Contents

Approved by Keola Baclayon

Reviewed 10/25

18.1 Policy

18.2 Scope

18.3 Applicability

18.4 Exceptions

18.5 Roles and Responsibilities

18.6 Definitions

18.7 Required Work Processes

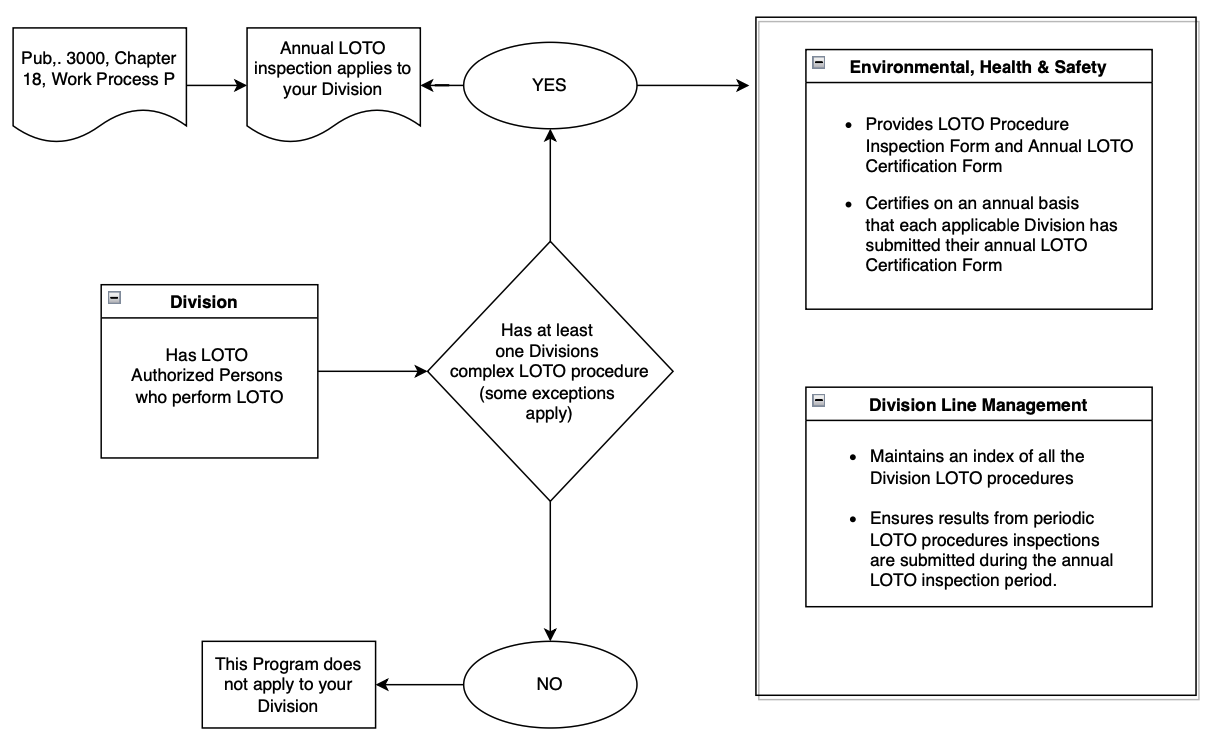

- Work Process A. LOTO Program Quick Reference Map

- Work Process B. Basic LOTO Rules

- Work Process C. Cord-and-Plug Equipment

- Work Process D. Simple LOTO

- Work Process E. Complex LOTO

- Work Process F. Complex LOTO Requiring a Responsible Individual

- Work Process G. Group LOTO With a Lockbox

- Work Process H. Tagout Only

- Work Process I. Subcontractor LOTO Permit

- Work Process J. Shift Changes and Transfer of Control

- Work Process K. Temporary Partial Restoration

- 🚩🚩Work Process K.1. Temporary Connections to Distribution or Premises Electrical Systems🛑

- Work Process L. LOTO Hardware

- Work Process M. Training and Authorization

- Work Process N. Developing LOTO Procedures

- Work Process O. Special Condition LOTO Lock Removal

- Work Process P. Periodic Inspections of LOTO Procedures

- Work Process P.1. LOTO Program Assurance Plan

- Work Process Q. Physical Separation

- Work Process R. Interlock Systems

- Work Process S. Administrative Control

- Work Process T. LOTO Coordination

18.8 Source Requirements

18.9 Reference Documents

18.10 Appendices

- Appendix A. LBNL LOTO Procedure Process

- Appendix B. Written LOTO Procedure Alternate Format

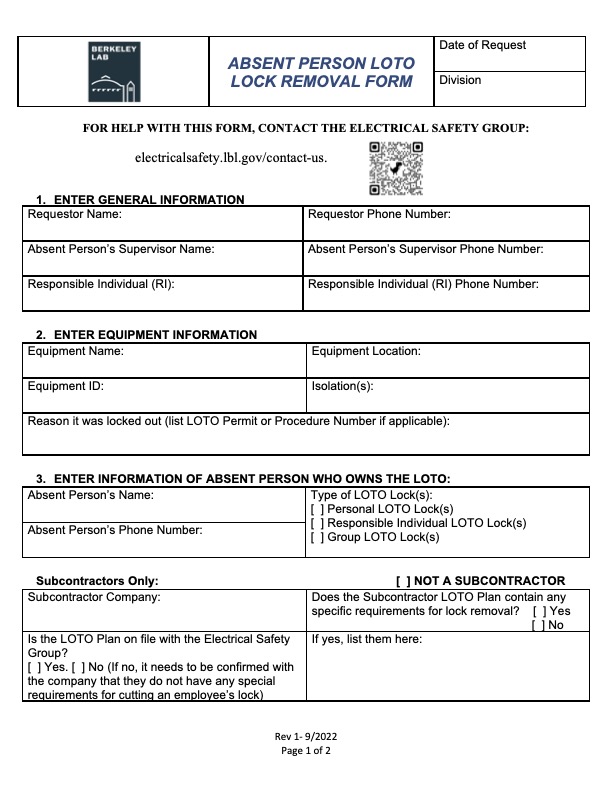

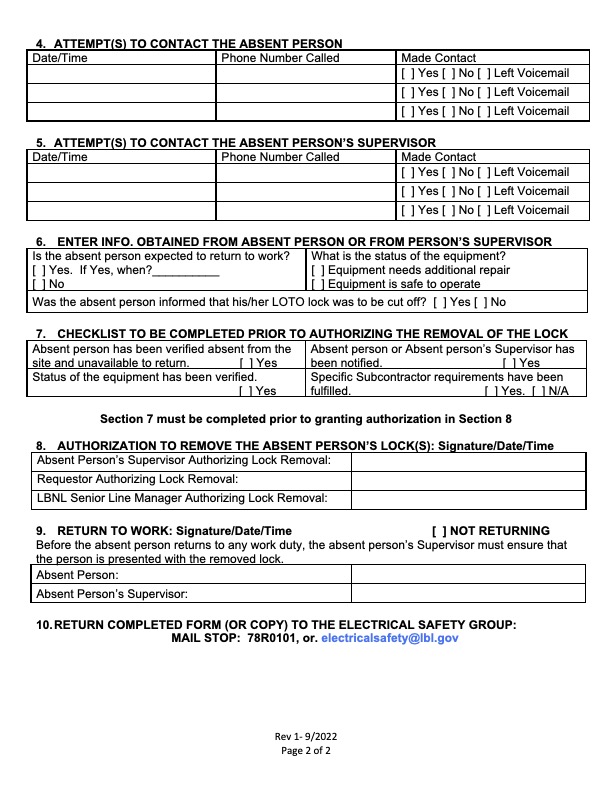

- Appendix C. Absent Person LOTO Lock Removal Form

Additional Process Flows and Training Aids can be found here: https://electricalsafety.lbl.gov/loto/

Note:

🚩🚩 Denotes a new section

🚩 Denotes the beginning of changed text within a section

🛑 Denotes the end of changed text within a section

____________________

18.1 Policy

All personnel who perform work on or near equipment in which the unexpected energization or start-up of the equipment, or the release of hazardous stored energy, could cause injury shall personally lock out the equipment for the duration of their work.

Persons performing work on projects or sites that do not fall under DOE jurisdiction are not required to follow the requirements of this LOTO Program. However, an equivalent LOTO program meeting applicable regulatory requirements will apply.

18.2 Scope

- Lockout/Tagout (LOTO) is required whenever construction, service, maintenance, modification, or demolition is being performed on or near equipment in which the unexpected energization or start-up of the equipment, or the release of hazardous stored energy, could cause injury to people.

- Hazardous energy is any form of energy that can cause personal injury, including but not limited to:

- Electrical

- Mechanical

- Rotational

- Gravitational

- Chemical

- Pressure or vacuum

- Hydraulic

- Pneumatic

- Non-ionizing radiation sources

- Thermal

18.3 Applicability

This program is required for all Berkeley Lab employees, affiliates, students, visitors, and subcontractors who may be exposed to hazardous energy while performing any construction, service, maintenance, modification, or demolition activity.

