal check | An action conducted by the respirator wearer every time the respirator is donned or adjusted to determine if the respirator is properly seated to the face and, if equipped, to determine proper valve function. |

| WPC-AM | Work, Planning & Control, Activity Manager |

44.7 Required Work Processes

Work Process A. General Requirements

Work Process B. Hazard Assessment

Work Process C. Medical Evaluation

Work Process D. Fit Testing

Work Process E. Respirator Issuance

Work Process F. Respirator Use and Return Work

Work Process G. Maintenance and Care

Work Process H. Training Requirements

Work Process A. General Requirements

- Respirator Selection

- Based on identified hazards, the Program Administrator must maintain and issue respiratory protective equipment when required by Berkeley Lab or used voluntarily (except filtering facepieces and PAPRs).

- Respirators, cartridges, filters, and other components must be NIOSH certified. A variety of models and sizes of respirators must be available to offer employees a choice of equipment to ensure the respirator selected is comfortable and provides an acceptable fit.

- Details on the standard respiratory protection equipment issued by the Berkeley Lab Respiratory Protection Program may be found in Appendix G, Selection of Respirators.

- In addition to the standard respiratory protection equipment maintained for routine use, respirators may be used during hazard assessment or other situations when the exposure cannot be identified or reasonably estimated. In these situations, the atmosphere must be considered IDLH.

- Berkeley Lab employees are not currently authorized to enter or perform work in IDLH atmospheres. If such work were to be authorized in the future, two types of respiratory protective equipment could be used for IDLH atmospheres:

- A full facepiece pressure-demand SCBA with a minimum service life of 30 minutes

- A combination full facepiece pressure-demand airline respirator with auxiliary escape self-contained air supply

- Assigned Protection Factors

- Selection of filters and cartridges must be based on identified hazards and the APFs and MUCs of the respirators selected.

- Assigned protection factors (APFs) define the workplace level of protection that a respirator is expected to provide an employee. The RPP uses the APFs established by OSHA with the following exceptions:

- Berkeley Lab assigns filtering facepiece respirators a protection factor of 1, although they may also be used as part of the complete respirator program for protection from aerosol transmissible diseases.

- Berkeley Lab uses the manufacturer’s APF for PAPR and supplied-air or airline respirators used with helmets and hoods that the manufacturer documents have an APF of 1,000.

- If the manufacturer does not provide APF documentation, an APF of 25 is used. APFs for the most commonly used respirators are summarized in Appendix B, Assigned Protection Factors.

- The level of protection a respirator provides can also be described by the Maximum Use Concentration (MUC), the maximum atmospheric concentration of a hazardous substance from which a respirator is expected to protect an employee.

- Filter and Cartridge Service Life

- Filter and cartridge service life depends on the environment of use. The following guidelines for replacing particulate filters ensure that filters provide the intended protection throughout their service life:

- Particulate filters, when used in the absence of oil aerosols, must be changed when the wearer detects increased breathing resistance or the filter becomes soiled or damaged.

- P-series particulate filters, when used in an environment with oil aerosols, are changed according to the manufacturer’s recommended service life.

- R-series particulate filters, when used in an environment with oil aerosols, must be discarded after 8 hours of use.

- End-of-Service-Life Indicators (ESLI). If appropriate NIOSH-certified cartridges with ESLI are available to protect against a workplace contaminant, the ESLI may be used as an indication that the cartridge is no longer adequate for employee protection.

- Cartridge Change Schedule

- The EHS Health and Safety Department will assess workplace contaminant concentrations as part of the Hazard Evaluation.

- When the contaminants include gases and vapors, the Industrial Hygienist will provide cartridge change information to the respirator wearer, or group of wearers, for each task requiring respiratory protection.

- Cartridge change schedules will be created based on calculated cartridge service life, taking into consideration:

- Nature of the contaminant or mixture of contaminants

- Accuracy of the workplace concentration measurements

- Presence of other organic vapors

- Possibility of high relative humidity

- Potential for cartridge bed migration

- Warning properties of the contaminant

- Any other factors found to be important in the hazard assessment

- Where possible, cartridge change schedules will be developed using the manufacturer’s service life calculators.

- Service life will be calculated using the following guidelines:

- Exposure Level: The established OELs, usually Cal/OSHA PELs, or ACGIH Threshold Limit Values (TLVs) when they are more restrictive, will be used for calculation of the cartridge service life.

- Breakthrough Level: When manufacturers’ service life calculators are used, the allowable breakthrough concentration is 50% of the exposure limit, unless the contaminant concentration is less than ten times the exposure limit, in which case, the allowable breakthrough concentration is 10% of the concentration.

- Safety Factor: A safety factor of 50%, or as determined by the Industrial Hygienist, must be employed for calculations.

- Work Environment: Additional parameters such as work rate, temperature, and relative humidity must be entered according to the work and the work environment.

- Low Boiling Point Organic Vapors: Cartridge bed migration may result in contaminant desorption and migration, even when there is no additional exposure to the contaminant. For contaminants with boiling points less than 65 degrees Celsius, cartridges must be changed after every work shift where exposure occurs, or more frequently if the service life calculation indicates this is necessary. Workers must be instructed about the chemical properties of contaminants they work with. For contaminants with boiling points slightly greater than 65 degrees Celsius, cartridge change frequency may be determined in consultation with the Industrial Hygienist based on the nature of the contaminant and the work environment.

- Warning Properties: Contaminant warning properties are not a reliable measure of cartridge functioning and must not be used to determine cartridge service life. However, workers must be instructed about the contaminant warning properties for the contaminants to which they may be exposed. Warning properties include odor, taste, irritation, burning, and any other indication the contaminant may be present in the air. Workers must be instructed to replace cartridges and contact the industrial hygienist when contaminant odor or any other indicator is detected inside the mask. If the contaminant has poor warning properties, the cartridge change schedule may be modified to provide a greater safety factor.

- Breathing Air. Compressed air cylinders, including SCBA tanks, and breathing air supplied by a compressor may be used at Berkeley Lab. Use of compressed air is subject to the following requirements:

- Compressed air must meet the requirements of CGA Type 1-Grade D breathing air.

- Cylinders of breathing air must meet DOT requirements and have a certificate of analysis that the breathing air meets the requirements for Type 1-Grade D breathing air.

