DRAFT

Contents

Approved by Andrew Peterson

Revised 8/13

54.1 Policy

54.2 Scope

54.3 Applicability

54.4 Exceptions

54.5 Roles and Responsibilities

54.6 Definitions

54.7 Required Work Processes

- Work Process A. Process Flow Diagram

- Work Process B. Receiving and Delivery

- Work Process C. Hand-Carrying or Self-Transport by Hand and Foot

- Work Process D. Self-Transport by Vehicle

- Work Process E. Shipping

- Work Process F. Field Work

- Work Process G. Emergency Action

- Work Process H. Quality Assurance

- Work Process I. Off-Site Storage

- Work Process J. Training

- Work Process K. Security

54.8 Source Requirements

54.9 Reference Documents

Note:

🚩🚩 Denotes a new section

🚩 Denotes the beginning of changed text within a section

🛑 Denotes the end of changed text within a section

___________________

54.1 Policy

It is Berkeley Lab policy to transport hazardous materials in accordance with Department of Transportation (DOT) requirements (specifically, 49 CFR Parts 171-180 and 350-399) as required by the Department of Energy (DOE) Order 460.1C. Where Berkeley Lab deviates from DOT requirements, the Laboratory will generate a Transportation Safety Document as required by DOE and/or obtain a Special Permit from DOT to specifically authorize the deviation.

54.2 Scope

This chapter applies to staff personally moving (“self-transporting”) and/or shipping via a commercial carrier materials that meet DOT’s definitions of hazardous materials.This chapter’s scope excludes self-transporting and shipping of radioactive materials, hazardous materials, and hazardous wastes by the Radiation Protection Group (RPG) and Waste Management Group (WMG) as documented in Berkeley Lab’s DOE-approved Transportation Safety Document and the applicable RPG and WMG implementing documents.

54.3 Applicability

This program applies to all Berkeley Lab employees, affiliates, and subcontractors.

54.4 Exceptions

Not applicable

54.5 Roles and Responsibilities

|

Roles |

Responsibilities |

|

Receiving |

|

|

Shipping |

|

|

Transportation |

|

|

Staff (self-transporting hazardous materials) |

|

54.6 Definitions

| Word | Definition |

| On site | Within the fenced boundaries of the main Berkeley Lab facility, also known as the Hill site |

| Self-transport | The process of an individual personally moving hazardous materials from one Berkeley Lab work location to another Berkeley Lab work location (building to building), either by hand carry or by vehicle. Self-transport is used interchangeably with “moving” or “on-site transfer.” This includes Berkeley Lab employees moving hazardous materials to off-site locations. |

| Shipping | Moving hazardous materials from Berkeley Lab to another location when shipping papers (shipping order, bill of lading, manifest, etc.) are required. This typically applies when Berkeley Lab pays a commercial carrier such as FedEx to move the hazardous materials on the Laboratory’s behalf, but it may apply to Berkeley Lab staff in specific situations. |