18.4 Exceptions

Lockout/Tagout (LOTO) is not required for each of the following situations:

- Normal operations, also known as normal production operations or normal energized operations, where the machine or equipment is utilized to perform its intended function and is covered by various chapters of the ES&H Manual

- Servicing or maintenance that take place during normal operations require LOTO only if:

- A person is required to remove or bypass a guard, cover, or other safety device or

- A person is required to place any part of his or her body into an area of a machine or piece of equipment where work is actually performed upon the material being processed (point of operation) or where an associated danger zone exists during a machine’s operating cycle

- Minor tool changes, adjustments, and other minor servicing activities that take place during normal operations do not require LOTO provided that:

- Such activities are routine, repetitive, and integral to the use of the equipment and

- The work is performed using alternative measures that provide effective personnel protection

- Servicing or maintenance that take place during normal operations require LOTO only if:

- Hot tap operations involving transmission and distribution systems for substances such as gas, steam, water or petroleum products when they are performed on pressurized pipelines, provided that it has been demonstrated that:

- Continuity of service is essential,

- Shutdown of the system is impractical, and

- Documented procedures are followed, and special equipment is used which will provide proven effective protection for employees.

- Energized testing and troubleshooting (e.g., alignment, measuring, calibration, fault finding) does not require LOTO where the equipment must be energized to perform the tests.

- Work on cord-and-plug-connected electrical equipment does not require LOTO controls when Work Process C is followed.

- Control of hazardous ionizing radiation is covered under Chapter 21 Radiation Protection Program. In radiation areas covered by credited control radiation, safety systems do not require LOTO controls when Work Process R is followed.

18.5 Roles and Responsibilities

|

Roles |

Responsibilities |

|

Division Electrical Safety Officer (DESO) |

|

|

Environment, Health and Safety (EHS) Division (Electrical Safety Group) |

|

|

Facilities Engineering |

|

|

Laboratory Electrical Safety Officer |

|

|

Limited LOTO Authorized Person |

|

|

Line management (including supervisors, managers, and work leads) |

|

|

LOTO Affected Person |

|

|

LOTO Approver |

|

|

LOTO Authorized Person |

|

|

LOTO Coordinator |

|

|

LOTO Person in Charge (LPIC) |

|

|

LOTO Procedure Evaluator |

|

|

LOTO Responsible Individual (RIs) |

|

|

LOTO Reviewer |

|

|

Qualified Person – Electrical (QEW) as well as Mechanical |

|

18.6 Definitions

|

Term |

Definition |

|

Absent Person lock removal |

A procedure for the removal of a lock and tag by someone other than the person who applied the lock and tag when that person is not present or available to remove the lock (Work Process O and Appendix C) |

|

Administrative Lock |

Any lock used for a purpose other than LOTO. The lock may serve a safety function other than LOTO, a configuration-control function, or other purpose. Can be any color except red. |

|

Blocked |

A condition where a mechanical device is inserted into the energy path to physically prevent movement. Most commonly used with moving parts. |

|

Capable of being locked out |

An energy isolation is capable of being locked out if it has a means of attachment to which, or through which, a lock can be affixed with the device in the “off” or de-energized position, or it has a locking mechanism built into it |

|

Complex LOTO |

Any LOTO that does not meet the requirements for a simple LOTO is called a complex LOTO. Requires an assigned LOTO Person In Charge and a LOTO procedure. |

|

Cord-and-plug- powered equipment |

Portable electric equipment, such as power tools, computers, printers, appliances, etc., for which exposure to the hazards of unexpected energization or start-up of the equipment is controlled by the unplugging of the equipment from the energy source and by the plug(s) being under the exclusive control of the employee performing the servicing or maintenance |

|

Credited control radiation safety system |

Specific definitions and requirements for radiation-generating devices, radiation safety systems and credited controls are found in the Chapter 21 Radiation Safety; Chapter 9 – Radiation Generating Device Program; and EHS Procedure 731, RGD Interlock Program. |

|

Division Electrical Safety Advocate (DESA) |

A non-qualified electrical worker assigned by the division to perform tasks to support the Electrical Safety Program within the division. |

|

Dissipated |

A condition where all stored energy has been reduced to a nonhazardous level. Pertains to energy-storing devices such as capacitors, pressure receivers, accumulators, reservoirs, or springs. |

|

Energized |

Connected to a hazardous energy source or containing residual or stored hazardous energy |

|

Energy isolation |

A mechanical device that physically prevents the transmission or release of energy, including but not limited to the following:

Energy isolations shall be capable of accepting an approved lockout device that physically prevents the actuation of the isolation. Push buttons, selector switches, software interlocks, and control circuit type devices are not energy isolations and cannot be used to isolate hazardous energy. Where the desired isolation consists of removing a spool piece, removing fuses, lifting electrical wires, or otherwise disconnecting an energy source without a lockable isolation, follow Work Process H, Tagout Only. |

|

Exclusive Control |

Under the exclusive control of the employee means that the LOTO Authorized Person is working alone and has the authority to, and is continuously in a position to, prevent (exclude) other individuals from re-energizing or starting the machine or equipment while performing the servicing or maintenance activity. |

|

Exposure |

The condition of being subjected to a source of risk presented by hazardous energy sources |

|

Group LOTO with a lockbox (Group Lockbox) |

A process to coordinate a complex LOTO so that LOTO Authorized Persons only have to apply a personal LOTO lock to a lockbox instead of at multiple energy isolation points. |

|

Group LOTO lock |

A LOTO lock used for the purpose of group LOTO. It is identified by a group LOTO lock tag. The keys to group LOTO locks are controlled in one or more LOTO lockboxes. |

|

Hazard zone |

The space near a source of hazardous energy where a person could be harmed if the hazardous energy was suddenly or unexpectedly released, such as the unexpected release of stored pressure, the unexpected movement of a machine, the unexpected energization of an electrical conductor, or the spray from a hazardous chemical that was unexpectedly released |

|

Hazardous energy |

Energy that is of such a magnitude that it is capable of causing harm to a person. Thresholds for hazardous electrical energy can be found in the LBNL Electrical Safety Manual. It is oftentimes necessary to involve technical experts to assist in the analysis of other forms of hazardous energy. |

|

Hazardous energy control |

The process of systematically implementing mechanical means to prevent hazardous energy from flowing to a person |

|

Hazardous Energy Control (HEC) Group |

A group consisting of Hazardous Energy Control Specialists, working for the Facilities Department, responsible for serving as the issuing authority for FAC LOTOs and Subcontractor LOTOs on FAC equipment. |

|

Hot Tap |

A procedure used in repair, maintenance and servicing activities, which involves welding on a piece of equipment (pipelines, vessels or tanks) under pressure, in order to install connections or appliances. It is commonly used to replace or add sections of pipeline without the interruption of service for air, gas, water, steam, and petrochemical distribution systems. |

|

Isolated |

A condition where a source of hazardous energy has been controlled by physically stopping the energy path so that the energy cannot flow to workers or equipment. The term “isolated” is commonly used with electrical circuits and fluid lines. |

|

Lockout/Tagout (LOTO) |

The method of applying a mechanical lockout device and a tag, or a special tagout-only tag managed in a lockbox, on an energy isolation by a LOTO Authorized Person in accordance with established procedures to control hazardous energies and prevent the equipment from being operated until the lockout device is removed |

|

Look-alike equipment |

Equipment that is similar in shape, size, and function that could lead a person to lock out Item A, but start working on Item B instead. Common examples are:

|

|

LOTO briefing sheet/LOTO log |

Used to document dates and times that LOTO briefings were performed or when LOTO Authorized Persons lock on and lock off. It’s also used to communicate to Limited LOTO Authorized Persons who they need to contact for a briefing before locking on. Link to suggested form can be found here. Divisions might have a different version identified in their LOTO Operating Program Document. |

|

LOTO device |

A device or combination of devices that, when applied to an energy isolation and fitted with a LOTO lock or a LOTO hasp:

|

|

LOTO lock |

A keyed red padlock used only for the purpose of LOTO |

|

LOTO lockbox |

A lockable box used to contain the key(s) of group LOTO locks, |

|

LOTO procedure |

A formal written document, approved by a LOTO Approver, that details the scope of work performed under the LOTO, the energy isolations to be established, and all steps required to execute the LOTO. |

|

LOTO program |

Per OSHA 1910.147, The employer shall establish a program consisting of energy control procedures, employee training and periodic inspections to ensure that before any employee performs any servicing or maintenance on a machine or equipment where the unexpected energizing, start up or release of stored energy could occur and cause injury, the machine or equipment shall be isolated from the energy source, and rendered inoperative. |