- Compressors that supply breathing air must be constructed to prevent entry of contaminated air into the air-supply system.

- Breathing air supplied by compressors must be tested to verify quality.

- Respiratory Protection Program Evaluation

- Regular reviews of respirator use and program effectiveness will be conducted by the RPPA, or designated reviewer, to ensure that respirator use is in accordance with these requirements, to assess employee views on Program effectiveness, and to identify employee concerns.

- These reviews will also ensure that the Program is being properly implemented.

- Applicable lessons learned will be communicated to respirator wearers. If necessary, respirator wearers will be required to repeat their respirator training.

- In addition, the supervisors of employees who wear respirators must periodically audit respirator storage locations and proper use.

- Any problems found will be corrected. If non-compliances are identified and they are not immediately corrected, they will be entered into the Corrective Action Tracking System.

- Program Audits. In addition to reviews by the RPPA and supervisors, periodic reviews of the Berkeley Lab Respiratory Protection Program will be performed by a knowledgeable person not directly associated with the program.

- Recordkeeping. Records of hazard evaluations, training, and fit testing are maintained in files in the Respiratory Protection Program Training Room. Electronic records of the fit testing are maintained in the EHS Fit Test Database.

Work Process B. Hazard Assessment

Hazard Evaluation

- Before respiratory protective equipment is issued, a Hazard Evaluation is performed by an Industrial Hygienist and/or a Health Physicist if radiation hazards are present.

- Hazard Evaluations may be completed for ongoing programs where the hazards for specific operations can reasonably be predicted for the tasks performed. Hazard Evaluations may also be completed for specific projects. Hazard Evaluations may be completed for a group of employees with similar exposures or for individual workers.

- Hazard Evaluation may find that respiratory protection is necessary if identified hazards cannot be sufficiently reduced or eliminated through engineering or administrative controls. Respirator use may be required by Berkeley Lab:

- When employee exposure may reasonably be expected to exceed an established exposure limit

- When the Hazard Evaluation determines that the added measure of protection of a respirator is desirable due to the variable nature of the work and expected hazards

- During exposure assessment for a task or process reasonably estimated not to be IDLH

- For any other reason specified in the Hazard Evaluation

- Due to the changing nature of the work at Berkeley Lab and the high number of projects that are unique in nature, some groups may prefer to have employees maintain their training in respirator use even when there is no specific project that would require respiratory protection. The Hazard Evaluation Forms for those employees will note that no project requiring respirator use has been identified at the time of respirator issuance. However, potential exposure for these employees will be assessed and appropriate respiratory protection evaluated before any respirator is actually used.

- Hazard Evaluations are documented using the Berkeley Lab Hazard Evaluation Form – Respirator (Appendix H) or an equivalent hazard evaluation. Hazard Evaluations must:

- Include identification of the respiratory hazards that may be present in the workplace

- Include sampling or objective data to estimate employee exposures in the workplace. The objective data will represent the highest contaminant exposures likely to occur under reasonable conditions of processing, use, or handling. Since workplace operations may vary greatly at Berkeley Lab, these objective data may be most important for unique operations. Where possible, and for on-going routine operations, sampling is the preferred method of Hazard Evaluation.

- Include information on the chemical state, physical form, and regulatory limits of contaminants in the employee’s respirator file and reviewed when there is a change in work. Hazard evaluations may reference Berkeley Lab’s Comprehensive Tracking System (CTS) for exposure tracking.

- Indicate whether respiratory protection is required or voluntary. For required and voluntary (except dust masks) respirator use, upon completion of the Hazard Evaluation, the Industrial Hygienist will refer the employee to Berkeley Lab Health Services for evaluation. The Hazard Evaluation will be provided to Health Services.

- For voluntary filtering facepiece (dust mask) respirator use, the employee completes EHS0311, Respirator Awareness (Dust Mask) Training prior to use of filtering facepiece respirators.

- Smoke from wildfires contains chemicals, gases and fine particles that can produce harmful health effects. The greatest hazard comes from breathing fine particles in the air, which can reduce lung function, worsen asthma and other existing heart and lung conditions, and cause coughing, wheezing and difficulty breathing.

- Whenever engineering controls and administrative controls are not feasible or do not reduce outdoor employee exposures to PM2.5 to less than an AQI of 151, exposure can be controlled by respiratory protective equipment.

- When employees are exposed to an AQI equal to or greater than 151 but not exceeding 400, respirators will be provided for employees to use voluntarily.

- When employees are exposed to an AQI of 400 or greater, a respirator will be provided and respirator use is required.

- This section does not apply to work spaces and operations:

- In enclosed buildings or structures in which the air is filtered by a mechanical ventilation system;

- In enclosed vehicles in which the air is filtered by a cabin air filter;

- Where the AQI is 150 or lower;

- Where the AQI is 151 or greater for less than 1 hour during a shift.

- Whenever engineering controls and administrative controls are not feasible or do not reduce outdoor employee exposures to PM2.5 to less than an AQI of 151, exposure can be controlled by respiratory protective equipment.

Work Process C. Medical Evaluation

- Prior to being fitted and trained for respirator use, employees required to wear a respirator and voluntary wearers (excluding employees who are voluntary wearers of filtering-facepiece respirators only) must be medically evaluated to ensure they are capable of wearing a respirator.

- Following completion of a Hazard Evaluation, employees contact Health Services (ext. 6266) at Building 26 for a Respirator Medical Evaluation.

- Upon successful completion of the Respirator Medical Evaluation, Health Services will provide a medical determination of the employee’s ability to wear a respirator, including any restrictions.

- A copy of the signed medical approval will be issued to the employee to bring to their scheduled fit test.

- Annual medical evaluations are not required for most respirator wearers, except as noted below for SCBA wearers. However, if a wearer experiences difficulty in respirator use at any time, he or she must be referred to Health Services for re-evaluation before continuing respirator use. Conditions that indicate a need for re-evaluation, as noted elsewhere in this plan, include:

- Employee exhibits difficulty breathing, shortness of breath, dizziness, or a severe psychological reaction during any phase of annual fit testing

- Employee reports signs or symptoms that are related to respirator use

- Respiratory Protection Program Administrator or Health Services representative finds any indication that the employee may need re-evaluation

- Employee, or his/her Supervisor or Principal Investigator, finds any indication that re-evaluation may be required. This would include any change in employee exposure or stress, physical difficulty in respirator use, or change in work conditions such as physical work effort, protective clothing, or temperature.