54.7 Required Work Processes

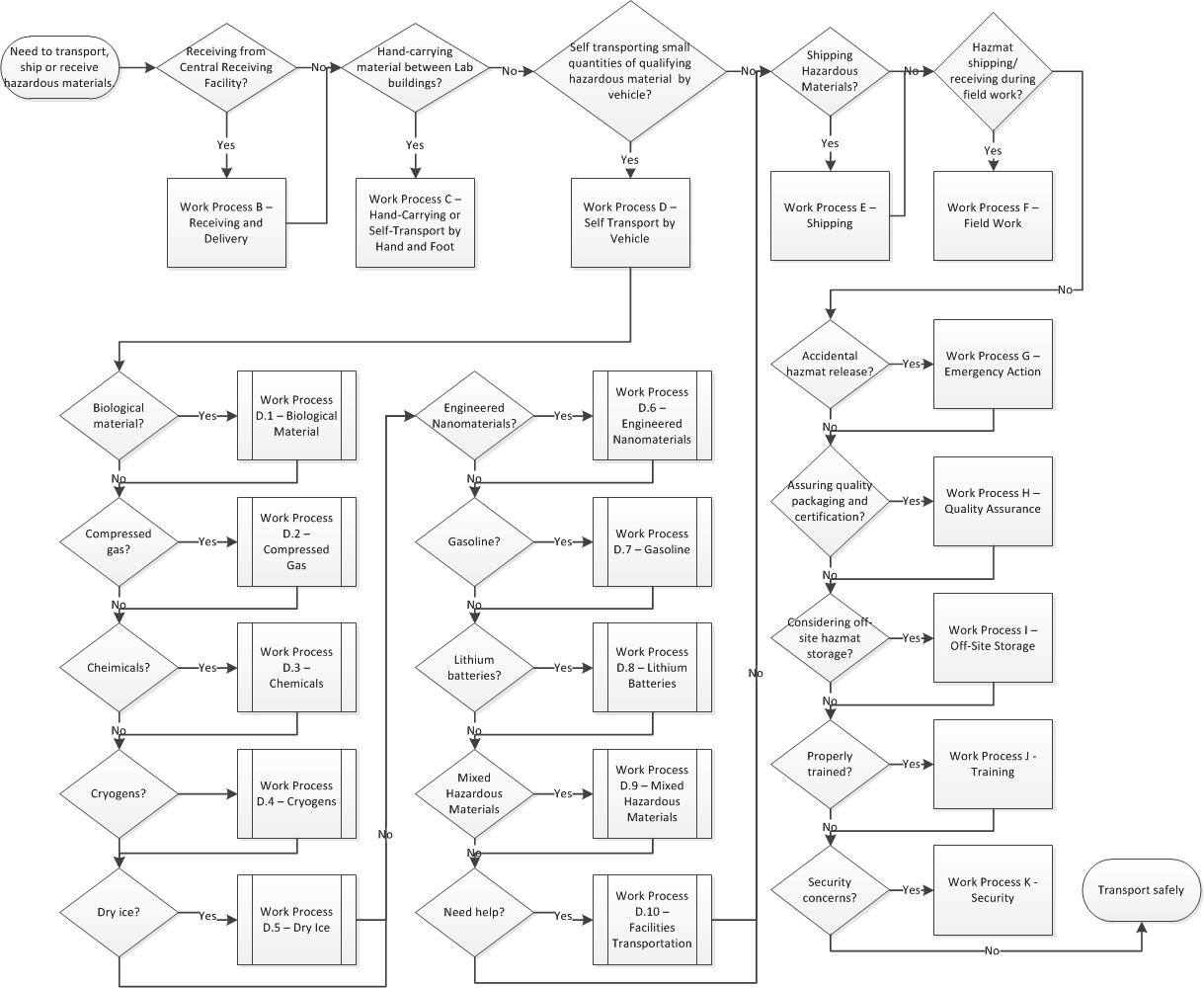

Work Process A. Process Flow Diagram

Work Process B. Receiving and Delivery

Work Process C. Hand-Carrying or Self-Transport by Hand and Foot

Work Process D. Self-Transport by Vehicle

Work Process E. Shipping

Work Process F. Field Work

Work Process G. Emergency Action

Work Process H. Quality Assurance

Work Process I. Off-Site Storage

Work Process J. Training

Work Process K. Security

Work Process A. Process Flow Diagram

Work Process B. Receiving and Delivery

Hazardous materials shipped to Berkeley Lab arrive at a central Receiving facility. Receiving staff inspect incoming packages of hazardous materials for damage according to internal procedures (Work Instruction — Site Services Group, Exception Policy [All Received Material]). Damaged packages are managed according to that work instruction.

Receiving arranges for Facilities Transportation to deliver hazardous material packages to the destination noted on the shipping papers. Facilities Transportation delivers hazardous materials in accordance with DOT requirements, including vehicle placarding.

Note: For packages received on site with delivery locations also on site, Transportation may choose not to generate additional DOT shipping papers for those deliveries, as they were received in a DOT-compliant state and are no longer transported in commerce on public roadways. Transportation will generate DOT shipping papers for packages to be delivered to off-site facilities. Hazardous materials should only be delivered to a laboratory or technical area at which the material will be used. Staff should indicate appropriate delivery locations when purchasing hazardous materials. Facilities Transportation will not leave hazardous material packages in hallways. If the destination is locked, Facilities Transportation returns the package to Receiving and attempts to deliver it at a later date and time.

Compressed gas cylinders and cryogenic liquids may be delivered to designated storage locations by a Laboratory-approved vendor.

Work Process C. Hand-Carrying or Self-Transport by Hand and Foot

Staff may hand-carry or self-transport hazardous materials by hand and foot between buildings and between laboratories separated by hallways within a single building, provided it is safe to do so and can be done without spilling the material. Before handling hazardous materials, staff are required to take EHS0348, Chemical Hygiene and Safety training, or an equivalent course relevant to the hazardous material as determined through the worker’s Job Hazards Analysis (JHA).

Guidance is provided in this section for hand-carrying or self-transportation by hand and foot for:

- Biological/infectious substances

- Chemicals

- Compressed gas cylinders

- Cryogens (including cryogens in elevators)

The following requirements apply in those situations:

|

Hazardous Material |

Requirements |

|

Biological / infectious substances |

|

|

Chemicals |

|

|

Compressed gas cylinders |

|

|

Cryogens |

|

|

Cryogens in elevators |

|

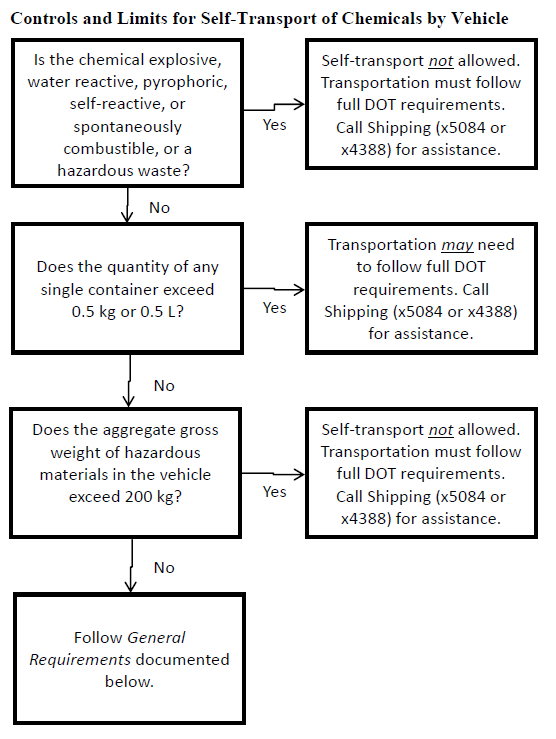

Work Process D. Self-Transport by Vehicle

Staff may personally move or “self-transport” small quantities of most hazardous materials by vehicle. Only trained staff may package hazardous materials for shipment.

Self-transportation has two categories:

- Those hazardous materials that are required to be transported under the full requirements of DOT (including training, vehicle placarding, shipping declarations, etc.)

