Contents

Approved by Rafael Brown

Revised 5/21

36.1 Policy

36.2 Scope

36.3 Applicability

36.4 Exceptions

36.5 Roles and Responsibilities

36.6 Definitions

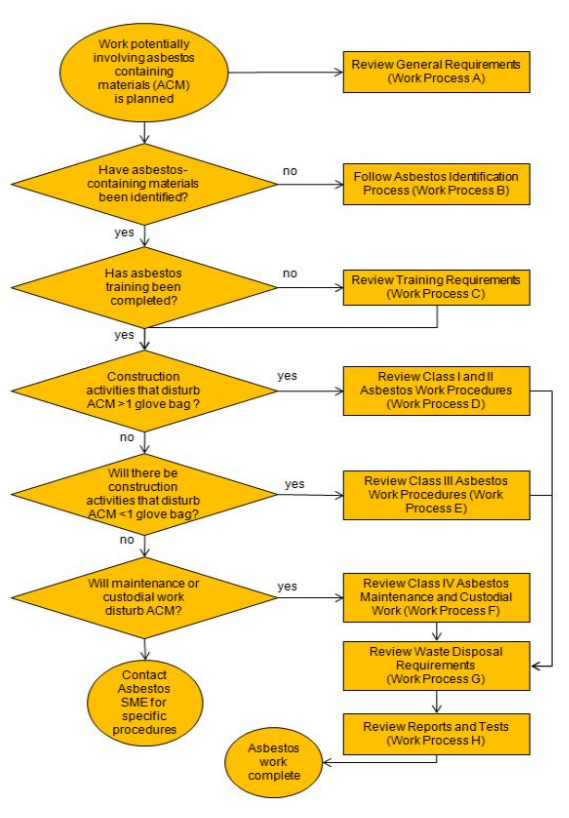

36.7 Required Work Processes

- Work Process A. General Requirements

- Work Process B. Asbestos Identification Process

- Work Process C. Training Requirements

- Work Process D. Class I and II Asbestos Work

- Work Process E. Class III Asbestos Work

- Work Process F. Class IV Asbestos Maintenance and Custodial Work

- Work Process G. Waste Disposal Requirements

- Work Process H. Reports and Tests

36.8 Source Requirements

36.9 Reference Documents

36.10 Appendices

Note:

🚩🚩 Denotes a new section

🚩 Denotes the beginning of changed text within a section

🛑 Denotes the end of changed text within a section

___________________

36.1 Policy

Berkeley Lab’s Asbestos Program manages the presence of asbestos-containing material (ACM) at the Laboratory site by:

- Mandating building survey and employee monitoring requirements for asbestos

- Communicating the presence of asbestos and potential exposures via signage and other written communication

- Listing engineering controls, training, and personal protective equipment (PPE) requirements for people and activities that will involve ACM

- Providing removal and repair guidance for ACM

36.2 Scope

This plan was developed to ensure that exposure to asbestos by Lawrence Berkeley National Laboratory (Berkeley Lab) employees, visitors, and subcontractor employees is minimized. Handling of asbestos or ACM must be in conformance with this plan. The Asbestos Program contains elements specifically required by laws and regulations, and additional requirements necessary to safely and effectively manage asbestos at Berkeley Lab.

36.3 Applicability

This program applies to All Berkeley Lab employees, affiliates, visitors, and subcontractors.

36.4 Exceptions

None

36.5 Roles and Responsibilities

|

Roles |

Responsibilities |

|

Building Managers |

Notify Environment, Health and Safety (EHS) of suspected or known ACM that may pose a health hazard |

|

Environmental Protection Group (EPG) |

|

|

Facilities Division |

Responsibilities related to Asbestos Bulk Sampling:

|

|

EHS Asbestos Program Industrial Hygienist |

|

|

Health Services Group |

|

|

Supervisors of employees who routinely work with or may disturb ACM |

|

|

Waste Management Group |

|

36.6 Definitions

36.7 Required Work Processes

Work Process A. General Requirements

- Background

- Asbestos is a generic term referring to fibrous mineral silicates that were used extensively from about 1900 until very recently in the manufacture of construction and industrial products. Some products are still manufactured with a significant asbestos content. Work Process B lists various products that have been manufactured with asbestos. This list is not exhaustive, other products not listed may also contain asbestos.

- Asbestos-containing materials can be divided into two general categories: friable and nonfriable.

- Friable ACM products are those that can be readily crumbled or powdered by hand pressure, and are of more concern than nonfriable ACM because of the greater ease of fiber release. Examples of friable ACM include pipe insulation, sprayed-on acoustical insulation, and sprayed-on fireproofing. Intact and sealed friable asbestos materials are considered nonfriable and do not pose a health risk if they are undisturbed and undamaged.

- Non-friable ACM generally possesses a strong binder such as cement or vinyl, which stabilizes the asbestos, reducing the likelihood of generating airborne asbestos dust. However, specific actions such as sanding, grinding, cutting, or drilling of nonfriable asbestos can result in the release of asbestos fibers. Examples of nonfriable asbestos include intact vinyl asbestos floor tiles, roofing felts/shingles, and asbestos cement products such as transite panels and pipes.

- Management of the Asbestos Program. The EHS Construction and Maintenance Field Support Group manages the institutional Asbestos Program and its programmatic elements. Actual asbestos support functions, provided by the Facilities Division or its subcontractors, are managed directly by the Facilities Division. This will entail active involvement by EHS and Facilities, with Berkeley Lab asbestos-control activities relating to demolition, renovation, maintenance activities, or other instances involving the possible disturbance of ACM.

- Asbestos as an Inhalation Hazard. Asbestos is primarily an inhalation hazard and a demonstrated human carcinogen. Employee exposure to airborne asbestos should be limited to levels that are “As Low As Reasonably Achievable” (ALARA) and must be limited to levels below applicable occupational exposure limits (see below).

- Asbestos-Related Diseases. Asbestos-related diseases caused by the inhalation of fibers typically occur 10 to 45 years after exposure. Asbestos does not cause any acute (immediate) effects, except skin warts that are mentioned below.