- Employee reports or the Supervisor, Line Manager, Health Services, or Respiratory Protection Program Administrator visually observes changes in the employee’s physical condition that could affect respirator fit. This includes facial scarring, dental changes, cosmetic surgery, or a change in body weight. Medical evaluations for SCBA wearers must be repeated on an annual basis.

Work Process D. Fit Testing

- The safe and effective use of respirators with tight-fitting facepieces requires that the respirator be properly fitted to the employee. Respirator Training, EHS0310, is provided on an as-needed basis following completion of a Hazard Evaluation by an Industrial Hygienist or a Health Physicist and successful completion of the Respirator Medical Evaluation by the employee.

- EHS0310 includes fit testing of an appropriate respirator or respirators. The employee must arrange with the Respirator Protection Program Administrator for an appointment for Respirator Training. This training, also known as “fit testing,” is provided through the Health & Safety Department.

- Initial and annual refresher trainings do not differ substantially in content, but the initial training session normally requires more time to complete. Employees should allow about an hour to complete the initial EHS0310 Respirator Training. This training is repeated annually.

- Fit testing is provided for the type of respiratory protection that Hazard Evaluation determines is required. Additional information on respirator selection is contained in the Procedures section of this document. Details on the respirator training, which is also included in EHS0310, are contained in the Training section of this document.

- The following requirements apply to respirator fit testing:

- Fit testing of tight-fitting atmosphere-supplying respirators and tight-fitting powered air-purifying respirators must be accomplished by performing quantitative or qualitative fit testing in the negative pressure mode regardless of the mode of operation (negative or positive pressure) that is used for respiratory protection.

- Prior to issuing a tight-fitting respirator under mandatory use to any employee, the employee must successfully pass a quantitative fit test on that respirator.

- Fit testing is normally done using a PortaCount Plus or PortaCount Pro+ Respirator Fit Tester. An exception may be made on occasions when the PortaCount fit testing equipment is temporarily unavailable, for example, when this equipment is undergoing manufacturer calibration. Qualitative fit testing using isoamyl acetate may be used for fit testing on an interim basis, though other Cal/OSHA compliant means may be employed.

- In most cases the employee will be tested with the mask to be issued using an adaptor for use with the PortaCount instrument.

- Fit testing may be conducted using a surrogate mask, having the same facepiece size and style as the mask to be used. Use of a surrogate mask is required when the respirator to be used is an airline respirator. Surrogate masks may be negative pressure respirators fitted with adapters or they may be probed facepieces.

- Poorly fitted respirators may leak and fail to provide the required degree of protection. It may be necessary to test several models and sizes to identify the best fitting respirator.

- Berkeley Lab requires (see Appendix J) that employees with facial hair that intrudes into the area where the negative or positive pressure respirator seals against the face or that interferes with valve function must not be fitted with (or allowed to use) a tight fitting facepiece respirator.

- Berkeley Lab does not accommodate employees who wish to maintain facial hair that interferes with respirator fit, unless there is a health issue.

- Employees with facial hair who are required to wear a negative or positive-pressure tight-fitting respirator must shave any interfering facial hair so that a respirator can be worn.

- If an employee exhibits any difficulty breathing or has a severe psychological reaction during any phase of the fit testing, that employee must be referred to Health Services for medical re-evaluation.

- Fit testing will not be conducted until it is verified that an employee has a completed WPC-AM work authorization or a hazard evaluation conducted by an Industrial Hygienist indicating respirator use and has been medically approved for respirator use (if applicable).

- Fit testing must be repeated whenever necessary, based on physical changes such as:

- Weight changes of 20 pounds or more

- Significant facial scarring in the area of the face seal

- Significant dental changes (e.g., multiple extractions without prosthesis, or acquisition of dentures)

- Reconstructive or cosmetic surgery

- Any other condition that may affect the facepiece seal

- For more information about the quantitative fit testing procedure using the PortaCount, refer to Appendix C, Quantitative Fit Testing Procedure, Using the PortaCount Plus: Operator Guidelines.

Work Process E. Respirator Issuance

- Program Scope: Required and Voluntary Use

- Respirator use by employees may be required or voluntary. There are two types of voluntary respirator use:

- Voluntary use of filtering facepiece respirators (dust masks)

- Voluntary use of all other respirators

- The type of use is determined by the Hazard Evaluation, which is used to document respirator use.

- Respirator use by employees may be required or voluntary. There are two types of voluntary respirator use:

- Required Use. Where the use of a respirator is required by Berkeley Lab, employees must be enrolled in the Respiratory Protection Program and be subject to all program requirements for respirator issuance, including hazard evaluation, exposure monitoring, cartridge change schedule (if applicable), medical evaluation, fit testing (for tight-fitting facepieces), training, and annual retraining.

- Voluntary Use

- Where the use of the respirator is not required by Berkeley Lab, employees may elect to use a respirator other than a filtering facepiece respirator (dust mask) on a voluntary basis for an extra measure of protection or for personal comfort. In these cases, the employee must also be enrolled in the Respiratory Protection Program and is subject to applicable Program requirements, except that a cartridge change schedule and exposure monitoring are not required.

- There may be instances where respirator use is required for a hazard (for example, exposure to particulate materials that are above an OEL) and the employee also wishes to have additional protection, for example, from nuisance odors. In this case, the use of a respirator is required, but the employee may also choose additional protection on a voluntary basis. This is noted in the Hazard Evaluation.

- Voluntary Use: Filtering Facepiece Respirator (Dust Mask)

- In some cases, where the use of a respirator is not required by Berkeley Lab, an employee may voluntarily use a filtering facepiece respirator (dust mask). In these cases, the hazard will be evaluated by an Industrial Hygienist or the Program Administrator. When the Hazard Evaluation finds that the employee is not required to wear a respirator, voluntary use of a filtering facepiece respirator may be acceptable for personal comfort.

- With the exception of filtering facepiece use for the control of infectious aerosols (EHS0314), the employee voluntarily choosing to use respiratory protection:

- Is not enrolled in the Respiratory Protection Program

- Is not required to be medically evaluated or complete annual fit testing and training (EHS0310)

- Must be trained in the use of the filtering facepiece (EHS0311)

- Must be provided with the information contained in 8 CCR 5144 (see Appendix D)

- Dust masks that are stored properly may be reused provided they have not become damaged, soiled, or breathing has become difficult. If any of the above conditions have occurred or if the dust mask has not been stored appropriately, it must be promptly discarded.