|

LOTO program assurance plan |

The purpose of this Lockout Tagout (LOTO) program assurance plan is to document assurance elements designed to review and monitor performance, understand how well the program is performing, and identify opportunities for improvement. (Work Process P.1) |

|

LOTO Responsible Individual (RI) lock |

A LOTO lock applied by the LOTO responsible individual (RI) for the purpose of controlling a complex or group LOTO. It is identified by an RI LOTO lock tag. The keys to LOTO RI locks are controlled by the RI. LOTO RI locks also function as personal LOTO locks for the RI. The following instances of complex LOTO require an RI Lock(s):

|

|

LOTO Safe Zone |

The portion of a system that has been placed in a safe work condition by executing the LOTO. |

|

LOTO tag |

A distinctive, durable tag approved by Berkeley Lab to identify a lockout device and the purpose of the lock. The LOTO tag is attached to the LOTO lock shackle. Different types of LOTO tags include:

|

|

Normal production operations |

The utilization of a machine or equipment to perform its intended production function |

|

Personal LOTO lock |

A LOTO lock issued to a LOTO Authorized Person for the purpose of individual control. No other person has the key or means of opening it. |

|

Physical separation |

Physical separation is the condition in which the sources of hazardous energy are physically removed from the work area to such an extent that Lockout/Tagout is not feasible and not necessary. See Work Process Q. |

|

Qualified Person |

A person who, by reason of experience and instruction, has demonstrated familiarity with the construction, installation, maintenance, and operation of the equipment, installations, and the hazards involved, has been designated by the supervisor or work lead to perform work on equipment. This employee also is required to be current with all required qualification training. |

|

Qualified Electrical Worker (QEW) |

A qualified person specifically authorized to work on electrical systems. For specific requirements, see Chapter 8 Electrical Safety. |

|

Safe Work Condition (Mode 0 for electrical work) |

A condition whereby the equipment has been placed in a zero-energy state and controlled to prevent re-energization through the process of lockout. Equipment is not safe to work on until it is in a safe work condition. |

|

Servicing and/or maintenance |

Workplace activities such as constructing, installing, setting up, adjusting, inspecting, modifying, maintaining, and/or servicing machines or equipment. These activities include lubricating, cleaning, or unjamming machines or equipment; and making adjustments or tool changes where the employee may be exposed to the unexpected energization or start-up of the equipment or release of hazardous energy. |

|

Setting up |

Any work performed to prepare a machine or equipment to perform its normal production operation |

|

Simple LOTO |

A process to establish a LOTO on equipment without a written LOTO procedure, provided that the conditions of Work Process D are met. |

|

Simple LOTO for Cord and Plug |

A process to establish a LOTO on equipment powered by a cord and plug, EHS0389, Simple LOTO for Cord-and-Plug Equipment. |

|

Stored energy source |

Any device capable of holding hazardous energy after equipment shutdown. This includes, but is not limited to, capacitors, coaxial cables, tanks, pipes, springs, and flywheels. |

|

Subcontractor LOTO Permit |

A LOTO procedure designed for subcontractors who will be |

|

Tagout only |

The placement of a LOTO tag directly on an energy isolation because the energy isolation cannot accommodate a LOTO lock. |

|

Trapped key interlock system |

An access control system where a key is held captive until a certain condition is satisfied. When the key is released, it may be used to unlock a new enclosure, lock out another device, or be placed in a Group Lockbox as part of a complex LOTO procedure. |

|

Zero Energy State |

A condition reached when all hazardous energy sources to or within equipment are isolated, dissipated with no possibility of re-accumulation, and verified as absent through proper testing. |

|

Zero Energy Verification (Mode 1 for electrical work) |

A process to verify a zero energy state. For electrical energy, this is called zero voltage verification (ZVV). |

18.7 Required Work Processes

Work Process A. LOTO Program Quick Reference Map

Work Process B. Basic LOTO Rules

Work Process C. Cord-and-Plug Equipment

Work Process D. Simple LOTO

Work Process E. Complex LOTO

Work Process F. Complex LOTO Requiring a Responsible Individual

Work Process G. Group LOTO With a Lockbox

Work Process H. Tagout Only

Work Process I. Subcontractor LOTO Permit

Work Process J. Shift Changes and Transfer of Control

Work Process K. Temporary Partial Restoration

🚩🚩Work Process K.1. Temporary Connections to Distribution or Premises Electrical Systems🛑

Work Process L. LOTO Hardware

Work Process M. Training and Authorization

Work Process N. Developing LOTO Procedures

Work Process O. Special Condition LOTO Lock Removal

Work Process P. Periodic Inspections of LOTO Procedures

Work Process P.1. LOTO Program Assurance Plan

Work Process Q. Physical Separation

Work Process R. Interlock Systems

Work Process S. Administrative Control

Work Process T. LOTO Coordination

Work Process A. LOTO Program Quick Reference Map

- The following is a reference guide to the rest of this document. Its intent is to guide the reader to the appropriate work processes with a brief overview. Detailed requirements are found in the referenced sections.

- An introduction to the core rules of LOTO is found in Work Process B, Basic LOTO Rules.

- Cord-and-plug equipment is exempt from LOTO and may be controlled by anyone who has received basic electrical safety training. See Work Process C, Cord-and-Plug Equipment.

- LOTO processes that can be performed directly by a LOTO Authorized Person are found in the following:

- Work Process D, Simple LOTO

- Work Process E, Complex LOTO

- LOTO processes of a complex nature that are managed by a designated RI:

- Work Process F, Complex LOTO Requiring a Responsible Individual

- Work Process G, Group LOTO With a Lockbox

- Work Process H, Tagout Only

- Work Process I, Subcontractor LOTO

- Work Process J, Shift Change & Transfer of Control

- Work Process K, Temporary Partial Restoration

- Additional programmatic requirements are found in the following sections:

- Work Process L, LOTO Hardware

- Work Process M, Training and Authorization

- Work Process N, Developing LOTO Procedures

- Work Process O, Special Condition LOTO Lock Removal

- Work Process P, Periodic Inspections of LOTO Procedures

- Work Process P.1. LOTO Program Assurance Plan

- The following work processes are commonly associated with energy control but are not integral to the LOTO process. They describe how to properly integrate these work practices with the LOTO Program.

- Work Process Q, Physical Separation

- Work Process R, Interlock Systems

- Work Process S, Administrative Control

- Work Process T, LOTO Coordination

- Additional Process Flows and Training Aids can be found here: https://electricalsafety.lbl.gov/loto/

Work Process B. Basic LOTO Rules

- Lockout/Tagout (LOTO) is the process of establishing a safe work condition on equipment prior to performing work. A safe work condition is established when the equipment has been placed in a verified zero-energy state and positively controlled to prevent unexpected re-energization.

- Lockout/Tagout (LOTO) is required whenever construction, service, maintenance, modification, or demolition is being performed on or near equipment in which the unexpected energization or start-up of the equipment, or the release of hazardous stored energy, could cause injury to people or damage to equipment. This includes access to areas where it would be unsafe unless the equipment were shut down and de-energized.

- All persons performing work on locked out equipment shall apply their personal LOTO lock(s) to that equipment. These persons shall be trained and authorized in accordance with Work Process M.

- LOTO Authorized Persons shall only apply or remove their own personal LOTO lock(s). No person shall ever remove another person’s personal LOTO lock, except under the restrictions of Work Process O, Special Condition LOTO Lock Removal.

- Note: The system operator control method found in OSHA 1910.269(d)(8)(v) is not applicable or permitted at Berkeley Lab.

- No person shall operate or attempt to operate any energy isolation to which a LOTO lock or tag is attached other than during the initial challenge when establishing the LOTO.

- For all LOTO devices, the LOTO Authorized Person applying the LOTO device must be knowledgeable about the proper use and application of the device. LOTO devices that are improperly affixed, or that are used on energy isolations for which they were not designed, may fail to prevent actuation of the isolation or fall off entirely. For this reason:

- Upon initially applying the LOTO device, the isolation is challenged to ensure that it will not operate.

- After this initial challenge, other persons MUST NOT challenge the LOTO device. This is to prevent the unintentional energization when the LOTO device is improperly applied.

- If any person should suspect that a LOTO device has been improperly applied, they must immediately contact the LOTO Person In Charge for resolution. If necessary, the LOTO Person In Charge must stop work and have everyone locked on remove their personal locks in order to correct the discrepancy.

- The LOTO Safe Zone is the extent of equipment that has been placed in a safe work condition. It is defined by the energy isolations that were selected for the LOTO.

- For work around electrical hazards, the shock thresholds listed as the Limited Approach Boundary in the LBNL Electrical Safety Manual shall be referenced. These shall be the trigger distance for implementing an Electrically Safe Work Condition (Mode 0 work). Each individual must apply their personal LOTO lock(s) prior to working within the Limited Approach Boundary.