- Asbestosis — permanent fibrotic scarring of lung tissue, which results in a reduced ability to breathe, cardiovascular failure, and in severe cases, death.

- Lung Cancer — occurs more often in people exposed to asbestos than in non-exposed groups. This effect of asbestos exposure is greatly magnified by cigarette smoking.

- Mesothelioma — cancer of the lining of the chest and abdominal cavity. A rare disease that occurs almost exclusively in those exposed to asbestos.

- Skin warts — single asbestos fibers embedded in the skin may cause noncancerous warts. They heal when the fiber is removed.

- Hygiene Facilities

- For Class 1 asbestos jobs involving more than 25 linear or 10 square feet of TSI or surfacing material, there must be a decontamination area (8 CCR 1529 (j)) consisting of an equipment room, shower area, and clean room, in series and connected to the Regulated Area. Employees must enter and exit through the decontamination area.

- For Class 1 asbestos jobs involving less than 25 linear or 10 ft2, and Class 2 or 3 work that is above the PEL or where there is no negative exposure assessment, an equipment room adjacent to the Regulated Area must be constructed.

- The floor area and horizontal work surface must be constructed of 6-mil plastic (minimum), and be large enough to accommodate the cleaning of equipment and surfaces of waste containers.

- Work clothing must be HEPA vacuumed before it is removed and employees must enter or exit through the equipment room.

- Class IV work technically does not occur at Berkeley Lab and therefore does not require decontamination facilities. Employees trained at this level (i.e., Berkeley Lab Awareness Level Training – EHS0339) will not work in Regulated Areas or be involved in the cleanup of ACM or PACM.

- Labeling and Posting

- Identified (by laboratory analysis) friable ACM found to contain greater than 1.0 % asbestos can be labeled, when feasible, as shown in Appendix A, Figure A-1.

- Warning signs can be posted at the outside perimeter of each regulated area as shown in Appendix A, Figure A-2.

- Medical Surveillance. Any Berkeley Lab employee identified as being exposed to airborne asbestos for a combined total of 30 or more days per year engaged in Class I, II, and III work, or who is exposed at or above a permissible exposure limit, will be provided medical surveillance as described in 8 CCR 1529 or 8 CCR 5208 by the Health Services Group. All other employees who enroll in and complete predefined asbestos classes will be offered voluntary medical surveillance.

- New Products Containing Asbestos. No new asbestos-containing construction products will be procured or installed at Berkeley Lab without prior review by the EHS Asbestos Program.

- Protective Clothing

- Employees who may be exposed to airborne asbestos levels exceeding the PEL or excursion limit will be provided protective clothing (e.g., disposable coveralls, gloves, shoe coverings, safety glasses, etc.) and work equipment at no cost.

- Contaminated clothing used in areas that may exceed the PEL or excursion limit will be transported in sealed poly bags and disposed of as asbestos-containing waste.

- Regulatory Agency Notification

- The BAAQMD requires a minimum of 10 working days’ notice prior to any building demolition.

- The same notification requirement applies to building renovations involving RACM removal over certain reportable quantities.

- An additional category of notification is for a series of small activities involving RACM that individually do not trigger notification, but collectively do. This is called a cumulative notification and it is submitted and paid for by the Facilities Division once per year.

- To ensure compliance with BAAQMD’s notification requirements:

- The Environmental Services Group (ESG) will be informed of every demolition by Facilities, whether or not it involves asbestos.

- Outside contractors who perform work reportable to BAAQMD (i.e., greater than 100 linear, 100 square or 35 cubic feet) will send BAAQMD application forms to the Facilities Project Manager for EHS ESG review prior to the subcontractor submitting the required notice to the BAAQMD.

- The BAAQMD requires a minimum of 10 working days’ notice prior to any building demolition.