- Clean rooms and laboratories may use NIOSH-approved filtering facepiece respirators to minimize contamination of equipment. When the respirator is used for product protection rather than for employee comfort, it is acceptable to use masks (e.g., surgical masks) that are not approved by NIOSH.

- Respirator Issuance Procedures Overview

- Employees, supervisors, EHS, or Health Services may initiate the respirator issuance process.

- All respirator issuance includes a review of the work process by the EHS Health and Safety Department (or Radiation Protection Group), including determination of whether the use of a respirator is required or voluntary.

- For issuance of respirators other than filtering facepieces (dust masks) for voluntary use, the Industrial Hygienist, Radiation Protection Group (RPG) representative (Health Physicist), Biosafety Professional, or RPPA will complete a Hazard Evaluation Form for the employee to take to Health Services. The employee makes an appointment with Health Services for a Respirator Medical Evaluation.

- Upon successful completion of the Respirator Medical Evaluation, the employee contacts the Respiratory Protection Program Administrator to schedule the Respirator Training (including fit testing).

- For voluntary issuance of filtering facepieces, the employee enrolls in EHS0311 for training.

- For additional information on respirator issuance, employees and supervisors should contact the Respiratory Protection Program Administrator.

Work Process F. Respirator Use and Return Work

- When in Use

- Employees must use and care for respirators issued to them according to requirements listed in the Training Review Guidelines (Appendix I). A copy is provided to each employee during the annual Respirator Training.

- Respirator training includes inspection prior to each use and seal checks to make sure that the valves and face seal are working properly (see Appendix I, Training Review Guidelines).

- Respirators that are damaged or fail to fit properly must not be used and must be immediately removed from service and returned to the EHS Health & Safety Department for evaluation.

- When Not in Use

- When not in use, respirators must be stored to protect against dust, sunlight, extremes of temperature, excessive moisture, or damaging chemicals.

- Respirators should be decontaminated if necessary and allowed to dry before being stored in sealed plastic bags or other sealed containers.

- Employees may clean and decontaminate respirators if facilities are available or at any time bring respirators to the Respiratory Protection Program Administrator for decontamination in the respirator washer.

- Respirators must be stored in a manner that ensures the facepiece shape is not deformed.

- When installing new chemical cartridges, the wearer should mark the date on the side of the new cartridge.

- Wearer must follow instructions as detailed in this program and any additional specific guidance provided to them for cartridge replacement.

- Employees may wear their own prescription contact lenses while wearing a half mask or full facepiece respirator if they choose this option. This option should be evaluated to ensure that the respirator does not interfere with the eyewear, make the employee uncomfortable, or force the employee to remove the eyewear. The employee also may be fitted with prescription lenses that fit inside a full face mask.

- Respirator Return. Respirator return to the Health & Safety Department must be in accordance with the following requirements:

- The respirator must be returned to the industrial hygiene lab if the respiratory protective equipment:

- Malfunctions or is damaged

- Becomes grossly contaminated

- Becomes too dirty or difficult to wipe down or self-clean

- Respirators should be returned in plastic bags and must be labeled accordingly if contaminated with toxic material

- Respirators used for radioisotope protection must not be returned through the mail system and must be decontaminated prior to return. If decontamination is not possible, the mask must be disposed of in accordance with Waste Management Procedure.

- Respirators used by Berkeley Lab employees may be returned to the Industrial Hygiene Lab occasionally for cleaning.

- To return a respirator through the mail system, employees are instructed to put the respirator into a sealed ziplock bag and then into a large manila envelope addressed to: IH Lab, MS26B0097. Employees may also drop masks off at B26, Room 24A.

- The respirator must be returned to the industrial hygiene lab if the respiratory protective equipment:

Work Process G. Maintenance and Care

- Inspection. In addition to the employee’s inspection prior to each use, every respirator must be inspected by the EHS Health & Safety Department when it is returned to the Industrial Hygiene Lab. This involves the following:

- Examining the straps, hoses, valves, gaskets, mask body, and filters/cartridges, as required

- Replacing defective or worn parts

- Avoiding interchanging parts between different brands of respirators, which voids their NIOSH approval.

- Field cleaning of respirators is performed on a regular basis by the wearer by removing cartridges and filters and washing the entire respirator with soap and warm water in a clean area.

- Cleaning/Sanitizing

- When the respirator requires a thorough cleaning and sanitizing, it must be returned to the EHS Health & Safety Department and exchanged for a sanitized mask. Sanitary wipes can be used for additional cleaning before each use.

- The cleaning and sanitizing by the EHS Health & Safety Department must be performed with the use of a respirator washer/dryer system manufactured by Steel Case. This system is specifically designed for washing, drying, and sanitizing a high volume of respirators.

- The washing agent is Masklenze MK-1 (Alkaline Detergent); its major ingredient is potassium metasilicate.

- The sanitizing agent is regular household bleach (5.25% sodium hypochlorite). 7–8 ml of bleach and 15-17 ml of the Masklenze detergent are automatically added to the 2 gallons of water in the washing machine.

- Respirators that are used for quantitative fit testing are cleaned with sanitizing wipes between uses and are cleaned at the end of each day with the automatic respirator washer/dryer system.

- Respirators that are tried for size but not issued to employees may also be cleaned with alcohol wipes but are sanitized with the automatic respirator washer/dryer system before re-use.

- At this time, the only respirators at Berkeley Lab that might be used in emergency situations are Self-Contained Breathing Apparatus (SCBA). It is to be noted that all SCBA equipment at LBNL is the property of, and is maintained and operated exclusively by, the Alameda County Fire Department.