- There are some exceptions for visual inspections that can be found in section 6.6.8 Visual Inspections of the Electrical Safety Manual.

- The LOTO Safe Zone must always encompass the entirety of the expected scope of work. If the scope of work is expected to shift outside of the LOTO Safe Zone, then the work must be stopped and the LOTO must be changed in order to accommodate the new scope of work.

- All lockouts shall be established following the requirements in this program. Push buttons, selector switches, software interlocks, and control circuits are not energy isolations and cannot be used to isolate hazardous energy.

- The LOTO Person In Charge of establishing a LOTO procedure must ensure that the LOTO Safe Zone matches the scope of work. Any LOTO Authorized Person locking onto the LOTO must understand the extent of the LOTO Safe Zone and remain vigilant that their scope of work does not extend beyond the LOTO Safe Zone.

- Only persons who are LOTO Authorized and Qualified may perform the necessary manipulation and testing required to establish the lockout. This includes equipment shutdown, operation of isolation devices, releasing stored energy, and verification of de-energization. When work is finished, this requirement also includes restoration, re-energization, and start-up of the equipment.

- Formal LOTO Briefings and the LOTO Briefing Sheet/LOTO Log:

- A formal LOTO briefing is the process of verbally communicating the detailed specifics of the LOTO to all LOTO participants. This includes the Qualified Persons supporting the LOTO and the LOTO Authorized Persons who will be adding their personal LOTO locks once the LOTO is established.

- The primary topics of these LOTO briefing are:

- Detailed description of the scope of work

- Detailed description of the LOTO Safe Zone

- Overview of expected conditions, or expected future modifications to the LOTO to support the work

- Discussion over what additional LOTO processes will be employed (such as transfer of control, temporary restoration for repositioning or testing, group lockbox, Tagout Only conditions, etc.)

- The LOTO briefing is a critical part of the LOTO process and required during certain LOTO situations for a LOTO Authorized Person and required at ALL times for the Limited LOTO Authorized Person prior to applying personal LOTO locks. See the LOTO Process Flow Job Aid for more details.

- There are two types of LOTO briefings:

- Before execution of the LOTO: This briefing is performed just before establishing the LOTO. This briefing is conducted by the LOTO Person in Charge and typically focuses on the scope of work and the LOTO safe zone being established.

- After the safe execution of the LOTO and the work zone is in a safe state: This briefing typically focuses on the type of work the employee will be performing in the LOTO Safe Zone and the boundaries of the LOTO Safe Zone.

- The LOTO briefing is repeated:

- Any time a Limited LOTO Authorized Person needs to apply their personal LOTO lock(s) to any established LOTO.

- Any time a LOTO Authorized Person needs to apply their personal LOTO lock(s) to a LOTO managed by a LOTO Responsible Individual (RI).

- When a LOTO is being turned over to be managed by a LOTO Responsible Individual (RI) or a new LOTO Person in Charge is being assigned.

- Before a shift change where a transfer of control needs to take place (Work Process J).

- Before and after temporary partial restoration (Work Process K).

- After a field change is performed (Work Process I).

- A documented LOTO Log must be signed:

- LOTO Person in Charge:

- When establishing a simple LOTO that involves Limited LOTO Authorized Persons.

- After establishing a complex LOTO with or without an RI.

- When being assigned as a new LOTO Person in Charge from another LPiC.

- Limited LOTO Authorized Persons:

- Before the application of LOTO locks and clearing of LOTO locks for Simple LOTO, Complex LOTO and Complex LOTO with an RI.

- LOTO Authorized Persons:

- Before the application of LOTO locks and clearing of LOTO locks for Complex LOTO and Complex LOTO with an RI.

- LOTO Person in Charge:

A LOTO Briefing Job Aid can be found with the LOTO Field Guides at: https://electricalsafety.lbl.gov/loto/.

Work Process C. Cord-and-Plug Equipment

- Cord-and-plug equipment refers to any electrical utilization equipment that uses a flexible cord and an attachment plug to connect to a source of hazardous energy.

- Persons working under the cord-and-plug exemption are not required to be LOTO Authorized Persons. However, persons that perform work on electrical equipment under the cord-and-plug exemption may need to be Qualified Electrical Workers. See the Chapter 8 Electrical Safety program for more information.

- Note that hard-wired electrical utilization equipment shall not be converted to cord-and-plug connection unless it meets the requirements and intent of NFPA 70 – National Electrical Code (NEC) Sections Article 400.7 and 400.8 and NRTL and manufacturer instructions.

- Cord-and-plug equipment is exempt from LOTO controls when:

- All hazardous energy is controlled by unplugging the equipment, and

- The plug(s) remain(s) under the exclusive control of the worker performing the work. Under the exclusive control of the worker means that the authorized person has the authority to, and is continuously in a position to, prevent (exclude) other individuals from re-energizing or starting the machine or equipment while performing the servicing or maintenance activity.

- Note: Two or more people cannot simultaneously have exclusive control over the same set of plugs, so this effectively means that exclusive control is only possible when a person is working alone.

- For cord-and-plug equipment that does not meet the exemption requirements, the LOTO process shall be applied.

- If there is stored energy above hazardous thresholds listed in Table 2.2.13 of the LBNL Electrical Safety Manual, such as capacitors 100 V or greater and 10 Joules or greater, a Complex LOTO Procedure must be used.

- If exclusive control cannot be established and there is a single plug and no hazardous stored energy, Simple LOTO for Cord and Plug may be used. If, however, there are multiple cords, a Complex LOTO Procedure must be used.

- For equipment with a removable cable, it is suggested that you use a detachable cord plug lockout device like the one pictured below:

- Examples that meet the requirements for the cord-and-plug exemption:

- A benchtop instrument with a 120 VAC, 15 Amp cord. It has no stored energy, and unplugging the cord completely removes all hazardous energy from the device.

- A welder with a 480 VAC, 100 Amp cord. It has no stored energy, and unplugging the cord completely removes all hazardous energy from the device.

- A bandsaw with a 120 VAC, 15 Amp cord. It has no stored energy, and unplugging the cord completely removes all hazardous energy from the device.

- A vacuum chamber where exclusive control can be established for all cables connected to it, and there is no possibility of coming into contact with any hazardous stored energy.

- Examples that do not meet the requirements for the cord-and-plug exemption:

- Rack-mounted instrument with a 120 VAC, 15 Amp cord. The cord plugs into a power strip located in the back of the unit and is not accessible from the front. The worker needs to perform a task on the front of the panel and cannot see or control where the plug is located. A simple LOTO is required because exclusive control cannot be established.

- A benchtop laser with 120 VAC, 15 Amp cord and an internal capacitor bank with 25 J of stored energy. A complex LOTO procedure is required because of the hazardous stored energy.

- Equipment that has multiple cords where exclusive control cannot be maintained. In this case, LOTO would be considered complex and require a LOTO procedure.

- Two or more people are working simultaneously on the equipment.

Work Process D. Simple LOTO

- The simple LOTO process is a LOTO that does not require an approved, written LOTO procedure. This process may be used by a LOTO Authorized Person to establish a safe work condition prior to performing work. The LOTO Authorized Person is responsible for determining whether the conditions for the simple LOTO process are satisfied. If these conditions are not satisfied, then the LOTO Authorized Person shall follow the complex LOTO process. Subcontractor QEWs may be approved to perform Simple LOTO on hard-wired equipment without a Subcontractor LOTO Permit. See Work Process I.

- Conditions: The simple LOTO process is allowed only if all of the following conditions are met:

- The machine or equipment has no potential for hazardous stored or residual energy or reaccumulation of hazardous stored energy after shut down which could endanger employees.

- The machine or equipment has a single energy source which can be readily identified and isolated.

- The isolation and locking out of that energy source will completely deenergize and deactivate the machine or equipment.

- The machine or equipment is isolated from that energy source and locked out during servicing or maintenance.

- The lockout device is under the exclusive control of the authorized employee performing the servicing or maintenance.

- The servicing or maintenance does not create hazards for other employees.

- There have been no known accidents involving the unexpected activation or re-energization of the machine or equipment during servicing or maintenance.

- 🚩Temporary connections to distribution or premises electrical systems shall not be performed under simple LOTO. Approved FLP or LP required prior to work start. Temporary power systems must be approved by IAHJ prior to installation.🛑

- For major process/equipment overhaul, rebuilds, etc., which do not require any Subcontractors, but consist of multiple crews, crafts or departments made up of LBNL LOTO Authorized Persons all performing LOTO under the Simple LOTO criteria, a decision may be made by the LOTO Authorized Person or Division ESO to require a complex LOTO Procedure.

- In order to execute the simple LOTO process, the LOTO Authorized Person shall also be a Qualified Person on the system.

- Additional LOTO Authorized Persons can add their lock to the isolation.