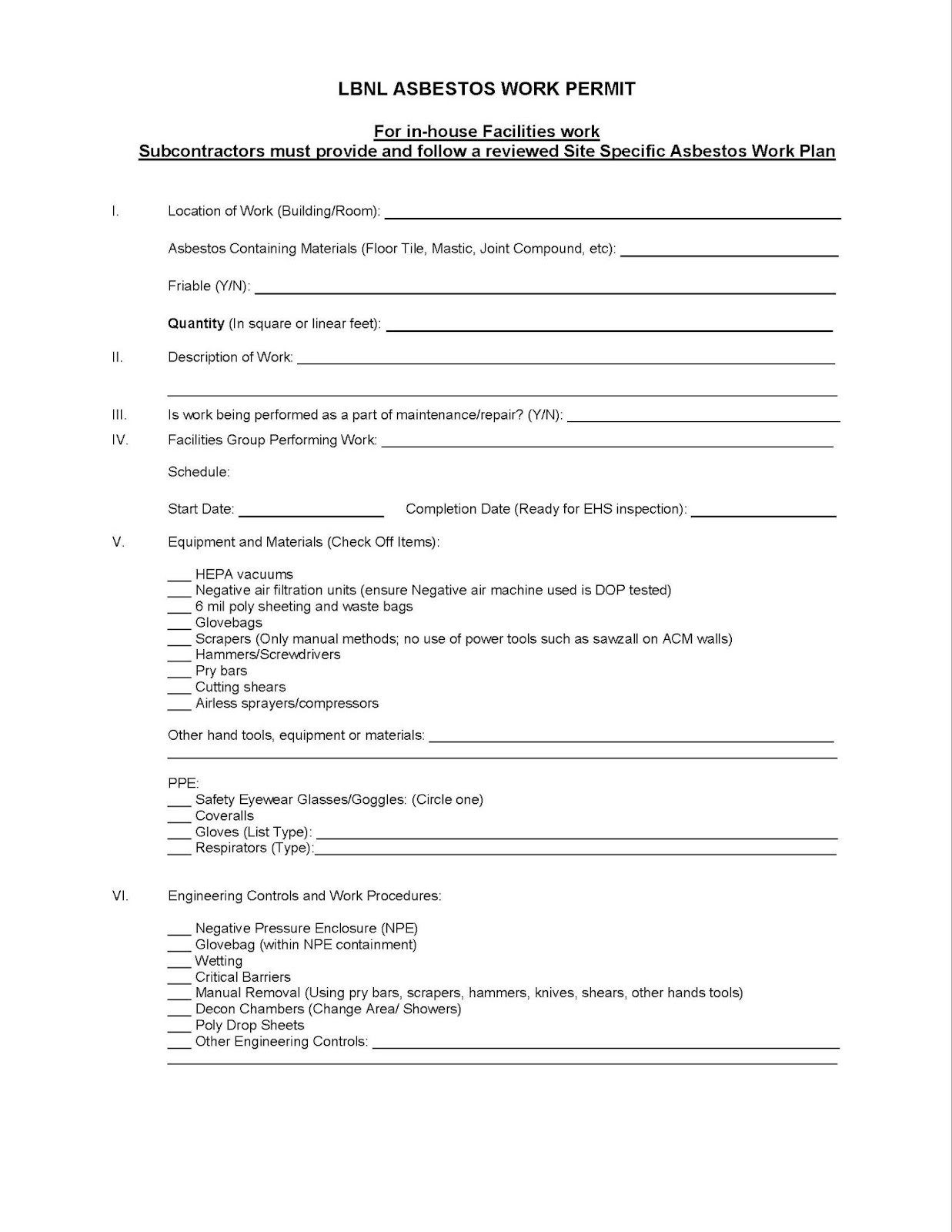

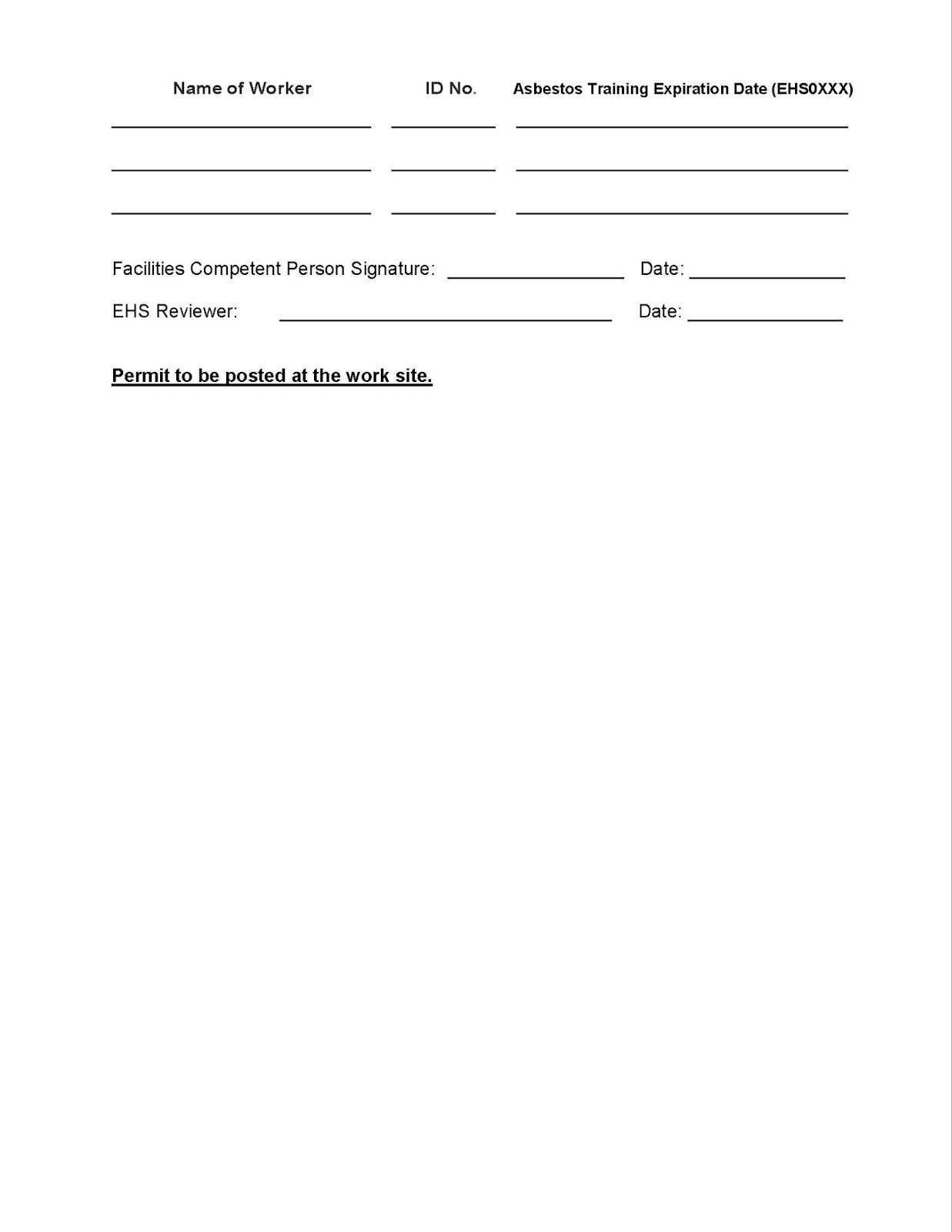

- Documentation for In-House Asbestos Projects (Asbestos Work Permit)

- The LBNL Asbestos Work Permit form in Appendix B is to be used to document in-house projects performed by Facilities crafts that involve the disturbance of ACM or PACM. This permit is used to specify the controls, PPE, and scope of each project performed in-house. The supervisor initiates the process and obtains the Berkeley Lab EHS industrial hygienist’s review signature prior to the start of work. A running log of these permits is maintained by the EHS Asbestos Program Industrial Hygienist.

- Respirators

- Air-purifying negative-pressure respirators used by Berkeley Lab personnel who may be exposed to asbestos above the PEL or excursion limit must be fit-tested prior to conducting asbestos work. This is in addition to the other aspects of the Respiratory Protection Program. Call EHS for respirator fit testing and training.