Work Process H. Training Requirements

| Training | Applicability |

| EHS0310, Respirator Training | Employees required to wear respiratory protective equipment must be trained in the selection, care, use and limitations of assigned equipment. Annual training and fit testing (as described in the Fit Testing section of this document) must be completed for tight-fitting and loose-fitting facepiece respirators. |

| EHS0311, Respirator Awareness Training (Dust Mask) | Training of voluntary wearers of filtering facepiece respirators Training required one time only |

| EHS0312, Airline Connected to Air Compressor | Training for wearers of airline respirators connected to air compressors |

| EHS0313, Airline Connected to Air Cylinder | Training for wearers of airline respirators connected to air cylinders |

| EHS0318, Respirator Supervisor Training | Training for supervisors or Activity Leads of employees that are required to wear a respirator Recommended, but not required, for supervisors of filtering facepiece respirators This is a web-based training and must be taken every three years. |

- EHS0310 training may vary depending on the type of respirator to be issued and the nature of the airborne hazard. At a minimum, the training must include:

- Purpose of respiratory protective equipment

- Prerequisites for respirator use, including medical qualification, training, and fit testing

- Different types of respirators, their specific application, selection, and limitations

- Issuance procedure for respirators

- Use of respirators, including field seal checking procedures

- Cleaning and sanitizing procedures

- Proper storage of respirators

- Inspection and maintenance procedures

- Review of the Berkeley Lab Respiratory Protection Training Review Guidelines (Appendix I)

- Viewing a respiratory protection training video/DVD, or equivalent instruction

- Training completion is documented in the EHS Training Database.

44.8 Source Requirements

- California Code of Regulations, Title 8, Division of Industrial Safety, General Industry Safety Orders, Group 16 Control of Hazardous Substances, Article 107 Dusts, Fumes, Mists, Vapors and Gases, Section 5141.1 Protection from Wildfire Smoke. (8 CCR 5141.1)

- California Code of Regulations, Title 8, Division of Industrial Safety, General Industry Safety Orders, Group 16 Control of Hazardous Substances, Article 107 Dusts, Fumes, Mists, Vapors and Gases, Section 5144 Respiratory Protection (8 CCR 5144)

- ANSI Z88.2-2015, Practices for Respiratory Protection

- ANSI Z88.6, Respiratory Protection – Respirator Use – Physical Qualifications for Personnel (See sections related to medical evaluations)

- American Conference of Industrial Hygienists (ACGIH), Threshold Limit Values (TLVs)

- 10 CFR 851, Worker Health and Safety Program

- 10 CFR 851.21(a)(5), Worker Health and Safety Program, Hazard Identification and Assessment

44.9 Reference Documents

| Other Reference | Title | Type |

| DOE Guide 440.1-8, Section 3.3.2.1.5, Implementation Guide for Use with 10 CFR Part 851 Worker Safety and Health Program | Guide | |

| 29 CFR 1910.1000, Subpart Z, Occupational Safety and Health Standards, Limits for Air Contaminants | Federal Regulation | |

| ES&H Manual, Chapter 19 | Personal Protective Equipment | Program |

44.10 Appendices

Appendix A. Review of Subcontractor Respiratory Protection Programs

Appendix B. Assigned Protection Factors

Appendix C. Quantitative Fit Testing Procedure

Appendix D. Medical Questionnaire for Respirator Wearers

Appendix E. Berkeley Lab Respirator Fitting & Issue Record

Appendix F. Respirator Cartridge and Filter Color Designations

Appendix G. Selection of Respirators

Appendix H. Hazard Evaluation Form – Respirator Wearer

Appendix I. Training Review Guidelines

Appendix J. Facial Hair Policy

Appendix K. Emergency Use of Respirators

Appendix A. Review of Subcontractor Respiratory Protection Programs

All subcontractors performing work at Berkeley Lab that requires respirator use must have an equivalent respiratory protection program in accordance with 10 CFR 851, Worker Safety and Health Program. This is accomplished by several means, including the following:

- Procurement packages are sent to all subcontractors, prior to bidding, that indicate the compliance expectations and requirements for subcontractors.

- Prior to the issuance of a “notice to proceed” for a project, any contractor that will be using respiratory protection is required to submit a copy of their written respiratory protection program as well as documentation of fit testing and medical qualification for each worker.

- Documentation is routed through the Construction Safety Manager for review by the Construction Health Manager (or another Industrial Hygienist). The Construction Health Manager confirms that medical submittals indicate that the employee is medically qualified to wear assigned respiratory protection in accordance with 1910.134(e)(5).

- Incomplete or inadequate documentation is rejected and returned to the contractor with a description of the areas needing correction.

- If the causes of rejection are related to medical approval of workers and cannot be worked out with the employer, they will be referred to the Berkeley Lab Health Services group to coordinate resolution with the subcontractor’s physicians or other licensed health care professionals (PLHCPs).

Appendix B. Assigned Protection Factors

Berkeley Lab uses the Assigned Protection Factors (APFs) adopted by OSHA, with the exception of the APF for filtering facepiece respirators. The following chart includes all APFs, including APFs for respirator types that are not typically used at Berkeley Lab. This chart includes the Berkeley Lab adopted APFs for filtering facepiece respirators. These APFs supersede the respirator selection provisions of existing substance-specific standards, except for the respirator selection provisions of the OSHA 1,3-butadiene standard.

Notes:

1 Employers may select respirators assigned for use in higher workplace concentrations of a hazardous substance for use at lower concentrations of that substance or when required respirator use is independent of concentration.

2 The assigned protection factors in Table 1 are only effective when the employer implements a continuing, effective respirator program as required by this section (8 CCR 5144), including training, fit testing, maintenance, and use requirements.

3 Berkeley Lab assigns a protection factor of 1 to filtering facepiece respirators and does not issue them when respiratory protection is required. However, these devices may occasionally be used as part of the comprehensive respirator program to protect Health Care or other essential personnel from aerosol transmissible diseases. In these cases, medical qualification and fit testing are required.

4 This APF category includes half masks with elastomeric facepieces.

5 The employer must have evidence provided by the respirator manufacturer that testing of these respirators demonstrates performance at a level of protection of 1,000 or greater to receive an APF of 1,000. This level of performance can be best demonstrated by performing a WPF or SWPF study, or equivalent testing. Absent such testing, all other PAPRs and SARs with helmets/hoods are to be treated as loose-fitting facepiece respirators and receive an APF of 25.

6 These APFs do not apply to respirators used solely for escape. For escape respirators used in association with specific substances covered by 8 CCR 339, employers must refer to the appropriate substance-specific standards in that subpart. Escape respirators for other IDLH atmospheres are specified by 8 CCR 5144 (d)(2)(B).