- Those hazardous materials that can be self-transported in small quantities under less-restrictive DOT requirements (referred to as the Materials of Trade [MOT] exception)

The following table identifies the different DOT hazard classes and the thresholds allowed at Berkeley Lab that distinguish between transportation under full DOT requirements and transportation under MOT requirements.

Berkeley Lab staff may self-transport hazardous materials under the MOT exception limit simply by following the requirements in this section and completing EHS0657 (Self-Transporting Hazardous Materials). For quantities above the MOT exception limit, additional training is required prior to self-transportation of the hazardous materials.

| Hazard | Class/Division | MOT Exception Limit |

| Explosives | 1.1, 1.2, 1.3, 1.4, 1.5, 1.6 | No exception — full DOT requirements apply in all cases |

| Flammable gases | 2.1 | Materials of Trade (below 100 kg per cylinder) |

| Nonflammable, nonpoisonous gases | 2.2 | Materials of Trade (below 100 kg per cylinder) |

| Poisonous gas | 2.3 | No exception — full DOT requirements apply in all cases |

| Flammable and combustible liquids | 3 | Materials of Trade (below 0.5 kg or 0.5 L)* |

| Flammable solids | 4.1 | Materials of Trade (below 0.5 kg or 0.5 L)* |

| Spontaneously combustible material (pyrophoric) | 4.2 | No exception — full DOT requirements apply in all cases |

| Dangerous-when-wet material (water-reactive) | 4.3 | No exception — full DOT requirements apply in all cases (by Berkeley Lab policy) |

| Oxidizers | 5.1 | Materials of Trade (below 0.5 kg or 0.5 L)* |

| Organic peroxides | 5.2 | Materials of Trade (below 0.5 kg or 0.5 L)* |

| Poisonous material | 6.1 | Materials of Trade (below 0.5 kg or 0.5 L)* |

| Infectious substance | 6.2 | Materials of Trade (below 0.5 kg or 0.5 L)* |

| Radioactive materials | 7 | No exception — full DOT requirements apply in all cases (contact RPG, as other exceptions apply) |

| Corrosive material | 8 | Materials of Trade (below 0.5 kg or 0.5 L)* |

| Miscellaneous hazardous materials | 9 | Materials of Trade (below 0.5 kg or 0.5 L)* |

| Other regulated material | ORM-D | Materials of Trade (below 0.5 kg or 0.5 L)* |

| Hazardous waste | N/A | No exception — only Waste Management or an approved vendor may transport hazardous waste |

| Engineering nanomaterials | N/A | Materials of Trade at any quantity(by Berkeley Lab policy) |

*Contact Shipping for any materials that exceed MOT thresholds provided in the table above or for situations that involve transport of hazardous materials with no MOT threshold.

NOTE: It is strongly recommended that staff use government vehicles when transporting hazardous materials. However, as a general rule, activities of a Laboratory employee who is acting within the “course and scope” of his or her employment and in the apparent best interests of Berkeley Lab will be covered by the Laboratory’s self-insurance. This means that a Laboratory employee transporting hazardous materials in a personal vehicle for a Berkeley Lab work-related purpose will be covered by the Laboratory’s self-insurance, absent a showing of some gross negligence on the employee’s part.

If a rental vehicle is being used by a Berkeley Lab employee to transport a hazardous material for a work-related purpose, important qualifications must be met in order for the employee to be covered by insurance should there be an accident. First, the employee MUST use his or her Berkeley Lab corporate account number for the reservation, as well as one of the contracted rental agencies (Enterprise, Hertz, National). In addition, the car rental company agreement may well preclude the transport of hazardous materials, so that should be checked with the rental company in advance.

The following information is applicable only to hazardous materials transported under the Department of Transportation Materials of Trade exception limit! Above the MOT exception limit, contact Shipping.

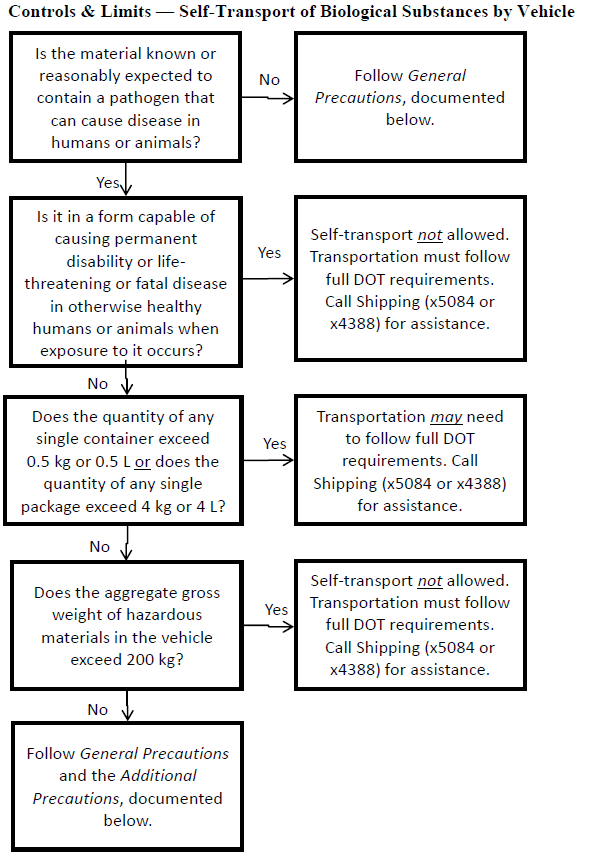

D.1 Biological & Infectious Substances

The following flowchart will help staff determine whether the materials can be self-transported, and which controls must be followed.