- Powered air-purifying respirators shall be provided free of charge in lieu of a negative-pressure respirator if an employee requests one.

- Respirators shall be used in all of the following circumstances:

- Class I asbestos work

- Class II work where the ACM is not removed intact

- Class II & III work where wet methods are not used and there is not a negative exposure assessment

- Class III work where TSI or surfacing material that contains or may contain asbestos is removed

- For any class or type of asbestos related work or disturbance activity at the discretion of EHS

- Respirator Selection Table.The following table, which represents minimum requirements, should be used to select respiratory protection.

| Airborne Concentration of Asbestos | Required Respirator |

| Not in excess of 1 f/cc (10X PEL) | Half-mask air-purifying (not disposable) with HEPA filters |

| Not in excess of 5 f/cc (50X PEL) | Full-face air-purifying respirator with HEPA filters |

| Not in excess of 10 f/cc (100X PEL) | Powered air-purifying with HEPA filters |

| Not in excess of 100 f/cc (1000X PEL) | Full face piece supplied air respirator operated in pressure-demand mode |

| Greater than 100 f/cc (1000X PEL) | Full face piece supplied air respirator in pressure demand, equipped with 5-minute escape bottle |

- Flooring Material Maintenance

- Rubber wheels (i.e., not plastic) should be used on chairs that are in contact with resilient flooring (e.g., linoleum, floor tiles, sheet flooring). The purpose of this requirement is to prevent floor abrasion and the subsequent potential creation of asbestos-containing dust. The Facilities Work Request Center at ext. 6274 is available for assistance in the replacement of wheels. The cost of the rubber wheels will be at the expense of the owner of the chair. Alternatively, chair owners can contact the EHS Ergo Program for the replacement of chair casters.

- Sanding of the flooring, its backing, or mastic, is prohibited.

- Stripping of floors must be conducted using low-abrasion pads at speeds lower than 300 rpm, and wet methods.

- Burnishing or dry buffing may be performed only on flooring that has sufficient finish so that the pad cannot contact the ACM.

- Dust and debris in an area containing visibly deteriorated ACM shall not be dusted, swept dry, or vacuumed without the use of a HEPA vacuum by AHERA asbestos trained Facilities workers.

- Roofing Products – Asphalt

- Asphalt roofing products containing asbestos are nonregulated (Category I, nonfriable) unless:

- They are or will become friable.

- They will be subjected to sanding, drilling, grinding, cutting, or abrading.

- Such nonregulated asphalt roofing products do not need to be reported prior to demolition or renovation activities unless they will become friable as part of the work or they are severely weathered and considered friable.

- Waste-disposal sites may have individual internal requirements that exceed legal disposal requirements. Contact the Waste Management Group for guidance concerning bins, labeling and wrapping requirements, etc., before starting work.

- Asphalt roofing products containing asbestos are nonregulated (Category I, nonfriable) unless:

- Asbestos Flooring Material

- Covering asbestos flooring material (e.g., VAT tiles, linoleum, etc.,) must be avoided, when feasible, to prevent potential inhalation exposure risks to employees and to prevent costly change orders due to materials being missed as part of future renovation projects. In cases where these materials are covered, Facilities will notify EHS, which will enter this information into the Hazard Management System (HMS).

- As part of project planning and design, and when feasible, asbestos flooring material and mastic shall be removed prior to renovation projects to prevent abrading, scratching, wearing, breaking, or any other type of disturbance of the material.

- When carpet to be removed is glued to asbestos flooring materials, if more than a few tiles pop up, the carpet removal must stop and be removed inside a HEPA-filtered, negative-pressure containment. Contact an EHS industrial hygienist for additional consultation. Facilities Construction Managers must evaluate the condition and risk of carpet pulling up ACM floor tiles as part of carpet removal projects.

- Concrete Material

- Only the following suspect materials will be sampled for asbestos as part of demolition and renovation work:

- Structural component that supports a heavy load including, but not limited to: Interior concrete structural walls, foundation slabs and retaining walls.

- Recycled concrete if >160 sq. ft.

- Suspect concrete:

- Heat resistance situations / locations (e.g., boiler pads)

- Parge coat

- Lightweight concrete on roof

- Reddish / Pinkish concrete layers (Used in wet location areas)

- Concrete samples will be analyzed by PLM vs CARB 435.

- Only the following suspect materials will be sampled for asbestos as part of demolition and renovation work:

Work Process B. Asbestos Identification Process

- For identification of asbestos content in materials, contact the EHS Construction and Maintenance Field Support Group.

- For concerns regarding the safety of potential asbestos-containing materials, contact the EHS Asbestos Program.

- Examples of Materials Manufactured with Asbestos

- Asbestos panels and pipes (e.g., transite materials)

- High-temperature gaskets

- Pipe insulation (block, corrugated aircell, etc.)

- Mastic for vinyl flooring

- Vinyl floor tiles and sheet vinyl flooring

- Wallboard (Sheetrock), taping or joint compounds and skim coats

- Electric wiring insulation

- Spray-applied fireproofing and insulation

- Roofing felt/shingles/flashing

- Automotive brake linings and pads

- Ceiling tiles

- Fire-resistant gloves, clothing

- HVAC duct insulation and tape

- Linoleum and other resilient flooring

- Paint

- Fire-door insulation

- Window glazing and caulking

- Plaster/stucco

- Elevator/crane brake shoes

- Building Surveys/Repairs

- Buildings constructed after 1981 generally do not contain friable asbestos; however, an EHS industrial hygienist must be consulted beforehand for all renovation and demolition projects since there are no end dates for building survey purposes.

- The Facilities Division is responsible for the repair of damaged or deteriorated (unsealed ends, nicks, loose pieces of insulation, abraded floor tiles, etc.) friable and nonfriable ACM. EHS, in collaboration with Facilities, will determine what type of repair is necessary and how soon it needs to be performed. An industrial hygienist will be available for consultation on these decisions.

- Pre-renovation / Demolition: Facilities is responsible for ensuring the affected structure or areas are surveyed for ACM prior to any demolition or renovation, per 40 CFR 61.145 and BAAQMD 11-2-303.8.