Appendix C. Quantitative Fit Testing Procedure Using the Portacount Plus: Operator Guidelines

Fit Testing Protocol

Fit testing is performed according to 8 CCR 5144, Appendix A, Mandatory Fit Testing Procedures. The TSI PortaCount software is set to use the 8 CCR 5144 fit test protocol.

Required forms are located in the front of the file of employee fit testing records. These include:

- Respiratory Fitting and Issue Record (see Appendix E)

- Training Review Guidelines (see Appendix I)

- Course Completion Form

PortaCount Operation

- Turn on the computer and monitor. Open the TSI FitPro software.

- Start the PortaCount instrument and do the Daily Checks to verify PortaCount functioning.

- From the People Database that appears on the screen, select the name of the individual to be fit tested. If necessary, enter a new employee in the database. Fields in the TSI Fit Plus database are populated as follows: COMPANY is Berkeley Lab Division; LOCATION is the employee Mailstop.

- Once a respirator has been selected, press real-time on the PortaCount to view real-time particle concentration inside the mask. When a suitable particle concentration is achieved with the mask being tested, press escape and begin the fit test.

- At completion of the test, the computer automatically saves the fit test data in the cloud database and communicates the data to CHESS.

- To award an employee credit for completing the training, first make sure that they are added to the Berkeley Lab Training (BLT) Group, Respiratory Protection Program. Next, open CHESS and select Add a New Fit Test. Type in the Employee’s name, Save, then select the type of respirator that they were fitted for under Respirator Type and Weight. You do not need to fill in specific make and model information for the respirator. The Portacount database will communicate fit test information to CHESS every 15 minutes.

- For additional information on awarding credit, please refer to CHESS Import FitPro Test Results Instructions

Appendix D. Medical Questionnaire for Respirator Wearers

Appendix E. Berkeley Lab Respirator Fitting & Issue Record

Appendix F. Respirator Cartridge and Filter Color Designations

Color-coded cartridges are available for a variety of air contaminants. In addition to the color-code convention, the specific contaminant groups are printed on the side of the cartridge or filter. The most common cartridge and filter colors are described here:

- HEPA or P100 Filter (Magenta): For filtration of particulates, including asbestos, lead, and silica. The “P” indicates the filter media is “oil-Proof,” and the “100” indicates the filter efficiency is 99.97% of particles at the 0.3 micron size. Magenta color may range from pink to purple.

- Organic Vapor Cartridge (Black): For certain organic vapors. IH will determine service life based on the specific contaminants when respirators are mandatory for employee protection.

- Acid Gas Cartridges (White): For use in atmospheres with acid gas, such as chlorine, hydrogen chloride, sulfur dioxide, hydrogen fluoride

- Organic Vapor and Acid Gas Combination Cartridge (Yellow): For use in atmospheres with organic vapors and acid gas in combination or atmospheres with either organic vapors or acid gas

- Mercury Vapor and Chlorine Gas Cartridge (Orange or Olive): Useful for protection against mercury vapor and chlorine gas

- Multi Contaminant (Olive): For multiple contaminant types. This can include certain organic vapors, acid gases, formaldehyde, ammonia, and methylamine. Olive may be used for other cartridges such as mercury/chlorine. Care should be taken to check the side of the cartridge to verify its approved use.

Appendix G. Selection of Respirators

1. General Discussion

Berkeley Lab offers the respirator types discussed in this appendix. Several different manufacturers’ products are available for the most commonly used respirators. The uses of each respirator are listed. Assigned Protection Factors (APFs) are noted here and are also listed in chart form in Appendix B, Assigned Protection Factors. These APFs supersede the respirator selection provisions of existing substance specific standards, except for the respirator selection provisions of the OSHA 1,3-butadiene standard.

2. Filtering Facepiece (Dust Mask) Respirators

Description: A filtering facepiece respirator, also known as a dust mask, is one with the filter media forming the facepiece itself, or as an integral part of the facepiece. Most filtering facepiece respirators are rated N95, which means the filter media is not oil proof or oil resistant, and it is designed to remove a minimum of 95% of 0.3 micrometer sized particles.

The Laboratory offers filtering facepiece respirators primarily for protection against nuisance particulate material. The use of these masks, commonly known as dust masks, is generally only for work where the mask is not needed to protect against workplace hazards but is for employee comfort. These masks may also be worn when protection is desired to protect equipment or work areas where there is no hazardous atmosphere present.

Unlike other respirators, filtering facepiece respirators may be worn on a voluntary basis. For voluntary use, a hazard assessment must show that respiratory protection is not required for the work operation. Voluntary use of filtering facepiece respirators does not require a Respirator Medical Evaluation or enrollment of the employee in the Berkeley Lab Respiratory Protection Program. However, voluntary wearers of filtering facepiece respirators must complete EHS0311, Respirator Awareness.

(Dust Mask) Training: This training is available to individuals or groups who use these masks, through special arrangement with the RPPA.

An exception to the above guidance is that Health Care workers, or other essential personnel, may be issued filtering facepiece respirators for protection from Aerosol Transmissible Diseases, such as Swine Flu, Bird Flu, etc. In the event that this use is required, a medical evaluation and fit testing is required. Contact the Respiratory Protection Program Administrator for more information.

Advantages: These respirators are lightweight, disposable, comfortable, and inexpensive. They provide protection from nuisance dust. A filtering facepiece may be re-used if desired, until the filter media becomes degraded, until there is a noticeable increase in difficulty breathing, or if it is visibly contaminated. Several different styles are used, typically the filter efficiency and type is N95. The “N” designation indicates the filter media is “Not oil-proof,” and the “95” efficiency indicates the filter media is designed to remove at least 95% of particles at the 0.3 micrometer size.

Limitations: Dust masks offer minimal protection, compared to other types of respirators. Even though the filter media may be rated to remove 95% of 0.3 micrometer size particles, this does not mean that the wearer is protected from 95% of the particulate material. Any air which leaks in the sides of the mask is not filtered at all. The effectiveness of this mask is also compromised when it is worn by an employee with facial hair that interferes with the face to facepiece seal. Like other air-purifying respirators, filtering facepieces offer no protection against oxygen deficient atmospheres, gases, or organic vapors. Other air purifying respirators can protect workers from organic vapors and other gases with appropriate cartridges.