- If Limited LOTO Authorized Persons are participating, a LOTO Person in Charge must be assigned, a briefing sheet will be required and must be signed after receiving the required LOTO briefing from the LOTO Person in Charge.

- Only LBNL Qualified Electrical Workers, as designated in the Chapter 8 Electrical Safety Program, may perform work on electrical circuits that operate at voltages greater than the hazardous thresholds outlined in Chapter 8; Table D-1. This includes establishing LOTO on equipment where zero voltage verification needs to be performed.

- For other forms of hazardous energy, this qualification depends on line-management authorization.

- Establish the LOTO.

- Step 1 — Identify energy source and related hazards/controls.

- Assess the type, magnitude, and hazards of the energy to be controlled. If there is more than one energy source, or if there is a source of hazardous stored energy, then the simple LOTO method may not be used. Follow the complex LOTO method instead.

- Determine the appropriate method for controlling the source of hazardous energy. Methods for energy isolation may include such things as circuit breakers, disconnect switches, or valves. Remember that control circuits such as push buttons, selector switches, emergency stops, contactors, and remotely operated valves are not energy isolations.

- Determine the appropriate safe work practices for performing the isolation and verification of zero-energy state. Only a Qualified Person wearing proper PPE may operate the isolation and perform verification of zero-energy state.

- Step 2 — Notify affected persons.

- Notify all Affected Persons of the impending shutdown and lockout. These persons must be informed that they are not to disturb the lockout device or attempt to restart the equipment until they are informed that the lockout has been cleared and it is safe to resume normal operations.

- Step 3 — Shut down equipment.

- Verify that it is safe to shut down equipment, then perform normal equipment shutdown. Turn off or shut down the equipment using the established method for that equipment.

- Step 4 — Isolate energy source.

- Identify the correct energy-isolation device before operation. Take steps to ensure that the means used (disconnect, valve, etc.) for energy isolation correctly corresponds to the equipment on which LOTO is being performed. Check the isolation label and match it to the label on the equipment. Take special care with look-alike equipment.

- Isolate the energy source by operating the energy isolation (switch off, valve off, etc.).

- Step 5 — Apply LOTO lock and tag.

- Equipment design may require performing the verification in Step 6 prior to the application of lock and tag.

- Apply the required LOTO device to the energy isolation in such a way that it physically prohibits operation of the energy isolation. Always allow for the possibility that another person may need to join the LOTO; use a LOTO hasp if necessary to leave space for additional persons to lock on. Apply the personal LOTO lock and tag to the LOTO isolation, LOTO device, or LOTO hasp as appropriate. Write name, phone number, and any other relevant information on the LOTO tag.

- Step 6 — Verify proper isolation.

- Challenge the LOTO:

- DO NOT ATTEMPT TO OPERATE THE ENERGY ISOLATION IF ANY OTHER LOTO LOCK IS ALREADY APPLIED. DOING SO COULD RESULT IN INADVERTENT ENERGIZATION OF THE SYSTEM AND EXPOSE PERSONNEL TO HAZARDOUS ENERGY.

- EVERY TIME: Challenge your personal LOTO lock to ensure that the lock is fully latched.

- ONLY IF YOU ARE APPLYING THE FIRST LOTO LOCK: Challenge the LOTO device to ensure that it cannot be removed from the isolation.

- ONLY IF YOU ARE APPLYING THE FIRST LOTO LOCK: Challenge the energy isolation to ensure it will not operate.

- Attempt to start equipment:

- Attempt to restart the equipment using the normal equipment controls.

- Verify the equipment will not power up or start.

- Verify zero energy:

- Test the energy source using appropriately rated instruments.

- Any instrument used to test for voltage, pressure, or temperature shall be checked for proper operation both before and after use on a known live source.

- The test point must be directly connected to the energy isolation. There cannot be other system components (such as check valves, contactors, other in-line switches or fuses) between the test point and the isolation, as these may mask the presence of energy on a deficient isolation.

- All energy is to be treated as present until positively proven otherwise. This means that applicable safe work practices and required PPE shall be used to perform the test for zero-energy state.

- Challenge the LOTO:

- Step 1 — Identify energy source and related hazards/controls.

- Perform the Work

- The lockout shall remain in place for the duration of work.

- Other LOTO Authorized Persons may join the LOTO by applying their personal LOTO lock and tag

- Limited LOTO Authorized Persons will require a LOTO briefing and will need to sign the briefing sheet to acknowledge having received the briefing.

- Everyone locked on must remain vigilant and ensure that the scope of work does not extend out of the LOTO Safe Zone. If the persons performing work identify a task that falls out of the LOTO Safe Zone, then work will be stopped and a decision will be made either to modify the LOTO or to forgo the work until the LOTO can be modified.

- Release from LOTO

- Step 1 — Confirm It Is Safe to Re-energize

- Confirm that the work for which the LOTO was applied has been completed and that it is safe to re-energize equipment. Clear all tools and personnel. Check the work area to ensure that all tools, debris, and personnel are at a safe distance from the equipment. Replace safety guards. Check the equipment to ensure that any removed guards are reinstalled.

- Confirm that all safety inspections have been performed.

- Confirm that all employees are in a safe position. Ensure all persons remain clear of the equipment’s point of operation or hazard zone.

- Step 2 — Remove LOTO Locks and Tags

- Remove all personal LOTO lock(s) and tag(s) from the isolation. Each personal LOTO lock shall only be removed by the LOTO Authorized Person who applied it.

- Exception: If the person who placed the lock and tag is not available, the procedure for Absent Person removal of LOTO devices shall be followed (Work Process O).

- Step 3 — Notify all Affected Persons that the LOTO has been released and equipment will be re-energized.

- Step 4 — Re-energize and restore the equipment to the normal condition.

- Step 1 — Confirm It Is Safe to Re-energize

- Simple LOTO Continuing for More Than One Work Period

- Equipment that will be placed out-of-service for an extended period of time may be controlled using an administrative lock (Work Process S) instead of a LOTO lock when no work is being performed.

- Alternatively, a Simple LOTO may remain in place while work is not being performed when the equipment is not safe to be reenergized.

Work Process E. Complex LOTO

- The complex LOTO process is triggered anytime the conditions for the simple LOTO (Work Process D) cannot be met. It requires an approved written LOTO procedure,

or a Subcontractor LOTO Permit if a Subcontractor will be participating in the LOTO, and a designated LOTO Person In Charge who is accountable for the safe execution of the LOTO.

- For complex LOTOs involving group LOTO with a Lockbox, Tagout Only, multiple employers,

🚩temporary connection to distribution or premises electrical system, 🛑temporary partial restoration, or shift changes that require a transfer of ownership, Work Process F, Complex LOTO Requiring a Responsible Individual, must be followed.

- Every complex LOTO shall have an approved written LOTO procedure that meets the requirements of Work Process N.

- The LOTO procedure is a formal written document, approved by a LOTO Approver, which details the scope of work performed under the LOTO and the energy isolations to be established.

- The LOTO procedure also details, where required, the method of hazardous stored energy dissipation and any specific sequence required for the shutdown.

- The LOTO procedure must be documented each time it is performed. There are two ways of documenting, routine and non-routine:

- For non-routine LOTO procedures, procedures should be printed out and posted at the jobsite or otherwise made available for LOTO Authorized Persons to reference.

- Routine LOTO procedures are equipment specific LOTO procedures that are performed over and over without change. When used, it’s strongly suggested that routine LOTO procedures be posted at the equipment. The purpose of posting a routine LOTO procedure is so that it does not have to be reprinted for each use. Check to make sure the scope of work matches the procedure and then complete the LOTO log associated with that procedure.

- These documents should be kept within your division for auditing purposes.

- In order to execute a complex LOTO, the LOTO Authorized Person should also be a properly Qualified Person on the equipment. If a LOTO Authorized Person requires a complex LOTO but is not a Qualified Person on the system, the LOTO Authorized Person must request assistance from a properly LOTO Authorized and Qualified Person.

This person will be the LOTO Person in Charge.

- If the initial LOTO Person in Charge establishing the LOTO will not be staying the duration of the LOTO, they must transfer their LOTO Person in Charge role to another equally trained and Qualified Person (Work Process B.11). After the new LOTO Person in Charge fully understands the LOTO safe zone that has been set, then they shall apply their personal LOTO locks to all isolations and the outgoing LOTO Person in Charge can remove their LOTO locks. This transfer shall be documented on a LOTO Briefing Sheet/LOTO Log.

- Only LBNL Qualified Electrical Workers, as designated in the Chapter 8 Electrical Safety Program, may perform work on electrical circuits that operate at voltages greater than the hazardous thresholds outlined in Table D-1. This includes establishing LOTO on equipment where zero voltage verification needs to be performed.

- For other forms of hazardous energy, this qualification depends on line-management authorization.