- If suspected ACM has not undergone laboratory analysis, it should be assumed to contain asbestos and treated accordingly.

- Bulk Sampling

- The testing, evaluation, and sample collection of materials for asbestos analysis must be conducted by an accredited asbestos building inspector (40 CFR Part 763) or by a Certified Industrial Hygienist.

- Analysis of these samples must be performed by persons or laboratories with proficiency demonstrated by participation in the National Voluntary Laboratory Accreditation Program (NVLAP).

- Employee Notification. Air-monitoring results from an industrial hygienist must be given in writing to the affected employee and his or her supervisor within five working days of their receipt.

- Exposure Monitoring and Job-site Clearance Levels

- The current Cal/OSHA PEL is 0.1 fibers per cubic centimeter (f/cc) of air averaged over an eight-hour day. The excursion limit for any 30-minute exposure is 1.0 f/cc of air.

- Initial monitoring of Berkeley Lab employees who are or who may be reasonably expected to be exposed to airborne asbestos concentrations exceeding the PEL or excursion limit will be performed by an industrial hygienist.

- Monitoring may be discontinued when results show that employee exposures are consistently below the PEL and excursion limit.

- Initial monitoring will be repeated whenever there has been a change in the control equipment, process, personnel, or work practices that may result in new or additional exposures.

- Acceptable job-site clearance levels are 70 structures per square millimeter (st/mm2) by TEM or 0.01 fibers per cubic centimeter (f/cc).

- Clearance sampling is not required for small-scale, short-duration projects and is performed at the discretion of EHS.

- Identification of ACM in Buildings

- Prior to remodeling, modifying, demolishing, or otherwise disturbing any facility component, the job site will be visually inspected by a qualified AHERA asbestos building inspector.

- If ACM is potentially present and an adequate prior survey of the area has not been conducted, a survey must be performed to identify any ACM that may be disturbed by the planned work.

- Any such materials identified as ACM will be removed or protected from disturbance before the work can proceed. (See 40 CFR 61.145[c] and BAAQMD 11-2-303.)

- Materials suspected of being ACM but not sampled will be assumed to contain asbestos and treated accordingly. This is most appropriate when the task is very limited in scope (e.g., a small spill <1 ft2, floor tiles <10 ft2) and the cost and time spent collecting and analyzing the samples is a significant part of, or exceeds, the cost of performing work.

- HEPA Vacuum Cleaner or Negative Air Machine Maintenance

- Maintenance on the interior components of HEPA vacuums or negative air machines, by LBNL asbestos worker trained staff, must be performed under effective controls while outside of buildings in open areas away from passers-bye or other work activities. A small, HEPA filtered, negative pressure enclosure should be built by LBNL asbestos worker trained staff to open the units and perform any necessary bag or filter changes while wearing disposable coveralls and at a minimum, a half mask, air-purifying respirator equipped with P100 filters. Alternatively, the construction of the small, HEPA filtered negative pressure enclosure can be constructed by an outside asbestos abatement subcontractor in order for Berkeley Lab asbestos trained workers to perform the maintenance work or this can also be subcontracted out to the asbestos abatement subcontractor.

- Personal air sampling during maintenance work will be performed by LBNL EHS staff for LBNL asbestos trained workers who perform the work or by the asbestos abatement subcontractor if their employees perform the work.

- Clearance air sampling is not required.

- Repair work is discouraged. Units should probably be replaced to avoid prolonged or repeated steps to repair vacuums or negative air machines.

- Sheetrock (drywall)

- When a demolition or renovation impacts a wall system composed of Sheetrock, joint compound, and tape, a composite sample will be taken of the wall material for PLM analysis or presumed to contain asbestos without sampling.

- If the composite sample result indicates a trace amount of asbestos, and/or the joint compound analysis indicates > 1% asbestos content, the result is considered friable ACM and an EHS industrial hygienist must be contacted for further guidance before starting the work.

- Typically point counting is not pursued by Berkeley Lab since many Cal/OSHA worker protection requirements are still required at any asbestos concentration in the material and there are perception risks related to disposing of sheetrock that contains less than 1% in regular trash dumpsters.

- In special cases where sheetrock wall systems are point counted and the results are less than 1% asbestos, the material is not regulated by BAAQMD, EPA, or DTSC; however, interpretation of results and guidance regarding sheetrock analysis is at the discretion of the EHS Asbestos Program.

- Work associated with disturbing greater than 1 square foot of sheetrock tested by PLM and found to contain greater than 1% asbestos, or presumed ACM without sampling, is considered friable ACM disturbance that requires a HEPA filtered, negative pressure enclosure per BAAQMD requirements.

- Facilities craft / trades workers who have Class III (4 hr) training are able to disturb up to 36 square inches of sheetrock wall systems, as part of their trade, with engineering controls such as use of HEPA vacuum at the cut point, tool attachments to HEPA vacuums, wet spray method, damp sponge method, shaving cream or other effective means of dust control.

Work Process C. Training Requirements

|

Role |

Required Training |

|

Facilities employees routinely engaged in activities that may contact, but not disturb, asbestos containing building materials |

Berkeley Lab annual asbestos awareness class. Although not classified as Class IV work, since dust, waste or debris from Class I-III work is not performed, the training will cover:

|

|

Employees identified as being potentially exposed to airborne asbestos levels above the PEL or excursion limit |

Cal/OSHA-approved training per 8 CCR 5208(j)(7) and 8 CCR 1529(k)(9) |

|

Employees performing bulk sampling |

EPA-approved building inspector course or be a Certified Industrial Hygienist (8 CCR 1529(k)(5)(B)(2)) |

|

Asbestos Program Manager |

|

|

Industrial Hygienist whose specialty area is asbestos |

|

|

Class I Abatement Workers |

Workers must have AHERA worker (32 hours) training. |

|

Class II Abatement Workers |

Workers must have AHERA worker (32 hours) training. |

|

Class III Workers (16 hr) |

Supervisor and workers must be trained at the EPA 16-hour Operations & Maintenance level or higher. |

|

Class III Workers (4 hr) |

Berkeley Lab craft employees who may disturb small, incidental amounts of building materials that may contain asbestos as part of their trade |

|

Class IV Workers |

Trained to Berkeley Lab’s awareness level training for hazard communication purposes |

Work Process D. Class I and II Asbestos Work

- Class 1 Asbestos Work

- Definition: Removal of thermal system insulation (TSI) or surfacing material greater than one glove bag. Note: Any change or deviation from the below-specified control methods must be approved in writing by a CIH.