Applications: Low concentrations of nuisance dusts such as pollen, gypsum dry wall, sawdust, and animal dust. Under some circumstances, these may also be utilized for protection from Aerosol Transmissible Diseases. These masks may also be worn voluntarily when it is desirable to protect processes (clean rooms) rather than the individual wearing the mask. Groups who use the filtering facepiece respirator for voluntary protection from nuisance dust include the Facilities Division’s Carpenters, Custodians, Labor Shop, Plant Maintenance Technicians, and Plumbers; the Engineering Division’s Electronics and Instrumentation and Mechanical Engineering employees; the IT Division’s Archivists; and employees who have expressed concern about seasonal allergies.

Assigned Protection Factor 1: Berkeley Lab does not issue filtering facepiece respirators for environments where a hazard is found to be present. Since these masks are not issued to protect from a hazard, and are not fit tested, they are not assigned a protection factor higher than 1. The only exception is when they are used for protection from airborne biological agents as part of the full Respiratory Protection Program that includes medical qualification and fit testing.

3. Negative Pressure Air-Purifying Half-Mask Respirators

Description: The half-mask facepiece has a silicone or other rubber face seal that fits over the nose and under the wearer’s chin. The half-mask air-purifying respirators normally used at Berkeley Lab are negative pressure respirators.

This respirator is fitted with filters or cartridges that purify the air as the wearer breathes. Color-coded cartridges and filters are available for a variety of air contaminants. The most common cartridge and filter colors are described in Appendix F.

Advantages: These respirators can provide a better seal than filtering facepiece respirators.

Because the filters and cartridges can be changed easily, the respirator can be re-used and can be used to protect from a variety of contaminants. Prescription eyewear and safety glasses can usually be worn with the half-mask respirator without compromising the fit. Half-mask respirators are relatively comfortable and are the most commonly selected type of air-purifying respirator.

Limitations: Air-purifying respirators cannot be used for all types of air contaminants, including contaminants whose concentration cannot be reliably estimated, those for which a suitable cartridge is not available, or in oxygen deficient atmospheres. They cannot be used where facial hair interrupts the facial sealing surface. They do not protect the eyes from irritating contaminants.

Applications: Groups who use the half-mask respirator include the Facilities Division’s Carpenters (wood dust, some organic vapors from cabinetry work), Labor Shop (various contaminants depending on work needs, including organic vapors, mercury, and crystalline silica), Plant Maintenance Technicians (asbestos), Plumbers (asbestos, lead, soldering fumes); the Engineering Division’s Electronics and Instrumentation and Mechanical Engineering employees (metals, including lead, and radionuclides); EHS Radiation Protection Group (lead, radionuclides), Health & Safety Department (various, including lead, asbestos, mercury, chlorinated hydrocarbons); Waste Management Group (bulk packing of chemicals); the Materials Science Division (micron sized particulates, metals); and the Earth Sciences Division (crystalline silica).

Assigned Protection Factor: 10

4. Negative Pressure Air-Purifying Full Facepiece Respirators

Description: Air-purifying full facepiece respirators are similar to the half-mask respirators described above in that ambient air is filtered as the wearer breathes. The same cartridges that are used with half masks are available for use with full facepiece respirators to protect against specific hazards. The full facepiece extends around the entire face, covering the wearer’s eyes in addition to the nose, chin, and mouth. These air-purifying respirators are negative pressure respirators.

Advantages: Full facepiece respirators are rated to provide more protection than half-mask air-purifying respirators. When the appropriate cartridge is used, they also protect the eyes from particulates, irritating vapors, mists, and chemical splashes. Newer styles of full facepiece respirators provide ANSI-rated eye and face protection. Some older full facepieces are not rated with this impact protection, so in those instances, a faceshield must be used in addition to the full facepiece mask when impact protection is required. A full facepiece respirator may provide a better fit for some individuals.

Limitations: Air-purifying respirators cannot be used for all types of air contaminants, including contaminants whose concentration cannot be reliably estimated, those for which a suitable cartridge is not available, or in oxygen deficient atmospheres. They cannot be used where facial hair interrupts the facial sealing surface. The wearer’s field of vision may be compromised. When prescription lenses are required by a wearer, a spectacle kit may be provided for the wearer to take to the Laboratory’s optician to have the proper prescription lenses installed. Use of spectacles may require additional time to don and doff the respirator.

Applications: A full facepiece respirator is recommended where a greater degree of respiratory protection is needed or where eye protection from irritants is desirable. Groups who use the full facepiece respirator include the Facilities Division’s Labor Shop (various contaminants depending on work needs, including organic vapors, mercury, and crystalline silica); Engineering Division’s Mechanical Engineering employees (metals, including lead, radionuclides); EHS Radiation Protection Group (lead, radionuclides), the EHS Health and Safety Department (various, including lead, asbestos, mercury, chlorinated hydrocarbons); Waste Management Group (bulk packing of chemicals); Earth Sciences Division (crystalline silica).

Assigned Protection Factor (when quantitatively fit tested): 50

5. Powered Air-Purifying Respirators (PAPRs)

Description: This class of respirators features a battery-powered motor-blower that draws air through a particulate or chemical filter and blows it to the facepiece. The fan/filter unit may be mounted on the wearer’s back or belt or may be integral to the facepiece. Full facepieces and hoods are available. PAPRs may be used with tight-fitting full facepieces, with loose-fitting facepieces, or with hoods or helmets.

Advantages: The major advantage of this type of respirator is the positive pressure provided to the facepiece or hood. This type of respirator may be used during exposure assessment when contaminant concentration is unknown but reasonably expected to be below IDLH concentrations.

Limitations: These units are relatively expensive to purchase and maintain. The battery adds additional weight and must be carried on the wearer’s belt. The battery must be charged prior to use. The filters and cartridges can be bulky and awkward to wear. This class of respirator cannot be used in IDLH atmospheres or atmospheres deficient in oxygen. Heavy exertion may create negative pressure reducing the respirator’s effectiveness.

Applications: These units are useful for work that is more physically demanding; the air blown into the helmet, hood or tight-fitting facepiece cools the wearer. Because some PAPR units are rated with an APF of 1,000, this respirator can be used when a high level of protection is required.