- Establishing the Complex LOTO

- Step 1 — Preparation

- Determine whether you are a Qualified Person who has been trained to operate the isolations and perform zero-energy verifications described in the LOTO procedure. If not, contact a Qualified Person and have him or her assist you in executing the LOTO procedure.

- Print out and review the LOTO procedure. Verify that the scope of work to be performed is described in the LOTO procedure, and that the LOTO Safe Zone is adequate for all planned work.

- If the LOTO procedure requires revision or is otherwise inadequate, STOP WORK and contact the equipment owner to obtain the proper LOTO procedure.

- Perform a job briefing as outlined in Work Process B.11 (even if you’re working alone).

- Do you understand the scope of work

- Do you have the appropriate LOTO equipment required to lockout the isolations; LOTO locks, tags, isolation devices?

- Step 2 — Notification

- Notify all Affected Persons of the impending shutdown and lockout. Affected Persons must be informed that they are not to disturb the lockout devices or attempt to start up the equipment until they are informed that the LOTO has been cleared and it is safe to resume normal operations.

- Step 3 — Follow the LOTO Procedure

- Shut down the equipment. Some LOTO procedures will have a required sequence to properly shut down the equipment. This will be attached to the isolation checklist and must be followed exactly as described.

- For each isolation listed on the LOTO procedure, the simple LOTO steps from Work Process D are followed, including:

- Shutdown

- Isolation

- Application of locks and tags to all isolations listed on the procedure

- Verification: Challenge/Attempt to Start/Zero Energy

- Using the isolation checklist, verify that all isolations have been locked out and that absence of energy has been positively verified. It is not acceptable to only lockout some of the isolations listed on the LOTO procedure.

- Some isolations may also require stored energy dissipation. The exact method of dissipation will be described in the LOTO procedure.

- Sign off on the LOTO Briefing Sheet/LOTO Log to indicate that the LOTO procedure has been established.

- Post the completed LOTO procedure next to the work area.

- Step 1 — Preparation

- Performing Work under a Complex LOTO

- The lockout shall remain in place until work on the equipment is complete.

- Other LOTO Authorized Persons may join the LOTO:

- LOTO Authorized Persons shall review the LOTO procedure and verify the scope of work and isolations creating the LOTO safe zone match the scope of work that will be performed. They shall then apply their personal LOTO locks and tags to each of the energy isolations listed in the LOTO procedure and then sign the

LOTO Briefing Sheet/LOTO Log

.

- Limited LOTO Authorized Persons will need to contact the LOTO Person in Charge listed on the LOTO Briefing Sheet for the job and get a briefing before applying their personal locks.

- LOTO Authorized Persons shall review the LOTO procedure and verify the scope of work and isolations creating the LOTO safe zone match the scope of work that will be performed. They shall then apply their personal LOTO locks and tags to each of the energy isolations listed in the LOTO procedure and then sign the

- Everyone locked on must remain vigilant and ensure that the scope of work does not extend beyond the LOTO Safe Zone. If the persons performing work identify a task that falls out of the LOTO Safe Zone, then work will be stopped and a decision will be made either to submit a new LOTO procedure for approval or to forgo the work until the LOTO can be modified.

- If it is necessary to temporarily remove only one or some LOTO devices before work is complete, such as for testing or repositioning equipment, a Responsible Individual must be assigned according to Work Process F before following Work Process K, Temporary Partial Restoration.

- Releasing the Complex LOTO

- Step 1 — Confirm That It Is Safe to Re-energize.

- Confirm that the work for which the LOTO was applied has been completed and that it is safe to re-energize equipment. Clear all tools and personnel. Check the work area to ensure that all tools, debris, and personnel are at a safe distance from the equipment. Replace safety guards. Check the equipment to ensure that any removed guards are reinstalled.

- Confirm that all safety inspections have been performed and all return to service steps have been completed per the requirements listed in the LOTO procedure.

- Confirm that all employees are in a safe position. Ensure all persons remain clear of the equipment’s point of operation or hazard zone.

- Step 2 — Removal of Locks and Tags

- Remove LOTO lock(s) and tag(s) and sign the LOTO Briefing Sheet/LOTO Log. Personal LOTO locks shall only be removed by the LOTO Authorized Person who applied it.

- Exception: If the person who placed the lock and tag is not available, the procedure for Absent Person removal of LOTO devices shall be followed (Work Process O).

- Remove LOTO lock(s) and tag(s) and sign the LOTO Briefing Sheet/LOTO Log. Personal LOTO locks shall only be removed by the LOTO Authorized Person who applied it.

- Step 3 — Notify all affected persons that the LOTO has been released and equipment will be re-energized.

- Step 4 — Re-energize and restore the equipment to the normal condition.

- Step 5 — Sign off the LOTO Briefing Sheet/LOTO Log to indicate that the complex LOTO has been cleared. Follow the archive process set up within the division.

- Step 1 — Confirm That It Is Safe to Re-energize.

Work Process F. Complex LOTO Requiring a Responsible Individual

- The Responsible Individual (RI) is a LOTO Authorized Person who has been trained to properly manage work activities under the LOTO procedures of a more complex nature than those allowed under Work Process E.

- The following instances of complex LOTO require a Responsible Individual:

- Group LOTO With a Lockbox (Work Process G)

- Tagout Only (Work Process H)

- Multiple employers (Work Process I)

- Shift changes that require a transfer of ownership between shifts (Work Process J)

- Temporary partial restoration (Work Process K)

- Temporary connection to distribution or premises electrical system for temporary power distribution (Work Process K.1.)🛑

- Designating an RI for a particular LOTO procedure triggers the following additional requirements:

- RI LOTO locks and tags

- Formal LOTO briefing including all LOTO Authorized Persons (Work Process B.11)

- RI LOTO Locks

- An RI LOTO lock is a LOTO lock applied by the RI of a particular lockout. It is identified by the RI LOTO tag attached to the LOTO lock. The RI LOTO locks enable the RI to maintain positive control of the isolations.

- An RI LOTO lock applied to an energy isolation indicates that:

- This particular isolation was performed for the purpose of LOTO

- All verification steps were completed satisfactorily and witnessed by the RI

- This particular isolation has been maintained under continuous positive control by the RI since performing the verification steps

- RI LOTO locks allow the RI to witness the verification of zero-energy state without passing on that requirement to subcontractors.

- RI LOTO locks also function as personal LOTO locks for the RI.

- The Responsible Individual must identify conditions where additional measures may be required to ensure the safety of all persons involved in the LOTO. These conditions include situations where the LOTO Safe Zone is difficult to readily identify, or where multiple changes in scope result in transitions from one LOTO permit to the next. It is up to the RI to call upon the help of their DESO or the HEC Group for additional assistance. Additional measures may include added supervision, special temporary marking of equipment, or additional LOTO briefings.

- Steps for implementing the Complex LOTO by a Responsible Individual shall follow the steps listed in Work Process E (these might be different within your Division, so check with your DESO/DESA to make sure your Division does not have an internal LOTO Program). LOTO with an RI differs from complex LOTO without an RI for the following reasons: Steps for implementing the Complex LOTO by a Responsible Individual shall follow the steps listed in Work Process E (these might be different within your Division, so check with your DESO/DESA to make sure your Division does not have an internal LOTO Program).

LOTO with an RI differs from complex LOTO without an RI for the following reasons:

- For each isolation, the Responsible Individual must secure each isolation with the appropriate lock and tag. First lock on and the last lock off.

- If the RI is not the Qualified Person establishing LOTO, they must witness the establishment of LOTO to ALL isolations, including the zero energy verification.

- The Responsible Individual must brief all the LOTO Authorized Persons and Limited LOTO Authorized Persons before they apply personal locks to the isolations or lockbox(es).

- The Responsible Individual can remove the RI lock from the isolations or lockbox(es) and the equipment can be returned to service by the equipment owner once the following has occurred:

- All the work has been completed.

- All safety inspections have been performed and all return to service steps have been completed.

- After each LOTO Authorized Person has removed his/her respective personal LOTO locks from the isolations or lockbox(es) and signs the LOTO Briefing Sheet/LOTO Log.

Work Process G. Group LOTO With a Lockbox

- A group LOTO is a process used to perform a complex LOTO with a lockbox. Instead of applying personal LOTO locks to each energy isolation, the energy isolations are locked out with group LOTO locks. The keys to the group LOTO locks are placed in the lockbox, which is then locked by the Responsible Individual (RI) and each LOTO Authorized Person.

- The RI may elect to use the Group LOTO process at any time to better facilitate the coordination of a LOTO. Group LOTO is required when performing Tagout Only (Work Process H). Otherwise, group LOTO is not required but may present a desirable solution to effectively manage a large number of persons or isolations.

- Group LOTO Locks

- A group LOTO lock is a LOTO lock used specifically for group LOTO. It is identified by the group LOTO tag attached to the LOTO lock.