- Training: Abatement workers will be supervised by a “competent” person who meets the requirements of 8 CCR 1529 (b). Workers must have AHERA worker (32 hours) training.

- Air Sampling: Air monitoring required unless a negative exposure assessment has been performed for the entire operation. Clearance air sampling is required before negative-pressure enclosure is removed and the work area is re-occupied. The acceptance clearance level is <70 structures/mm2 by TEM. PCM clearance samples may be acceptable for small containments.

- Regulated Area: Required for all work

- PPE/Respirators: Disposable coveralls, shoe covers, and respirator. Respirators must always be worn. See Respirator Selection Table in Work Process A, Section 11, for guidance.

- Work Requirements

- The work location will be identified as a “Regulated Area.”

- An HVAC system inside the regulated area is isolated by sealing with a double layer of 6 mil plastic.

- Impermeable drop cloths will be placed on surface beneath all removal activity.

- Jobsite visual safety observations will be completed by an EHS industrial hygienist, Facilities supervisor or Construction Manager or abatement foreman before and during work.

- Negative-Pressure Enclosure: If the amount of ACM to be removed is more than 25 linear or 10 square feet, and exposure monitoring has shown that the PEL may be exceeded, a negative-pressure enclosure is required. Listed below are the requirements for the enclosure.

- A minimum of -0.02 inches of water differential and at least four air changes per hour must be maintained inside of the enclosure.

- Negative-pressure machines shall be exhausted to the outside of the building, if feasible.

- Full decontamination with an equipment room, shower area (with hot and cold water), and clean room in series is required at the work site (8 CCR 1529 (j)).

- Glove Bag Systems

- Glove bags shall be used to remove ACM and PACM from straight runs of piping. Specifications for the glove bags and their use:

- Made of 6-mil-thick plastic and seamless at the bottom

- Installed so that it completely covers the circumference of the pipe

- Smoke-tested for leaks and any leaks sealed prior to use

- Used only once and not moved

- Not used on surface exceeding 150º F

- Collapsed by removing air with a HEPA vacuum prior to disposal

- Loose and friable material adjacent to the glove bag shall be wrapped and sealed in two layers of 6-mil plastic, or otherwise rendered intact.

- At least two persons shall perform Class 1 glove bag removals. Note: This is required in 8 CCR 1529 (g)(5)(B)(2).

- Glove bag removal operations shall be performed inside HEPA-filtered negative-pressure enclosures, when feasible, given the greater risk of asbestos fiber releases associated with glove bag work.

- Glove bags shall be used to remove ACM and PACM from straight runs of piping. Specifications for the glove bags and their use:

- Class II Asbestos Work

- Definition: Removal of ACM other than TSI or surfacing materials. Examples of this type of work include the removal of roofing, flooring, mastics, gaskets, transite, wallboard, etc.

- Training: Abatement workers will be supervised by a “competent” person who meets the requirements of 8 CCR 1529 (b). Workers must have AHERA worker training (32 hours). If the workers will remove/disturb only one type of building material (e.g., roofing, flooring, transite) they can be trained at a Class IV level, with additional training on specific work practices and engineering controls. This course will include hands-on training and be at least eight hours long.

- Air Sampling: Required unless there is a negative exposure assessment. Clearance air sampling may be required before the work area is occupied. The acceptance clearance level is <70 structures/mm2 by TEM. PCM clearance samples may be acceptable for small containments.

- PPE / Respirators: Same as for Class 1 work if the PEL is exceeded, wet methods are not used, or if the material is not removed substantially intact.

- Roofing: Shall be removed following the work practices listed below:

- Removed intact to the extent feasible

- Wet methods used when feasible

- Cutting machines misted continuously during use, unless a competent person determines misting decreases worker safety

- Loose dust left by sawing operations HEPA-vacuumed immediately

- Unwrapped or unbagged roofing material immediately lowered to the ground via covered, dust-tight chute, crane, or hoist. Wrapped or bagged material lowered to the ground at the end of the work shift.

- Roof-level heating and ventilating air-intake sources isolated by sealing and wrapping with two layers of 6-mil plastic or equivalent.

- Floor Tile Removal: Floor tiles must be removed following the work practices listed below:

- Follow requirements for Class 1 work; however, Section 1.g.iii of this work process (i.e., shower/equipment room) may be omitted if a negative exposure assessment has shown that the work is less than the PEL. In addition, the following list applies:

- Sanding of flooring, its backing, and the mastic is prohibited.

- Vacuums equipped with HEPA filter, disposable dust bag, and metal floor tool (no brush) must be used to clean floors.

- Resilient sheeting must be removed by cutting while wetting, and wetting during delamination.

- All scraping of residual adhesive or backings must be performed using wet methods.

- Dry sweeping and mechanical chipping are prohibited.

- When tiles are heated and removed intact, wetting may be omitted.

- Follow requirements for Class 1 work; however, Section 1.g.iii of this work process (i.e., shower/equipment room) may be omitted if a negative exposure assessment has shown that the work is less than the PEL. In addition, the following list applies:

- Transite Panels, Siding, or Shingles (i.e., asbestos-cement products): The following work practice shall be followed:

- Cutting, abrading, or breaking is prohibited; if this is not possible, perform as Class 1 Asbestos Work. (Contact EHS Asbestos Program for drilling transite.)

- Each panel or shingle must be sprayed with amended water prior to removal.

- Unwrapped or unbagged panels, etc., must be lowered to the ground, or wrapped in two layers of 6 mil plastic sheeting and lowered to the ground at the end of the project and labeled with asbestos danger labels.