Assigned Protection Factor: 1,000 (tight-fitting full facepiece, hood, or helmet, with manufacturer documentation of performance); APF 25 when manufacturer documentation of performance is not provided; 25 (loose-fitting facepiece); 50 (half-facepiece)

6. Airline Respirators (Continuous Flow or Pressure-Demand Mode)

Description: An airline respirator provides fresh air to the wearer from a compressor or from compressed-air cylinders. The respirator may be a half mask, full facepiece, or loose-fitting facepiece (such as a helmet or hood). Breathing air must meet the requirements of Compressed Gas Association (CGA) Commodity Specification for Air, G-7.1-2011, Grade D. When oil-lubricated compressors are used to provide breathing air, the air is monitored with a carbon monoxide alarm set at 10 ppm. Breathing air couplings must be incompatible with outlets for nonrespirable worksite air (such as “shop air”) and other gas systems. Atmosphere supplying airline respirators may only use Foster and Schrader brand fittings and couplings, and these are Restricted Items and may only be purchased with approval of the Health & Safety Department.

Advantages: This class of respirator provides a high degree of protection against all varieties of air contaminants. Hood models if required and necessary may be worn by personnel with facial hair in accordance with guidelines outlined in Berkeley Lab’s Respiratory Protection Facial Hair Policy. Airline respirators operated in the continuous flow mode can be used in atmospheres that require supplied air.

Limitations: Air is delivered to the mask or hood through a breathing air hose. This hose can be awkward and heavy and may become tangled and crimped. The length of the hose is limited to 300 feet. Breathing air supplied by cylinders or by a compressor must be tested. Continuous flow use: the cost involved in equipping an air compressor can be prohibitive. Pressure-demand use: the air is supplied by a series of cylinders containing breathing air. The system must be maintained, and the MSA Hip-Air Pressure Demand Breathing Apparatus used at Berkeley Lab must be regularly tested and inspected.

Applications: Continuous flow airline systems may be used by employees without further evaluation by Engineering Division Paint Shop employees for sandblasting and paint spray booth activities. Pressure-demand airline systems may be used by the EHS Waste Management Group for special processes when the exposure has not been determined.

Assigned Protection Factor: 1,000 (full facepiece, hood or helmet; continuous flow or pressure-demand) with manufacturer documentation of performance for hoods and helmets. APF 25 when manufacturer documentation of performance is not available.

Note: APF 25 (continuous flow with loose-fitting facepiece)

Note: APF 50 (continuous flow with half mask)

Note: Hood or helmet must ensure the maintenance of a positive pressure inside the facepiece during use.

Note: Pressure demand or other positive pressure SAR, with auxiliary SCBA (escape bottle) may be used for IDLH environments. Berkeley Lab employees are not currently authorized to enter or perform work in IDLH atmospheres.

7. Self-Contained Breathing Apparatus (SCBA)

Description: This type of respirator provides the wearer with clean air from a high-pressure cylinder carried on the wearer’s back. A full face mask is worn. These units are operated in the pressure-demand mode. Air in SCBA units must meet CGA-Type 1 Grade D air requirements.

Advantages: The SCBA offers the greatest degree of protection against all airborne contaminants, including atmospheres deficient in oxygen and IDLH atmospheres. Berkeley Lab employees are not currently authorized to enter or perform work in IDLH atmospheres.

Limitations: SCBA units are expensive to purchase and maintain, require the wearer to carry 20 to 30 pounds of equipment, and provide a limited supply of air, usually 30 minutes. Personnel with facial hair which comes between the respirator sealing surface and the wearer’s face cannot use SCBA equipment.

Applications: For projects for which an air purifying respirator may not be available and, possibly, emergency response use by the Waste Management Group for responding to chemical spills, radiation leaks, etc. In emergency situations an Industrial Hygienist or Health Physicist must be consulted prior to use.

Assigned Protection Factor: 10,000 maximum (pressure-demand or other positive pressure mode).

Appendix J. Facial Hair Policy

In order to assure proper employee protection (and to comply with regulatory requirements) Berkeley Lab has developed this policy. Employees with facial hair between the face and facepiece seal (or that may interfere with valve function) are not allowed to use tight-fitting facepiece respirators. Similarly, the Health & Safety Department will not attempt fit testing of individuals with facial hair that may cause such interference (see also Work Process D, Fit Testing). Additionally, tight-fitting facepiece respirators will not be issued to workers that have such facial hair. Employees with facial hair who are required to wear a negative or positive-pressure tight-fitting facepiece respirator must remain clean-shaven (in facial seal areas) so that a respirator can be worn.

Berkeley Lab is not obligated to accommodate employees who wish to maintain facial hair that interferes with respirator fit, unless there is a medical issue. In cases where an employee does have a medical condition that does not allow maintaining facial hair in a manner that permits tight-fitting facepiece use, EHS Health Services can perform an evaluation, and the worker may be issued an appropriate loose-fitting respirator or provided with other work.

Appendix K. Emergency Use of Respirators

Currently, the sole category of respirators designated for use in emergency situations comprises Self-Contained Breathing Apparatus (SCBA) units. It is to be noted that all SCBA equipment at LBNL is the property of, and is maintained and operated exclusively by, the Alameda County Fire Department.

1. Qualifications

All Berkeley Lab waste handling personnel assigned to work in the HWHF and that have successfully completed the following are specifically qualified to use the SCBAs:

Completion of HAZWOPER training (8 CCR 5192, Part p), Medical evaluations, pursuant to requirements from 8 CCR 5144 and ANSI Z88.6- 2006, Health hazard communication for chemicals in the workplace (this may be done as part of EHS0348 or on the job type training or OJT), Berkeley Lab Respirator training and fit testing (EHS0310), and SCBA training (EHS0315). (Additionally, there are occasional hands-on exercises in which workers don the SCBAs and perform or simulate work activities, though these are not specifically required prior to SCBA use.)

2. Procedures and Requirements

All SCBA qualified workers in the HWHF are assigned respirator facepieces. After every emergency use, the respirator facepieces are to be returned to the the EHS Health and Safety Department’s Respiratory Protection Program to be cleaned and disinfected

In addition to monthly inspections, each unit used in an emergency situation will be checked for proper function before and after each use. Records of inspections will be maintained in the HWHF.

If any respirator fails any of the specified criteria, it will be removed from service and repairs will be performed by a qualified individual or service provider before it is returned to service.

SCBA storage areas will be marked as containing Emergency Use Respirators.

During emergency use, no worker will enter the work area unless another similarly protected worker is also present or located outside the IDLH atmosphere. Communications will be maintained between workers during all emergency use.

_____________________