General Precautions

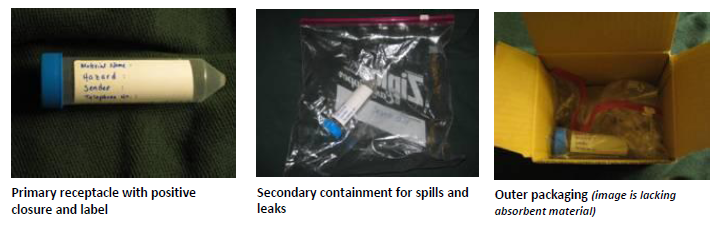

General precautions are best practices designed to minimize the likelihood of spills or leaks and to communicate important hazard information to others. This includes use of primary receptacles and outer packaging (e.g., combination packaging) marked with basic information.

Primary Receptacles

- Primary receptacles should be break-resistant, leak-proof for liquids, and sift-proof for solids. Primary receptacles for liquids should also have a positive means of closure (a screw cap, skirted stopper, metal crimp seal, etc.).

- Primary receptacles should be disinfected as needed for safety.

- Primary receptacles should be placed in a secondary container (i.e., a Ziploc® bag) to contain spills.

Outer Packaging

- Outer packaging should be a strong and tight packaging (ice chest, enclosed laboratory tube carrier, etc.).

- Outer packaging should be securely closed.

- Outer packaging for primary receptacles containing liquids should contain sufficient absorbent material (cellulose wadding, cotton balls, super-absorbent packets, paper towels, etc.) to absorb the entire contents of the inner packaging.

- Packing materials or racks should be used as needed to keep primary receptacles upright, cushion the container, and prevent the container from shifting or damage.

- Outer packaging should be placed inside the vehicle to secure it against shifting during travel.

- Containers for sharps (i.e., sharps containers) should be constructed of a rigid material resistant to punctures and securely closed to prevent leaks or punctures.

Marking

Mark both the inner packaging and outer packaging with:

- Common name or proper shipping name of the material

- Name and phone number of the sender and recipient (if different than the sender)

- Hazard information (including a biohazard label if the material is biohazardous or a statement indicating the material is not hazardous)

Additional Precautions

Staff may self-transport biological substances that are infectious but are not in a form capable of causing permanent disability or life-threatening or fatal disease in otherwise healthy humans or animals when exposure to it occurs,. Staff must follow additional precautions as follows:

- Follow all of the recommendations listed under General Precautions (except for break-resistance and secondary containment, which are still recommended best practices).

- Use the manufacturer’s original packaging, or a packaging of equal or greater strength and integrity.

- Modify your JHA to indicate you self-transport infectious biological substances.

- Simply add a sentence to your description of work until new JHA questions reflect this activity.

- Complete EHS0657 (Self-Transporting Hazardous Materials) (as of May 2013, this is a recommended course only).

- Complete EHS0739 (Biosafety Training for Researchers).

- Inform the driver/passengers about the infectious substances being transported and the safety controls in place.

- As a best practice, print a copy of the Berkeley Lab “Materials of Trade” disclaimer and keep it with the hazardous material during transportation.

Prohibitions

Self-transportation on the shuttle bus of any infectious or potentially infectious biological substance (or a medical/biohazardous waste or any other biological material that may present a detrimental risk to the health of humans or other organisms, either directly through infection or indirectly through damage to the environment) is prohibited.

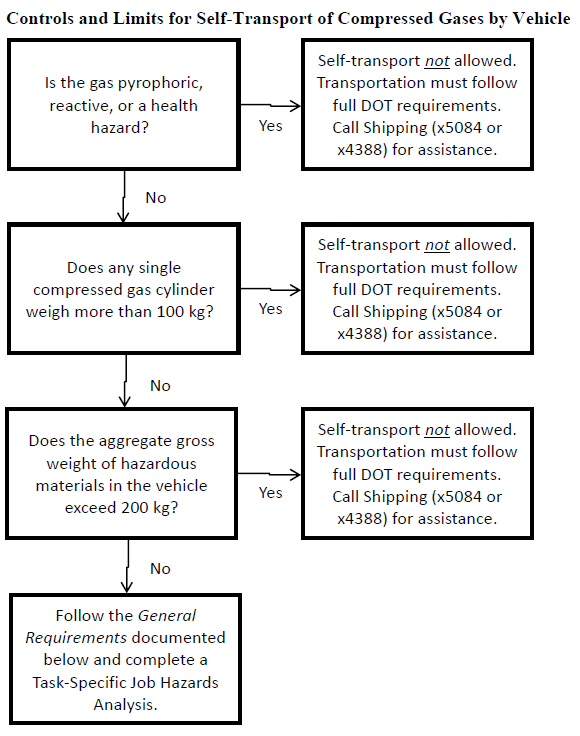

D.2 Compressed Gases

Use the flowchart below and follow the applicable restrictions and guidance.

General Requirements

These requirements are designed to minimize the likelihood of inadvertent movement in a vehicle or a gas leak during transport and to communicate important hazard information to others. These general requirements must be followed:

- Check to see if there is a viable alternative that can transport the compressed gas cylinder on your behalf (such as Shipping or the Laboratory’s compressed gas vendor).

- Modify your JHA to indicate that you self-transport small quantities of compressed gas by vehicle.

- Simply add a sentence to your description of work until new JHA questions reflect this activity.