- A group LOTO lock is applied by the RI to each energy isolation during the execution of a group LOTO procedure. The keys to the group LOTO locks are then placed in a lockbox, which is then locked with an RI lock. Group LOTO locks are mandatory for the group LOTO method.

- A group LOTO lock applied to either an energy isolation device or to another lockbox indicates that:

- A particular isolation was

locked out for the purpose of group LOTO

- All verification steps were completed satisfactorily and witnessed by the RI

- This particular energy isolation has been maintained under continuous positive control by the RI since performing the verification steps

- A particular isolation was

- Steps to Implement a Group LOTO With a Lockbox

- The RI determines that the group LOTO work process is appropriate.

- The RI manages the execution of the written LOTO procedure as described in Work Process F.

- Instead of RI Locks, the RI must apply group LOTO locks to the energy isolations or to hasps attached to those isolations.

- The RI shall place the group LOTO lock keys inside a lockbox.

- The RI must lock the lockbox closed with an RI lock and tag on the outside of the lockbox.

- The RI must attach the completed LOTO procedure to the lockbox.

Each lockbox will be clearly identified with the associated LOTO Permit or Procedure number. Each lockbox will be clearly identified with the associated LOTO Permit or Procedure number.

- The RI must brief all LOTO Authorized Persons before they apply personal locks to the lockbox (or any isolation if conditions in 5.b below is requested).

- All other workers performing work on the equipment satisfy themselves that the group LOTO procedure has been completed, and then apply their personal LOTO lock and tag to the lockbox in a manner that prevents access to the enclosed key(s) until all locks have been removed from the box.

- When the work has been completed, and after each worker has removed his/her respective personal LOTO lock from the lockbox and signed off on the LOTO Briefing Sheet/LOTO Log, the RI removes their RI lock from the outside of the lockbox, obtains the group LOTO lock keys from the lockbox, removes the group LOTO locks, and the equipment can be returned to service by the equipment owner.

- There are times where the RI must take additional measures to accommodate a LOTO Authorized Person who has concerns about a group LOTO or who is not fully satisfied with the group LOTO method. The RI shall make necessary arrangements to accommodate such requests.

- Any LOTO Authorized Person may request to either witness the verification or reverification of zero-energy state on some or all of the energy isolations. In this case, the RI must coordinate with a Qualified Person to perform the requested verifications.

- Any LOTO Authorized Person may request to not participate in the group LOTO and instead apply personal LOTO locks directly to the isolations, next to the group LOTO locks. The LOTO must then be treated as a complex LOTO under Work Process F. Under the direction of the RI, who must be physically present, the LOTO Authorized Person must apply their personal LOTO locks to each energy isolation listed on the LOTO procedure without exception.

- Location

- Once established, the LOTO lockbox must be kept in a location that is accessible to the LOTO Authorized Persons participating in the group LOTO.

- Pyramiding

- One or more lockboxes can be referenced under a master complex LOTO procedure or another group LOTO procedure. This is useful when managing lockouts with extensive scope and complexity.

- There must be only one group LOTO procedure per lockbox. If it is necessary to group multiple LOTO procedures under one master lockbox, each procedure must first be built into its own separate group LOTO. When pyramiding lockboxes, each lockbox must have its own LOTO procedure attached to the lockbox. The master lockbox LOTO procedure must reference each subordinate lockbox on the master lockbox permit.

Work Process H. Tagout Only

- “Tagout only” is the practice of applying a LOTO tag without a LOTO lock, where the physical construction of the energy isolation does not accommodate the attachment of a lock.

- Extra caution shall be exercised when using a Tagout Only procedure. Tags may evoke a false sense of security. Tags are warning devices and do not provide the physical restraint provided by a lock.

- Criteria:

- In the rare case that a device is not capable of being locked out, this Work Process H may be used, subject to the following conditions:

- A justifiable and verifiable need must be identified.

- Formal approval must be obtained from the immediate supervisor or other line management.

- Any energy isolation capable of being locked shall be locked WITHOUT EXCEPTION.

- In the rare case that a device is not capable of being locked out, this Work Process H may be used, subject to the following conditions:

- Examples of Tagout Only situations include:

- Circuit breakers actuated by handles mounted on the exterior of a panel door

- When work is required inside the enclosure, opening the enclosure disconnects the actuating handle from the breaker. This defeats the application of a LOTO lock on the handle, and there is usually no physical means to apply a lock inside the enclosure, directly to the breaker.

- In this case, a tagout must be applied to the breaker inside the enclosure. Additional measures can include removing the actuator-connecting bar or also tagging out the handle on the door. The concern is that, should the door be closed, the handle could be operated, closing the breaker.

- Street valves located in deep holes with no possible means of attaching a lockout device

- Circuit breakers actuated by handles mounted on the exterior of a panel door

Tag-out only used because the manhole cover cannot be locked to the street.

c. Fuse removal

d. Blanking, blocking, blind flanging, or capping a pipe system

- Performing a Tagout Only procedure requires a secondary measure. At Berkeley Lab, the secondary measure consists of using a serialized LOTO tag. The Tag-out only LOTO tag must have the same serial number printed on its top and bottom portions, which are separated by a perforation in the tag to make it easy to remove the bottom portion (the “stub”). The RI attaches the top portion to the isolation and detaches the tag’s bottom stub. The stub goes into a lockbox where it performs a function analogous to the Group LOTO key in a Group LOTO. All other participants in the LOTO lock onto the lockbox.

- Procedure

- Tagout must only be conducted under group LOTO With a Lockbox (Work Process G).

- To tag out an isolation, the Responsible Individual must follow all the steps outlined in the group LOTO Work Process G, with the following changes:

- The written LOTO procedure line item for the isolation to be tagged out must indicate:

- That the isolation is “TAGOUT ONLY”

- The serial number of the group LOTO tag (May be handwritten)

- Directly affix to the isolating device a serialized tagout tag with a detachable stub instead of a group LOTO lock and tag.

- The tag attachment means shall be capable of withstanding at least 50 pounds of force exerted at a right angle to the disconnecting means’ surface.

- The tag attachment means shall be non-reusable, attachable by hand, self-locking, and non-releasable, equal to an all-environment-tolerant nylon cable tie.

- Tear off the tagout tag stub and place it in the lockbox. Write the tag serial number onto the group LOTO procedure.

- Complete the group LOTO procedure. Once the procedure is completed, the RI locks the box with the RI lock. All persons performing work under the tagout will then apply their personal LOTO locks to the lockbox.

- When it’s time to release the LOTO, all participants unlock from the lockbox so the RI can retrieve the Tag-Out only tag stub. The RI must then verify that the serial number on the stub matches the serial number on the top portion of the tag on the isolation before releasing the isolation. If the serial numbers do not match, the isolation must not be released.

- The written LOTO procedure line item for the isolation to be tagged out must indicate:

Work Process I. Subcontractor LOTO Permit

- The subcontractor LOTO permit is a Complex LOTO procedure designed for subcontractors who will be performing simple as well as complex LOTO. It incorporates the standard Berkeley Lab LOTO procedure format with a process to verify that subcontractors have received the appropriate training and supervision prior to participating in a LOTO.

- All subcontractors performing work for Berkeley Lab are required to conform to the Berkeley Lab LOTO Program. This Work Process I contains additional requirements to ensure that subcontractors are adequately managed and protected from hazardous energy exposures. The subcontractor LOTO permit process is in place to implement these requirements.

- Subcontractors include all construction and non-construction subcontractors, all vendors, and all manufacturer representatives or other persons performing or participating in LOTO who are not covered under the Berkeley Lab employee Chapter 6 Work Planning and Control and are therefore not subject to employee LOTO training and authorization requirements.

- All subcontractor LOTO permits require a designated LOTO Responsible Individual (RI) and are implemented by following Work Process F, Complex LOTO Requiring a Responsible Individual. The Subcontractor LOTO permit may waive the requirement for RI locks on a case-by-case basis.

- The LOTO RI, or designee, submits Subcontractor LOTO permit requests to the LOTO Permit Database. The requests are reviewed and approved by the designated LOTO Approver who is responsible for the area involved. Prior to participating in any LOTO, subcontractors must have an approved and printed subcontractor LOTO permit and must be briefed by the designated LOTO RI.

- Subcontractors/vendors are expected to provide their own LOTO equipment. Berkeley Lab may loan LOTO hardware as needed to meet urgent operational necessities. All subcontractor LOTO hardware must meet the requirements set in Work Process L.

- Only Subcontractor Qualified Electrical Workers (QEWs) who have been separately and individually approved under the Electrical Safety Program may perform their own zero voltage verification (ZVV) on electrical lockouts. See the Chapter 8 Electrical Safety program for more information.

- Subcontractor QEWs may be approved to perform Simple LOTO on hard-wired equipment without a Subcontractor LOTO Permit provided that:

- All conditions for Simple LOTO in Work Process D are met.