Work Process E. Class III Asbestos Work

Class III (16 hr) Asbestos Work

- Definition: Repair and maintenance activities that disturb ACM (or PACM), includes TSI and surfacing material and the cleanup of ACM dust or debris. The amount disturbed must fit in one glove bag or waste bag less than 60 inches in width. Examples include:

- Single glove bag removal of pipe insulation

- Patching of pipe insulation

- Decontamination of surfaces (spills etc.)

- Removal of 1 square foot or more of RACM, using a HEPA filtered, negative pressure enclosure

- Training: Supervisor and workers trained at the EPA 16-hour Operations & Maintenance level or higher

- Air Sampling: Shall be performed as needed to document potential exposures.

- Regulated Areas: Not required, unless the PEL is exceeded or a negative exposure assessment has not been performed.

- PPE / Respirators: Required as for Class 1 work when TSI or surfacing material is disturbed, the PEL is exceeded, or when a negative exposure assessment has not been performed. See Respirators section in Work Process A for guidance in selecting a respirator.

- Work Requirements

- Post signs in such a manner that unauthorized persons will avoid entering the asbestos work area. (See Appendix A, Figures A-2 and A-3)

- Isolate the work area to the extent possible by closing doors, windows, or other openings.

- Wear disposable coveralls, shoe covers, and half-mask respirator with HEPA filters, as appropriate.

- Lightly mist any loose asbestos or asbestos debris with an appropriate wetting agent. Pick up or vacuum (HEPA) up loose material or dust. Wet-wipe hard surfaces after vacuuming. Note: The exposed hose end of the HEPA vacuum should be taped shut when the vacuum is not in use.

- Cover surfaces under the area to be abated with a sheet of 6-mil-thick plastic sheeting adequate to catch any debris.

- Wet the material thoroughly before handling. For pipe insulation removal, use a glove bag.

- Local exhaust ventilation should be used when feasible.

- Whenever the work involves the disturbance of TSI or surfacing materials, impermeable plastic barriers, mini-enclosures or glove bags shall be used to isolate the work area.

- Use only hand tools to remove or repair material.

- Seal all exposed ACM surfaces with a coating of penetrating encapsulant and a layer of bridging encapsulant.

- Vacuum off protective clothing, and dispose of as asbestos-containing waste material. These materials should be double-bagged in 6-mil plastic bags and labeled as shown in Appendix A, Figure A-1. Rubber boots that are to be reused must be wet-wiped after use. Respirators should be removed last, wet-wiped, and placed in a storage bag. Filters should be removed from the respirator and disposed of, or the respirator filter’s air inlets should be sealed with tape, if left on the respirator, or stored in a separate storage bag. Dispose of the wet-wipe material and the respirator filters as asbestos-containing waste material.

- Clearance air-sampling is generally not required for work at this scale; however, this is left to the discretion of the EHS industrial hygienist. Contractors performing this work will monitor their own workers. Removed ACM shall be disposed of in accordance with Work Process G.

- Removal of greater than 1 square foot of RACM triggers the need for a HEPA filtered, negative pressure mini-containment.

Class III (4 hr) Asbestos Disturbance by Facilities Crafts / Trades

- Definition: Repair and maintenance activities as part of Facilities crafts / trades workers that disturb incidental amounts of ACM (or PACM), excluding TSI and surfacing material and the cleanup of ACM dust or debris. Examples include:

- Cutting a small hole in a wall to install a light switch or wall receptacle

- Drilling small holes in a wall to fasten unistrut to the wall to run electrical conduit

- Repairing three missing or broken floor tiles

- Training: Employees receive four hours of asbestos training annually by an outside training consultant.

- Air Sampling: Shall be performed as needed to document potential exposures.

- Regulated Areas: Not required, unless the PEL is exceeded.

- PPE / Respirators: Typically not required for incidental disturbance and given administrative and engineering controls.

- Work Requirements

- Work is limited to incidental disturbance:

- <36 sq. inches of sheetrock

- <3 sq. feet of floor tile

- No disturbance of friable ACM, including, but not limited to fireproofing, TSI or surfacing materials

- 2 inch diameter holes in sheetrock, excluding transite materials

- Contact EHS for guidance for other materials that may need to be disturbed as part of work activities

- Controls Include:

- Use of tested asbestos HEPA vacuum at the drill point or use of local exhaust shroud with HEPA vacuum and tool

- Use of spray bottle with soap and water and spray as disturbance activity is taking place

- Use of damp sponge at disturbance point

- Use of shaving cream at disturbance point

- Use of dust bubble or other effective dust containment system

- Pick up or use tested HEPA vacuum to pick up loose material or dust.

- Wet-wipe hard surfaces after vacuuming. Note: The exposed hose end of the HEPA vacuum should be taped shut when the vacuum is not in use.

- Place larger debris in double zip lock bag or other poly bag and use duct tape to secured closed and place asbestos warning label on outside of bag. Contact the Facilities WAA owner and properly dispose of waste.

- Work is limited to incidental disturbance:

Work Process F. Class IV Asbestos Maintenance and Custodial Work

- Class IV Asbestos Work

- Definition: Defined by Cal/OSHA as maintenance and custodial activities where employees contact ACM or PACM, but do not disturb the material and activities to clean up dust, waste, and debris resulting from Class I, II, and III activities.

- Training: Since Berkeley Lab employees trained at this level do not clean up dust, waste, or debris from Class I-III activities, training is limited to Berkeley Lab’s awareness-level training for hazard communication purposes.

- Air sampling: Not applicable because employees are not disturbing ACM related to cleanup of dust, waste, and debris resulting from Class I-III work.

- Regulated Areas: None. Employees who are trained at this level will not work in a regulated area.

- PPE / Respirators: Not required. Employees who are trained at the Berkeley Lab awareness level will not work in Regulated Areas or perform work that disturbs ACM dust, waste, or debris.

- Work requirements: Wet methods. Since this type of work only involves contact with ACM flooring, see Work Process A, Section 12, Flooring Material Maintenance.