- Complete EHS0657 (Self-Transporting Hazardous Materials) (currently under development and as of May 2013, this is a recommended course only).

- Package, label, mark, and secure cylinders in a suitable vehicle (i.e., one that has adequate ventilation in the event of a product leak and an adequate method of securing the cylinder during transportation) as described below.

- Take care when lifting a dewar into the vehicle to avoid injury.

- Inform the driver/passengers of the compressed gas cylinders being transported and the safety controls in place.

- Include a copy of the Material Safety Data Sheet during transportation.

- As a best practice, print a copy of the Berkeley Lab “Materials of Trade” disclaimer and keep it with the hazardous material during transportation.

- Complete a task-based JHA for the specific work being performed.

Packaging

No additional outer packaging is required when self-transporting a compressed gas cylinder.

Never move a cylinder with a regulator connected to it. Cylinder valve-protection caps and valve-opening caps must be in place when self-transporting cylinders. As a best practice, lecture bottles and other cylinders not normally equipped with valve-protection caps should be transported in either the original manufacturer’s package or an equivalent container.

Labeling and Marking

Compressed gas cylinders must have a diamond-shaped label indicating the hazard class. This will be a Division 2.1 (flammable gas) or Division 2.2 (nonflammable, nonpoisonous gas) label such as the example below.

Compressed gas cylinders must be marked with the full, non-abbreviated common name of the hazardous materials to identify the material it contains. It must also be marked with the “UN” number if the contents are regulated hazardous materials (typically on the shoulder label with the hazard class information) and the amount of the material contained (in metric units). As a best practice, include the owner and the recipient’s name and phone number with the cylinder.

Examples of cylinder shoulder label with common name, hazard class and UN number

Marking

Compressed gas cylinders must also be marked by the cylinder manufacturer or retester with the last hydrostatic test date of the cylinder, which is usually required every five years. This will include a calendar year stamped on the top of the cylinder. If the cylinder has not been recertified within the past five years, do not self-transport the cylinder, and contact the cylinder vendor for removal.

Example of hydrostatic testing markings (last tested 2010, previously 2004, 1998 & 1993)

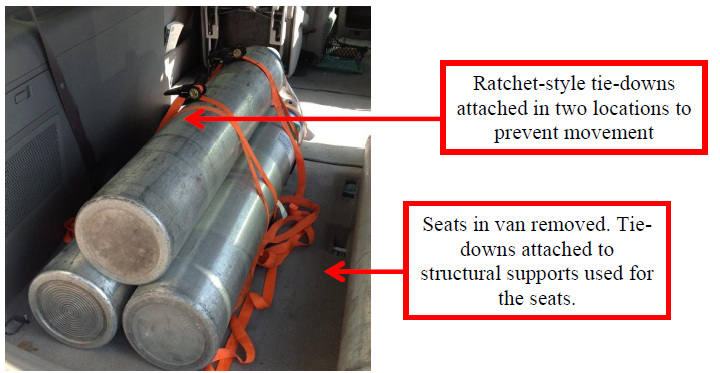

Securing

Cylinders must be adequately restrained during self-transportation so they are not free to move while the vehicle is in motion. The exact method of restraining the cylinder will vary, depending on vehicles and cylinder type, and this information will be included as part of the additional work authorization. In practice, however, this means the vehicle must have tie-down points where ratchet-style tie-down straps or other robust types of restraints can be attached (see photo for an example). Bungee cords and seat belts are NOT adequate for securing cylinders.

If possible, secure and transport compressed gas cylinders in the back of a government pickup truck. If transporting pressurized cryogens, transport is limited to the open bed of a pickup truck.

Example of hydrostatic testing markings (last tested 2010, previously 2004, 1998 & 1993)

Task-Based Job Hazards Analysis

Self-transporting compressed gas cylinders in a vehicle must be covered by a task-based JHA (this requirement does not apply to staff who are fully trained to DOT requirements and follow all of the DOT shipping requirements).

The task-based JHA must document how the specific cylinder(s) will be secured in the specific vehicle and the controls used to prevent leakage, oxygen displacement, or a potentially dangerous atmosphere. Berkeley Lab bases these controls on the Compressed Gas Association (CGA) Position Statement (PS-7), Safe Transportation of Cylinders in Passenger Vehicles.

The controls listed in the work authorization should include these requirements when they are applicable:

- Keep a copy of the manufacturer’s Material Safety Data Sheet in the vehicle as well as a copy of the work authorization.

- Use a government truck and transport the cylinders in the bed of the pickup truck (if this is a feasible option).

- Ensure the cylinder is properly packaged, marked, labeled, and secured.

- Listen for leaks — do not transport a leaking cylinder.

- Visually inspect the cylinder for dents, gouges, or pits.

- Ensure that the cylinder valve is securely closed.

- Ensure that the valve-protection device, where provided, remains in place until the cylinder is ready for use.

- Flammable gases, such as propane, should not be transported in the same vehicle with any containers of oxygen or other oxidizing materials.

- Maintain maximum ventilation in the area where the cylinder is stored (i.e., store in the bed of a pickup, keep windows open, etc.).

- Take a route that is most direct, with no unnecessary intermediate stops (gas stops, bathroom breaks, etc., being “necessary” stops).

- Be aware that environmental conditions such as heat exposure may cause the temperature of the cylinder to rise to excessive levels that could lead to a release of product even if the ambient temperature is relatively low.

- Always maintain adequate fresh air ventilation and ensure that container vents (if present) are not blocked or covered.

- Transport liquefied flammable gas cylinders in the upright position.