- They complete EHS0370, Lockout/Tagout for Authorized Persons

- The equipment is labeled with an up-to-date arc flash label.

- Approval is obtained from the Laboratory Electrical Safety Officer. Note: Approval is normally restricted to new building construction projects and is specified in the project’s Electrical Energization Plan.

- Cord-and-plug equipment:

- Cord-and-plug equipment is exempt from LOTO provided it meets the requirements of Work Process C.

- Where exclusive control of a single plug cannot be achieved and there is no hazardous stored energy, a Simple LOTO may be used without a Responsible Individual (RI) or Subcontractor LOTO Permit, but the Subcontractor employee will need to complete the course EHS0379, Subcontractor Lockout/Tagout online and add their personal lock and tag to the LOTO device.

- If 9.a or 9.b do not apply, then a Subcontractor LOTO Permit must be obtained. This Subcontractor LOTO Permit can act as your LOTO procedure for the equipment.

- RI Responsibilities for the LOTO Permit

- The RI must ensure that all requirements of Work Process F are followed when implementing the LOTO permit.

- In addition, the Responsible Individual must in the course of the LOTO briefing ensure that all subcontractors participating in the LOTO fully understand their responsibilities. Special emphasis must be placed on the following:

- Clearly defining the scope of work allowed under the LOTO permit

- Clearly defining the extent of the LOTO Safe Zone

- Specifying that any participant who needs to deviate from the original planned scope of work must consult with the RI BEFORE proceeding with any such work.

- Specifying that all personnel participating in the LOTO must be personally locked out with a red LOTO lock and tag for the duration of their work

- Specifying that no new person can participate in the LOTO without first contacting the Responsible Individual and obtaining a LOTO briefing

- Upon completion of the LOTO, the Responsible Individual

shall follow the archive process set up within the division.

- LOTO Permit Expiration Dates

- Construction LOTO Permits:

- There are times where a permit might need to be implemented several times over the course of a project.

- LOTO Permits in the database expire 60 days from the date of approval and the “Print” button will disappear. The RI will need to get an extension from a DESO, HEC Group, or the Electrical Safety Group to extend the length of that permit and be able to print it again.

- Permits hanging in the field DO NOT EXPIRE as long as they have not been released from LOTO.

- Non-Construction LOTO Permits:

- These permits are often issued for programmatic equipment and conditions often do not change after initial review.

- These permits do not expire in the database as long as the following stays the same:

- There is no change in the initial isolation point(s).

- The scope of work and company performing the zero energy verification remains the same.

- The Subcontractor has taken EHS0379 within the past three years.

- Construction LOTO Permits:

- EHS Division Responsibilities

- Review Subcontractor LOTO Permits as part of the audit process outlined in the EHS Assurance Program.

- Maintain the Quickbase Database used for the Subcontractor LOTO Permit process.

- Field changes

- A field change is a pen and ink markup of a LOTO Permit that corrects an error discovered during the execution of the LOTO. Field changes to LOTO Permits may be allowed with certain restrictions.

- Only certain types of field changes are allowed:

- Improper Labeling: A difference in information on permit vs. panel

- Change in Scope of Work: Scope change after permit approval. This is only allowed when the new scope of work is determined to be clearly within the LOTO safe zone.

- Additional Energy Source Discovered: Energy source discovered during zero energy verification

- Isolation Not Required

- Other: Small change to information in area affected or special instructions

- A field change record sheet must be completed for any field change. Authorization must be obtained verbally from a DESO, HEC Group, or the Electrical Safety Group and can be done over the phone.

- A field change will not be approved in the following conditions. Contact a LOTO Coordinator for assistance with modifying the permit instead:

- If there is time to modify the electronic version of the permit instead.

- If the change represents a significant departure from the original LOTO Safe Zone or scope of work.

- If there is the possibility of confusion about the permit.

- All field changes will be briefed by the RI.

- Once a field change has been noted in the LOTO Permit Database, the “print” button will disappear and the permit will need to be updated before it is implemented again.

Work Process J. Shift Changes and Transfer of Control

- Shift changes and transfer of control present additional challenges and barriers to proper communication in a complex LOTO situation. It is imperative that the Responsible Individual (RI) makes every effort to sufficiently manage the scope of work and the extent of the LOTO Safe Zone.

- If equipment will remain locked out after the end of a shift, and work will continue by the incoming shift, an orderly transfer of control of the isolations between LOTO Authorized Persons from the outgoing and incoming shifts must be performed.

- If the simple LOTO method was used, a shift change does not require transitioning to a complex LOTO with an assigned Responsible Individual.

- The RI for the LOTO must manage all shift changes. Transfer of control from one RI to another must occur separately from the shift change process to minimize confusion.

- Shift Change

- It is recommended, but not required, that all LOTO Authorized Persons in the outgoing shift remove their personal locks prior to going home at the end of the shift. The RI locks must stay in place to maintain continuity of the lockout. The lead worker or supervisor may also maintain a personal lock as desired.

- The outgoing shift RI must ensure that the incoming shift is updated on the progress of work from the outgoing shift. All changes in scope of work and the LOTO Safe Zone during the previous shift must be thoroughly explained to the incoming shift.

- Note that an administrative lock alone is not sufficient to maintain the integrity of a LOTO. As the LOTO Authorized Persons from the outgoing shift remove their personal LOTO locks, the RI must ensure that the RI locks remain in place.

- It is strongly suggested that a LOTO briefing is provided by the Responsible Individual prior to LOTO Authorized Persons proceeding with work at the beginning of each shift. An easy way to control this is to have each LOTO Authorized Person remove their lock(s) at the end of each day and sign the LOTO Log. The next morning when they return, they get a briefing and sign the LOTO Log again when they apply their LOTO locks and tags.

- Transfer of Control when an RI is involved

- The outgoing RI may transfer control of the LOTO to an incoming RI at any time either before or after the LOTO is completely established. Transfer of control is not permitted while the LOTO is being established or during any modification, such as a field change or temporary restoration of power for testing or repositioning.

- The outgoing RI must thoroughly brief the incoming RI on the status of the LOTO, including all isolations, energy dissipation devices, scope of work, completion status of the work, and expected changes to the LOTO that will be required as the work progresses. The incoming RI must inspect all isolations related to the LOTO and verify that each is properly locked out. At each energy isolation, the incoming RI must apply his or her RI lock first, and then the outgoing RI must remove his or her lock.

- When the incoming RI is satisfied that he or she is fully briefed on all aspects of the LOTO, the incoming RI must agree to assume the role of RI for the LOTO. The outgoing RI must then hand over the LOTO procedure to the incoming RI as part of the transfer. If transferring a group LOTO, the outgoing RI must also transfer all related lockboxes and procedures. Once transferred, the incoming RI assumes all RI responsibilities for the LOTO.

- Re-verification of Zero Energy State

- As long as the RI locks remain in place on the isolations (or if in the case of a group LOTO with a lockbox, the group locks remain in place on the isolations, and the RI lock remains in place on the lockbox), then re-verification of zero-energy state is not required at the beginning of each shift or upon transfer of control. Should any isolation become unlocked at any time, re-verification of zero-energy state is required prior to allowing any LOTO Authorized Person to apply their personal LOTO lock.

- Supplementary Voltage Checks may be performed at any time, and must be performed under certain conditions outlined in the Electrical Safety Manual, section 9.5. If the equipment is discovered energized again, the worker shall immediately stop work, notify the division ESO/ESA and notify the Laboratory ESO. Do not proceed with work. This is a formal stop work condition. Establish a barricade and/or an attendant around the area.

Work Process K. Temporary Partial Restoration

- Temporary partial restoration is the process of restoring energy to a part of the system without clearing the entire LOTO. This is only done for a short period of time, under continuous supervision by an assigned Responsible Individual (RI).

- This applies to a complex LOTO with two or more isolations and may be helpful when the equipment needs some level of energized testing or repositioning. Examples include:

- Energized testing

- Troubleshooting and diagnostics

- Rotation checks

- Rotating or repositioning a device for inspection

- Fan wheel balancing

- RI Steps for Temporary Restoration for Testing or Repositioning

- Notify the Affected Persons.

- Direct all LOTO Authorized Persons to stop work, replace required guards or establish a barricade around the hazard zone, and clear the equipment of tools and materials.

- Perform a LOTO briefing with all LOTO Authorized Persons participating in the lockout.

- Direct all LOTO Authorized Persons to remove their personal LOTO locks from the isolations that will be temporarily energized.

- Remove all stored energy dissipating devices (grounding/shorting conductors, hooks, or wands).

- Remove the RI lock.

- Energize and proceed with testing or repositioning.

- Once the testing or repositioning is complete, reestablish the LOTO, following all steps in Work Process F or Work Process G as required.

- Apply the RI lock.

- Perform a LOTO briefing with all LOTO Authorized Persons participating in the lockout.