Work Process G. Waste Disposal Requirements

- Hazardous Waste – Friable Asbestos Containing 1% or Greater Asbestos

- All asbestos that is greater than 1% must be handled as hazardous waste. Hazardous asbestos waste must be thoroughly wetted before packaging, then packaged to prevent dispersion and to facilitate handling.

- The EHS Waste Management Group is responsible for determining the Hazardous Waste Handling Facility’s storage and labeling requirements, selecting the disposal site, and manifesting and maintaining disposal records. It will also assist in determining how best to package the waste for disposal and arranging site pickup.

- Packaging

- Labels: All containers of hazardous waste must bear the asbestos warning label (Appendix A, Figure A-1) and the “Hazardous Waste” label.

- Bags: Asbestos hazardous waste must be sealed inside two layers of 6-mil-thick plastic bags after thorough wetting. The excess air in the bag must be removed by a HEPA vacuum. The outer bag must be labeled as shown in Appendix A, Figure A-1.

- Drums: Wetted, asbestos hazardous waste can be contained in properly labeled Department of Transportation (DOT) spec. 17H 55-gallon steel drums equipped with polyethylene drum liner bags.

- Nonfriable Asbestos Waste (transite, floor tile, etc.), must be double wrapped or bagged in 6 mil plastic or other suitable means directed by EHS Waste Management and contain asbestos warning labels. Contact the EHS Waste Management Group for assistance with labeling, storage, and disposal requirements.

- All exposed RACM must be adequately wetted and kept wet during cutting, stripping, demolition, renovation, removal, handling, and disposal. Approval for dry removal of RACM must be received from the BAAQMD through the Environmental Services Group.

Work Process H. Reports and Tests

- Bulk Sampling

- The testing, evaluation, and sample collection of materials for asbestos analysis must be conducted by an accredited asbestos building inspector (40 CFR Part 763) or by a CIH.

- Analysis of these samples must be performed by persons or laboratories with proficiency demonstrated by participation in the National Voluntary Laboratory Accreditation Program (NVLAP).

- Employee Notification. Air-monitoring results from the industrial hygienist must be given in writing to the affected employee and his or her supervisor within five working days of their receipt.

- Exposure Monitoring and Job-site Clearance Levels

- The current Cal/OSHA PEL is 0.1 fibers per cubic centimeter (f/cc) of air averaged over an eight-hour day. The excursion limit for any 30-minute exposure is 1.0 f/cc of air.

- Initial monitoring of Berkeley Lab employees who are or may be reasonably expected to be exposed to airborne asbestos concentrations exceeding the PEL or excursion limit will be performed by an industrial hygienist.

- Monitoring may be discontinued when results show that employee exposures are consistently below the PEL and excursion limit.

- Initial monitoring will be repeated whenever there has been a change in the control equipment, process, personnel, or work practices that may result in new or additional exposures.

- Acceptable job-site clearance levels are 70 structures per square millimeter (st/mm2) by TEM or 0.01 fibers per cubic centimeter (f/cc).

- Clearance sampling is not required for small-scale short duration projects; however, the decision to require clearance is at the discretion of the EHS industrial hygienist.

- Air Sampling

- Class I and II Work: Air monitoring is required unless a negative exposure assessment has been performed for the entire operation. Clearance air sampling is required before the negative-pressure enclosure is removed and the work area re-occupied. The acceptance clearance level is <70 structures/mm2 by TEM. PCM clearance samples may be acceptable for small containments.

- Class III Work: Must be performed as needed to document potential exposures and is at the discretion of the EHS industrial hygienist.

36.8 Source Requirements

- 8 CCR 1529, Asbestos (Construction Safety Orders), Department of Industrial Relations

- 8 CCR 5208, Asbestos (General Industry Safety Orders), Department of Industrial Relations

- 29 CFR 1926.32, Definitions

- BAAQMD, Regulation 11, Rule 2, Asbestos Demolition, Renovation and Manufacturing

- 40 CFR Part 61, National Emission Standards for Hazardous Air Pollutants (NESHAP), Environmental Protection Agency (EPA)

- 40 CFR Part 763 (guidance), Asbestos Hazard Emergency Response Act (AHERA) – EPA regulations for schools

- Reg. 11, Rule 2, Asbestos Demolition, Renovation and Manufacturing Bay Area Air Quality Management District (BAAQMD)

- Title 22, California Code of Regulations, Hazardous Waste Disposal and Transportation, California Department of Toxic Substances Control (DTSC)

The interplay of EPA, Cal/OSHA, and BAAQMD regulations makes asbestos compliance somewhat complicated. Therefore, frequent consultation with an EHS Industrial Hygienist, the Environmental Protection Group, Waste Management Group, and/or Berkeley Lab Environmental Counsel on asbestos-related issues is encouraged.

36.9 Reference Documents

| Document number | Title | Type |

| 07.07.002.010 | Asbestos Management Plan | Plan |

36.10 Appendices

Appendix A. Asbestos Labels and Signs

Danger Contains Asbestos Fibers May Cause Cancer Causes Damage to Lungs Do Not Breathe Dust Avoid Creating Dust |

Figure A-1. Appropriate wording for labeling friable materials containing 1.0% asbestos by weight, or greater. This label is also appropriate for containers (including waste containers) that contain 1.0% or greater friable asbestos by weight. Waste containers holding RACM and asbestos-contaminated materials (such as protective equipment and clothing) must also include a label with the generator name and location, and a hazardous-waste label.

DANGER ASBESTOS May Cause Cancer Causes Damage To Lungs Authorized Personnel Only Wear Respiratory Protection And Protective Clothing In This Area |

Figure A-2. Appropriate wording for warning sign to demarcate areas where the PEL or excursion limit may be exceeded due to asbestos handling or the presence of damaged, friable ACM in need of repair.

Appendix B. Berkeley Lab Asbestos Work Permit

This permit is used to supplement the standard controls specified in the Berkeley Lab Asbestos Program Document and EHS0316, EHS0322, and EHS0364.

__________________