- Do not put cylinders in trunks of cars or unventilated areas of passenger vehicles if oxygen deficiency or explosive atmosphere is a potential risk.

- When the destination is reached, promptly remove the cylinder from the vehicle.

Contact the EHS Haz Mat transportation subject matter contact (ext. 8128) to assist with this process.

Prohibitions

Self-transportation of any compressed gases on the shuttle bus is prohibited.

D.3 Chemicals

Use the flowchart below and follow the applicable restrictions and guidance.

General Requirements

General requirements are designed to minimize the likelihood of spills and leaks and to communicate important hazard information to others. These general requirements must be followed:

- Check to see if there is a viable alternative such as using Shipping resources.

- Modify your JHA to indicate that you self-transport small quantities of hazardous materials by vehicle.

- Simply add a sentence to your description of work until new JHA questions reflect this activity.

- Complete EHS0657 (Self-Transporting Hazardous Materials) (currently under development and as of May 2013, this is a recommended course only).

- Complete EHS0348 (Chemical Hygiene and Safety) training or an equivalent course.

- Package, mark, and secure chemical containers as described below.

- Inform drivers/passengers of the hazardous materials being transported and the safety controls in place.

- Include a copy of the Safety Data Sheet during transportation.

- As a best practice, print a copy of the Berkeley Lab “Materials of Trade” disclaimer and keep it with the hazardous material during transportation.

Packaging and Marking

Hazardous materials must be packaged to protect them from damage, to contain leaks, and to communicate information to the public. To achieve these goals, packaging must include:

Primary receptacles that are:

- Leak-tight for liquids and sift-proof for solids

- Securely closed

- Marked with the full, non-abbreviated common name or proper shipping name of the hazardous materials (equivalent methods may be used for primary receptacles that are too small for this)

Outer packaging that is:

- Packaged to secure the primary receptacles against shifting and protect it from damage

- Equivalent in strength and integrity to the manufacturer’s original packaging

- Marked with the full, non-abbreviated common name of the hazardous materials

- As a best practice, staff should also label the receptacles with the owner and recipient’s name and number.

- In addition, sufficient (nonreactive) absorbent materials should be included in the outer packaging to absorb the entire contents of the primary receptacles should a spill occur.

Secondary containers should be used to help contain spills and leaks from the primary receptacles. When used, secondary containers must be chemically compatible with the hazardous materials.

Securing

Staff should use best judgment on where to place the completed package within the vehicle. Ideally this will be in the bed of an open pickup truck, provided the package can be adequately secured. In some cases, however, the optimal location will actually be inside the cab of the vehicle, as it is easier to monitor the package, windows can be rolled down for ventilation, and there are “nooks” between the front and back seats that may be used to help secure and protect the package.

Prohibitions

Self-transportation of any hazardous materials on the shuttle bus is prohibited.

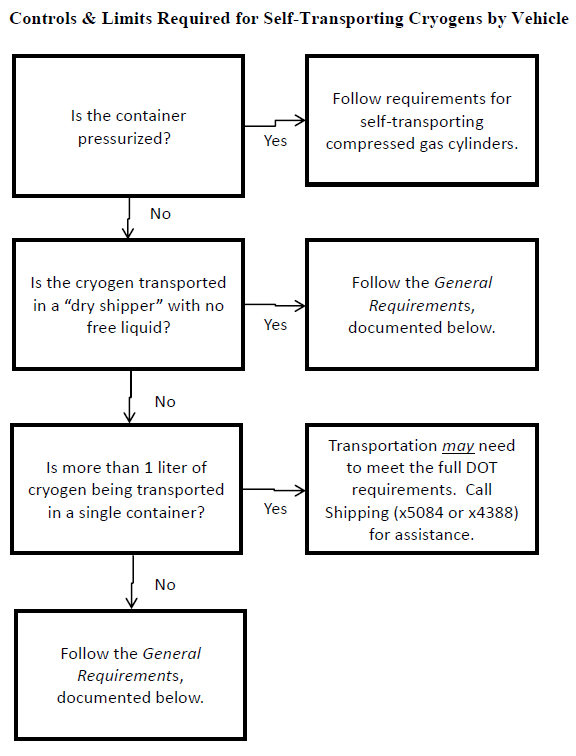

D.4 Cryogens

Use the flowchart below and follow the applicable guidance.

General Requirements

General requirements are designed to minimize the likelihood of spills and leaks and to communicate important hazard information to others. These general requirements must be followed:

- Check to see if there is a viable alternative such as using Shipping resources.

- Modify your JHA to indicate that you self-transport small quantities of hazardous materials by vehicle.

- Simply add a sentence to your description of work until new JHA questions reflect this activity.

- Complete EHS0657 (Self-Transporting Hazardous Materials) (currently under development and as of May 2013, this is a recommended course only).

- Complete EHS0170 (Cryogen Safety).

- Package, mark, and secure containers as described below.

- Take care when lifting a cylinder into the vehicle to avoid injury.

- Inform driver/passengers of the cryogens being transported and the safety controls in place.

- Include a copy of the Safety Data Sheet during transportation.

- As a best practice, print a copy of the Berkeley Lab “Materials of Trade” disclaimer and keep it with the hazardous material during transportation.

Packaging, Marking and Securing

- Receptacles must be constructed with double walls, and the space between the walls must be vacuum insulated (receptacles must be dewars).

- Receptacles must be transported in an outer packaging with sufficient cushioning and absorbent materials to protect the receptacle from damage. (Outer packaging is not required for dry shipper containers.)

- Receptacles must be marked with the owner’s information, including a phone number.

- Receptacles must be placed in an open area (i.e., pickup truck bed) of the vehicle and secured against movement during transportation.

Prohibitions

Self-transportation of cryogens on the shuttle bus is prohibited. Cryogens in unpressurized receptacles cannot be transported inside an enclosed part of a vehicle. “In” a vehicle means inside a vehicle cab, a covered bed, enclosed cargo area, or other enclosed area of the vehicle.

D.5 Dry Ice

Dry ice is regulated as a hazardous material if shipped by air or water. Contact Shipping for any shipments that include dry ice (ext. 5094, ext. 4388, or shipping@lbl.gov). Special labeling on the package is required.

Dry ice is not regulated as a hazardous material when simply transported in a vehicle. Do not place dry ice inside outer packaging that is gas-tight. Transport packages with dry ice in the bed of a pickup truck if feasible. If packages with dry ice must be transported inside a vehicle, roll down all the windows during transport and minimize the amount of time the dry ice is inside the vehicle.

D.6 Engineered Nanomaterials

Engineered nanomaterials are not considered hazardous materials by the Department of Transportation. Berkeley Lab, however, does apply the same controls required for chemicals to unbounded engineered nanomaterials. Follow the requirements for self-transporting or shipping chemicals.

The following are the only differences:

- There is no quantity limit for self-transporting unbound engineered nanomaterials.

- The outer packaging must also contain the words, “Nano-scale: This material’s toxicity, reactivity, and other hazards may be greater than its macro-sized forms.”

D.7 Gasoline

Gasoline canisters are subject to the same transportation and shipping controls as chemicals. Please follow the requirements for self-transporting and shipping chemicals.

The following are the only differences:

- A “small” quantity of gasoline is defined as 8 gallons. Staff may transport up to 8 gallons of gasoline by vehicle. Beyond 8 gallons, additional training and controls are required before the gasoline can be transported.

- The canister containing the gasoline must be of a DOT- or OSHA-approved metal or plastic.

- Containers must be transported in the open bed of a truck.

Note: This does not refer to the gasoline in the gas tank of the vehicle.

D.8 Lithium Batteries

Lithium batteries are considered hazardous materials when shipped by air. Notify Shipping for any shipments that include lithium batteries.

Note: If you need to transport personal-use lithium batteries by air, effective January 1, 2008, you may not pack spare lithium batteries in your checked baggage. You may pack spare lithium batteries in your carry-on baggage.

Lithium batteries are not regulated during self-transportation.

D.9 Mixed Hazardous Materials

In some cases, staff may need to self-transport or ship hazardous materials from different hazard classes, for example, a shipment with a radioactive material, a chemical component, and a waste component.

Each hazardous material must be handled separately and in accordance with the guidance provided in these Web pages. A few important points to keep in mind:

- Radioactive materials cannot be shipped with any other materials, including nonhazardous items like notebooks. If you need to ship other hazardous materials in addition to radioactive materials, ship them separately. Contact your assigned Radiological Control Technician and/or Health Physics (https://ehswprod.lbl.gov/rpg/who_to_call.shtml) to assist with radioactive material shipments.

- Hazardous, biohazardous, medical, and radioactive wastes can only be shipped by Berkeley Lab WMG staff. Submit a requisition (http://www.lbl.gov/ehs/waste/index.shtml) or contact a Generator Assistant (http://www.lbl.gov/ehs/waste/wm_assistant.shtml) for assistance.

Shipping (ext. 5084, ext. 4388, or shipping@lbl.gov) can assist with shipment of all hazardous materials (except for radioactive materials managed by RPG and hazardous wastes managed by WMG).

D.10 Facilities Transportation

Contact Facilities Transportation for assistance with hazardous materials transportation. Requests for assistance with hazardous materials transportation should be sent directly to Shipping (ext. 5084, ext. 4388, or shipping@lbl.gov). For compressed gases and pressurized cryogen dewars, the Laboratory’s vendors such as Praxair, Airgas, and Matheson Tri-Gas may also transport these hazardous materials.

Facilities Transportation will package materials to DOT specifications before transport. Facilities Transportation will use specification packaging materials, which are the types of packaging materials also used for shipping hazardous materials.

Work Process E. Shipping

Only trained staff may package hazardous materials and offer them for shipment.

Shipping of hazardous materials is subject to DOT regulations as well as other regulatory restrictions (such as International Air Transport Association [IATA]/International Civil Aviation Organization [ICAO]) and commercial carrier restrictions (such as those imposed by FedEx, UPS, etc.). It is Berkeley Lab policy to follow all applicable federal and DOE shipping requirements.

Staff must process Berkeley Lab hazardous material shipments through NetShip to initiate the shipping process. Shipping staff will prepare and offer the hazardous material packages for shipment. Shipping staff are trained to DOT requirements and follow packing instructions provided by DOT, IATA, and other applicable organizations when packaging hazardous materials for shipment.

Shipping staff will complete a checklist (different checklists for ground and air) with each shipment to ensure each hazardous material shipment meets applicable requirements.

Work Process F. Field Work

Self-transport of hazardous materials to and from the field follows the same requirements documented in this program. Shipping to the field follows the normal shipping process at Berkeley Lab.

Note: Hazardous and radioactive wastes cannot be transported or shipped back to Berkeley Lab or to any other destination by researchers. Hazardous and radioactive wastes must be managed directly at the point of generation in the field and must be transported by an authorized hazardous waste vendor.

If hazardous materials must be shipped from the field, contact Shipping (ext. 5094, ext. 4388, or shipping@lbl.gov) as early as possible to plan for this activity. Depending on the specific activity, the individual responsible for the return shipping may need additional training and additional controls may be required.

Work Process G. Emergency Action

If an accidental release of hazardous materials occurs during transportation, the driver must take the following actions:

- As the first priority, protect life and property by whatever means available.

- If the material is flammable, keep all flames and sparking devices away.

- Avoid breathing vapors of spilled material; stay upwind.

- Keep non-emergency people and traffic away.

- If the severity of the accident or spill warrants it, call 7911 from a laboratory phone or 911. Provide as much information about the release as possible. When emergency responders arrive on scene, provide them with a copy of the Safety Data Sheet or inform them verbally of the hazardous materials.

- Contact your supervisor to report the incident.

- Contact (510) 486-6999 and ask for an EHS representative to report the incident.

Work Process H. Quality Assurance

Both Facilities Transportation and Shipping use specification packaging materials to package, transport, and ship hazardous materials. This packaging is identified by the UN specification marking on the exterior of the packaging materials. Packaging materials must be purchased from an established, reputable vendor. Certification test reports provided with the specification packaging are kept on file.

In most circumstances, Berkeley Lab will purchase the most robust packaging material available (e.g., variation packaging for packing group I, II, and III). In some cases, lower-rated UN specification packaging may be purchased and used if the lower-rated UN specification packaging material is allowed by DOT for the particular shipment.

Work Process I. Off-Site Storage

Berkeley Lab does not allow storage of hazardous materials at off-site storage facilities. Through the Transportation Authorization process in the Work Request Center, equipment custodians are responsible for certifying that the equipment is free of hazardous materials. EHS is available to assist with this inspection. The EHS Health and Safety Representative is the best contact to initiate this process.

Work Process J. Training

Training is required for employees, who during the course of their work directly affect hazardous materials transportation safety. This includes employees who:

- Load, unload, or handle hazardous materials to or from vehicles that enter highway commerce

- Inspect, mark, maintain, recondition, repair, or test a package, container, or packaging component that is represented, marked, certified, or sold as qualified for use in transporting hazardous materials in commerce

- Prepare hazardous materials for transportation in commerce

- Are responsible for safety of transporting hazardous materials in commerce

- Operate a vehicle used to transport hazardous materials

The following courses apply to staff involved in hazardous material self-transportation and shipping:

| Group (when applicable to the specific function) | Initial Training | Refresher Training |

| Supervisory Staff (of Shipping, Receiving, and Transportation staff involved in hazardous materials transportation) | MAT0002 (Basic DOT Hazardous Material Transportation Training) or General Awareness and Function Specific training (1:1 training specific to task) | MAT0003 (Hazardous Material Transportation Retraining) every 3 years or General Awareness and Function Specific training (1:1 training specific to task) |

| Receiving | MAT0002, EHS0477 (General Awareness — Radioactive Package Receiving) | MAT0003 every 3 years |

| Shipping | MAT0002, MAT0004 (IATA Transport of Dangerous Goods by Air Training) | MAT0003 every 3 years, MAT0004 every 2 years |

| Staff (other than Shipping that may be participate in shipping hazardous materials) | General Awareness and Function Specific training (1:1 training specific to task) | |

| Staff self-transporting MOT quantities of hazardous materials | EHS0657 (Self-Transporting Hazardous Materials) | |

| Transportation | MAT0002 | MAT0003 every 3 years |

In addition, staff are required to take safety training specific to the hazards they are potentially exposed to, such as:

- EHS0348 (Chemical Hygiene and Safety) (or an applicable course) for staff working with or near hazardous chemicals

- EHS0739 (Biosafety Training for Researchers) for staff working with or near biological materials

- EHS0170 (Cryogen Safety) for staff working with cryogens

- EHS0171 (Pressure Safety) for staff working with pressure vessels

- EHS0473 (Radiological Worker II) for staff handling radioactive material that is not 100% packaged per DOT/IATA

Training is administered through Berkeley Lab’s Job Hazards Analysis process.

Work Process K. Security

Security of hazardous materials transportation and shipping is addressed in the Berkeley Lab Facilities Division Site Logistics Department Security Plan (Shipping, Receiving, Transportation), November 2008.

54.8 Source Requirements

- Department of Transportation, 49 Code of Federal Regulations, Section 171-180 and 350-399

- International Air Transportation Association, Dangerous Goods Regulations (current version)

- Department of Energy Order 460.1C, Packaging and Transportation Safety

54.9 Reference Documents

- Berkeley Lab Facilities Division — Procedure LOGIS-007, Shipping — Domestic and International Shipments

- Berkeley Lab Facilities Division — Site Logistics Department Security Plan (Shipping, Receiving, Transportation), November 2008

- Work Instruction — Site Services Group, Exception Policy (All Received Material)

- Berkeley Lab EHS Waste Management Group and Operational Health Physics Group, Transportation Safety Document, Rev. 1, January 18, 2006

- ES&H Manual, Chapter 26, Biosafety

- ES&H Manual, Section 4.7, Chemicals

- ES&H Manual, Chapter 7, Pressure Safety and Cryogenics

- ES&H Manual, Chapter 29, Safe Handling of Cryogenic Liquids

- ES&H Manual, Chapter 21, Radiation Safety

- PUB-5341, Chemical Hygiene and Safety Plan

- Biosafety Manual

- Special Permit Authorization DOT-SP 12998, Expiration March 31, 2014

_____________________